Hello to fans who love to craft, in this instruction we will look at how to make a jigsaw machine from an old sewing machine. It is possible to cut rather thick materials on such a machine, of course, the machine is not designed for very accurate and accurate cutting, but the cutting quality is quite good. In fact, the sewing machine is already a ready-made jigsaw machine, there is a reliable unit that converts the torque from the engine into reciprocating movements of the saw. You only need to slightly change the design and homemade ready. If the project interests you and you need such a homemade product, I propose to study the project in more detail!

Materials and tools used by the author:

Material List:

- old sewing machine;

- an engine of suitable power;

- Belting;

- plywood;

- round timber;

- bolts;

- sheet metal;

- channel;

- profile pipes;

- plastic ties;

- cutting blade from a manual jigsaw.

Tool List:

- ;

- Miter saw;

- ;

- ;

- taps for threading;

- paint;

- wrenches, screwdrivers.

Homemade manufacturing process:

Step one. Sewing machine preparation

We will prepare the sewing machine, we need to remove all unnecessary. To begin with, we disassemble the lower part, unscrew the connecting rods, we need to completely remove the base from the machine.

Next, on the sewing machine in the back there are two rods, we leave the one that moves, on which the needle is attached. The other stock needs to be removed, it is not needed. At the same time, we lubricate all moving parts, since the load on the sewing machine will already be more.

Step Two Machine frame manufacturing

We make a frame for the machine, first you need to assemble a frame like a regular table, only strong. As material we use profile pipes.

Next, you need to make a bed, that is, that part of the frame on which we will install the part from the sewing machine. The bed should be strong, as the machine will be supported by only two bolts. As a material, the author uses a piece of the channel. Cut off, weld the mounting ears and securely weld the channel to the frame.After that it will be possible to fix the sewing machine on the bed.

Step Three Fastener

We make a fastener with which we will install hacksaw blades. We need a round timber, we drill a hole in it for the stock of the sewing machine, as well as a hole for the fixing screw.

It remains to make a retainer for the knife, cut a slit hole in the workpiece with a hacksaw for metal, and then insert the knife into the slot and weld the slots on the outside so that the saw has something to rest against. But when welding, you need to make sure that the saw itself is not welded.

We will clamp the canvas with two bolts, drill holes for them and cut the thread.

Step Four Emphasis

For the hacksaw blade you need emphasis, otherwise it will vomit when cutting. The emphasis needs to be welded to the frame. Here we need a piece of round timber, the author made a drink in it and welded it in its place. To reduce friction and increase the life of the machine, it is better to replace this part with a bearing.

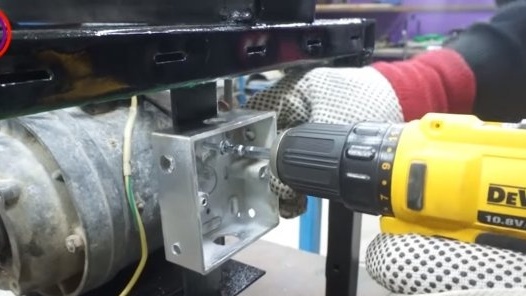

Step Five Engine installation

We install the engine to understand where it should be, we install a belt. The mounting part is very simple, it is a piece of sheet iron, which is welded to the frame on racks of the right length. The racks are made of thick iron plates. The engine itself rests on a clamp, it is pressed to the base, the clamp is an iron plate with two threaded rods that are welded to the base.

Step Six Countertop

We make the tabletop, here we need plywood or OSB. We simply screw the countertop to the frame with self-tapping screws. Do not forget to make a hole for the cutting blade. The machine after that will be almost ready, proceed to painting.

Seventh step. Painting and assembly

We paint our machine, blow out everything rusting with a spray can, now the machine looks great. We also paint and countertops. After painting, the machine can be assembled, we attach part of the sewing machine to the frame, and we also fasten the countertop.

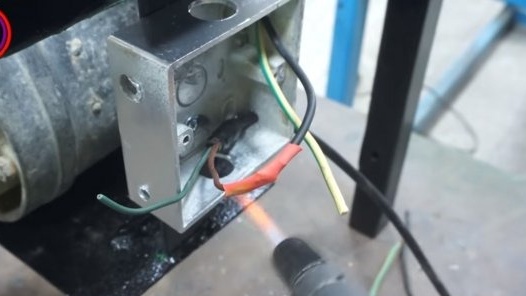

We install the engine, the author installed a capacitor near it with plastic ties. We also install the switch, the author has a keyboard type, convenient to use. We carry the cable along the frame and fix it with plastic ties so as not to interfere.

The car is ready, you can test. We install the cutting machine tightly and start the machine, the author easily cuts such fairly hard and thick material as chipboard on the machine, the machine easily copes with the task. It will also be easy to cut boards, plastic pipes and other similar material.

On this project can be considered completed, I hope you liked the homemade. Good luck and Tver inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!