In this article, the author of the YouTube channel "Creative forging" will tell you about the technology of forging a "pigtail" or "spikelet" of steel round timber.

Materials

- Steel round 10 mm diameter.

Instruments, used by the author.

-

- Welding machine

- gas cutter

- metal brush

-

- Cutting disc

- Metal wire brush

- Vise, anvil

- Hammer, ticks.

Manufacturing process.

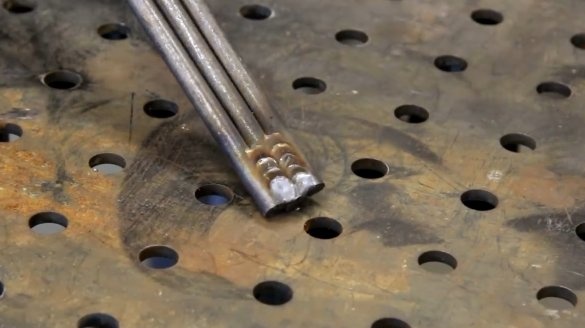

As a material for this homemade work, the master will use a steel round log with a diameter of 10 mm. A thinner bar, 8 or 6 mm, is also suitable. He cuts three workpieces 600 mm long. Then it welds them together on one side.

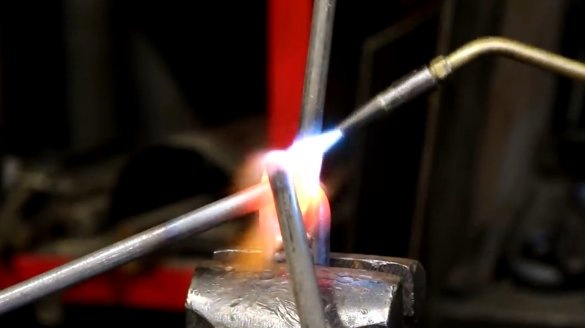

Clamps the workpiece in a vise, and begins to heat up the rods as close to the weld point as possible.

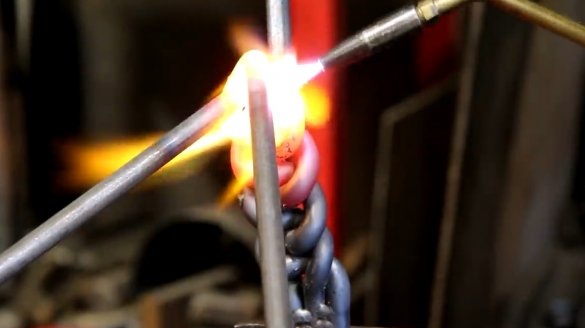

Now begins to weave a pigtail. The bar that bends at the moment is warmed up to the maximum. If you will be doing this for the first time, then you should practice using a thin aluminum wire or plasticine. Bars should be woven as tightly as possible.

Completes the braiding, and bends all three rods up.

At first glance, the workpiece does not look very uniform. The master removes scale from it with a metal brush.

Then he ignites the gas hearth and heats the workpiece.

Now follows the manual straightening step with a conventional hammer. And again descaling.

Again heats the workpiece, and processes it with a pneumatic blacksmith hammer, forming four faces.

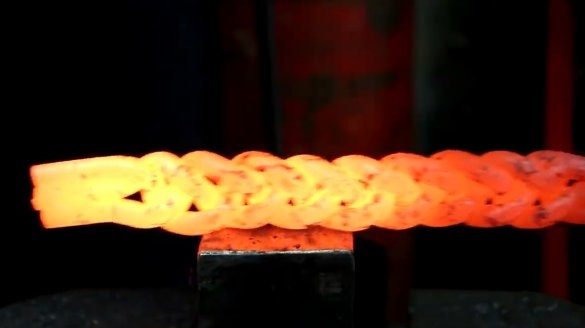

This is what a hot workpiece looks like. Last time, it cleans the scale manually.

There was only a finishing stripping with a grinder with a wire brush.

That's all, the product is ready. It can be used, for example, to decorate the arms of fireplace sets. There is already a matter of your imagination!

Thanks to the author for an interesting forging workshop!

All good mood, good luck, and interesting ideas!