I welcome fans to knock on red-hot pieces of iron, today we will consider how to make a small shovel by forging. Such a shovel will be useful in the household for small jobs, and it will also be more convenient for it to work more fully if you have metal detector. The author forged a blade from a round timber; the process is not complicated, but it takes time and considerable physical effort. The author carries out some work with an automatic hammer, but basically everything happens manually. The blade looks great, and it is very strong, the metal is thick, and even strong due to forging. If the project interests you, I suggest studying homemade in more detail!

Materials and tools used by the author:

Material List:

- round timber (preferably using strong steel);

- bar for the handle;

- brass tube;

- linseed oil.

Tool List:

- automatic hammer;

- an anvil, hammer, forge, and more;

- ;

- vise;

- lathe;

- paper, pencil, scissors.

The process of manufacturing a shovel:

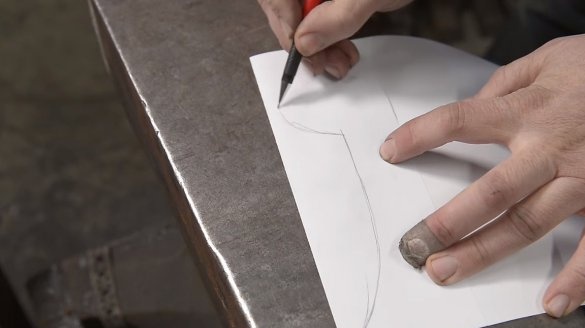

Step one. Template

To begin with, it is recommended to make a shovel template, according to which we will be guided in the manufacture of homemade products. Fold the sheet of paper in half and draw one half of the shovel, then cut out the template. As a result, we get a spade template with identical halves, everything is quick and easy.

Step Two Forging

Getting to forging, our task is to get a workpiece from round timber. To begin with, the author pulls one side on a round log and forges a rectangle, then you can reliably grab onto this part with a grip.

We heat up the workpiece, by cutting we cut off the excess, then we need to forge the round timber under the cone. At the next stage, we forge the round timber along its entire length so that it becomes flat. Well, then a little patience and strength, the result is a workpiece, already remotely similar to a shovel.

Step Three Completion

We have an excellent forged blank for a shovel, we take our template from paper, apply and trim the excess. As a result, we get the contour of the shovel. We eliminate minor defects with a metal file.

Then again we heat up the workpiece, form a shank, it will go into the hole made in the wooden handle. We also bend the shovel to obtain the desired profile. As for the cutting edges, it will also be useful to forge them. At the end, the author puts his mark on the shovel.

Step Four A pen

We make a small handle for a shovel, here the author needed a lathe. The starting material can be a bar, stick or other part of the tree. A brass ring is installed in the nose of the handle so that the shank of the shovel does not split the handle and everything holds tight. Of course, the ring may be iron, but brass looks more solid. Grind the handle well to a smooth state and saturate it with oil so that it is not afraid of water. And you can cover with varnish, then the handle will be washed.

Step Five Shovel sheeting

The shovel is made of iron, which will rust quickly. We need to cover it with a protective coating, for such purposes, you can use linseed oil. We heat the shovel with a gas burner, apply oil, burn. We repeat the procedure several times, as a result, a black film forms on the shovel, which will not allow the iron to rust.

That's all, the shovel is ready, we press on the shovel handle and homemade can be tested. The author works with a shovel in a flower bed. Of course, it would be nice to sharpen a shovel, so it will work much easier and she will be able to chop roots. On this project can be considered successfully completed, I hope you liked the homemade. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!