In this article, the Wizard will tell us how he made a simple loom. For the manufacture of the machine does not need expensive

Tools and materials:

-Plywood;

- PVC pipe ø 25 mm;

-Wood dowel;

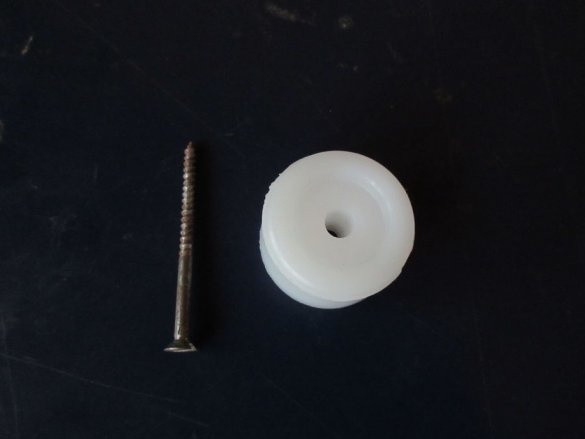

-Wheel made of nylon;

-Screw;

-Silicone sealant;

-Drill;

-Dremel Ultra;

-Crowns on wood;

-Roulette;

-Marker;

- Hacksaw for metal;

-Nails;

-Hammer;

- Joiner's glue;

-Acrylic;

-Threads;

- Sticks for ice cream;

Step One: Sawing

The length of the plywood sheet that the master had was 61 centimeters. The length of the machine will be the same length.

5 blanks need to be cut from the plywood sheet:

-7.5 cm * 61 cm;

-30.5 cm * 7.5 cm - 2 pcs;

-28 cm * 20 cm;

-20 cm * 7.5 cm;

Step Two: Holes

Now, on the uprights and on the longitudinal board, you need to make holes. Marks the center line on all three workpieces. On vertical posts, it drills three holes: two from above at a distance of 4 cm, 15 cm, and one from below at a distance of 5 cm.

On the longitudinal board, a hole at a distance of 36 cm from the back. The master cuts the holes with a crown on a tree of 25 mm.

Step Three: Cutout

To tension the thread on a long board, a wooden dowel will be installed. To install the dowel in the board, a groove of 13 * 0.6 cm is cut out.

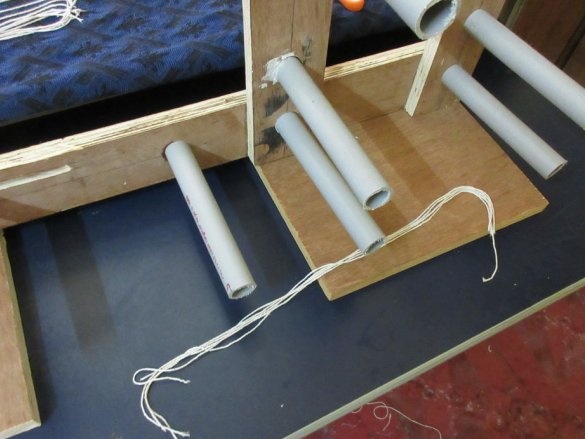

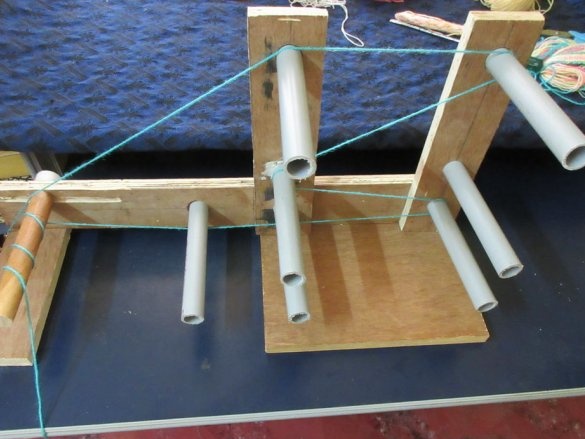

Step Four: Frame Assembly

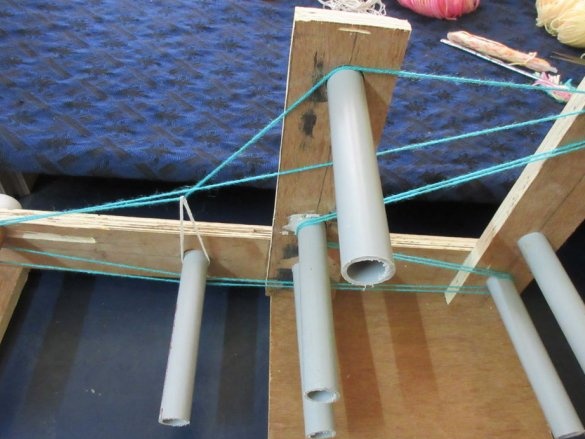

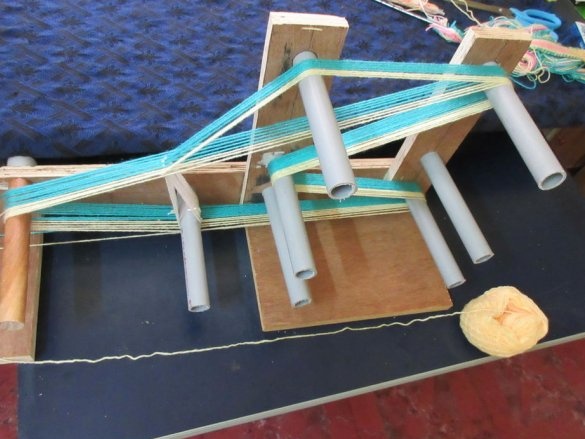

Now we assemble the machine, as in the photo. Apply joiner glue to the joints. Fixes parts with nails. One vertical stand is mounted on the edge, the second after 28 cm.

Fastens the assembled assembly to the support board.

A hole is drilled at the end of the dowel. Installs the dowel in the slot, and screws a nylon wheel into the end.

Fixes another board under the dowel with screws screwed on the side surface.

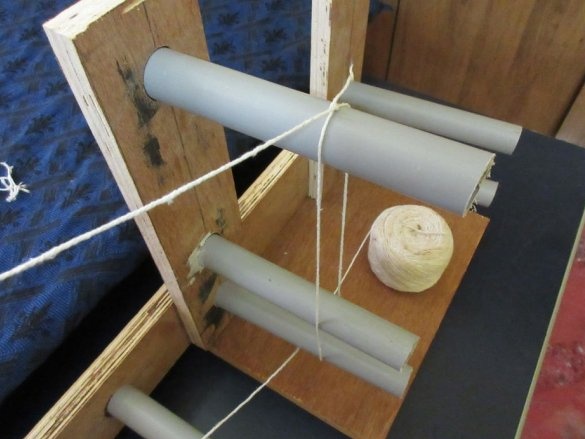

Step Five: PVC Pipes

Cuts seven pieces of PVC pipes of 18 cm.

Installs in the holes of the machine.

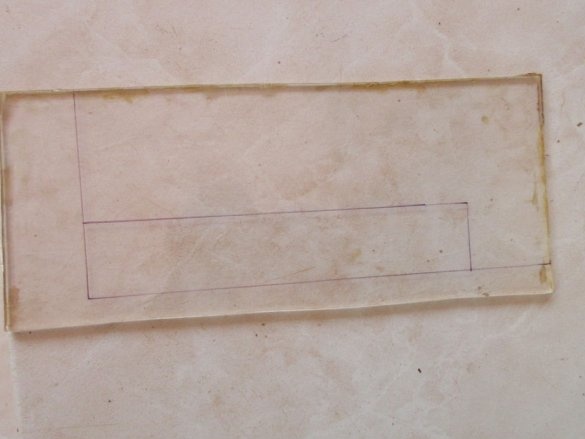

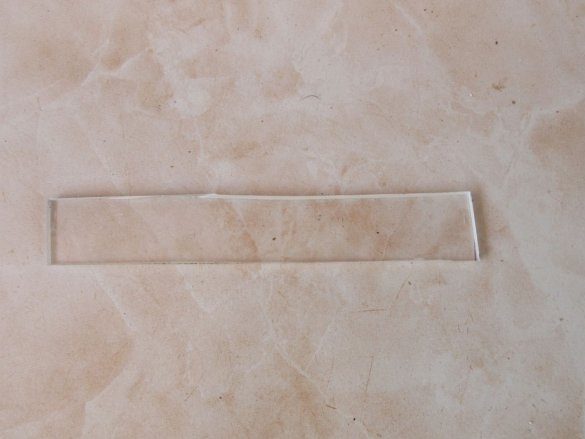

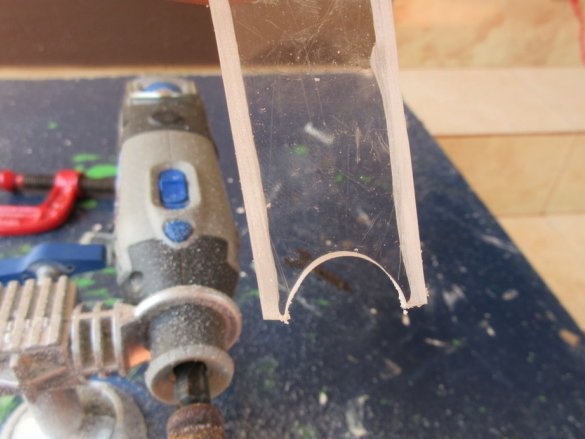

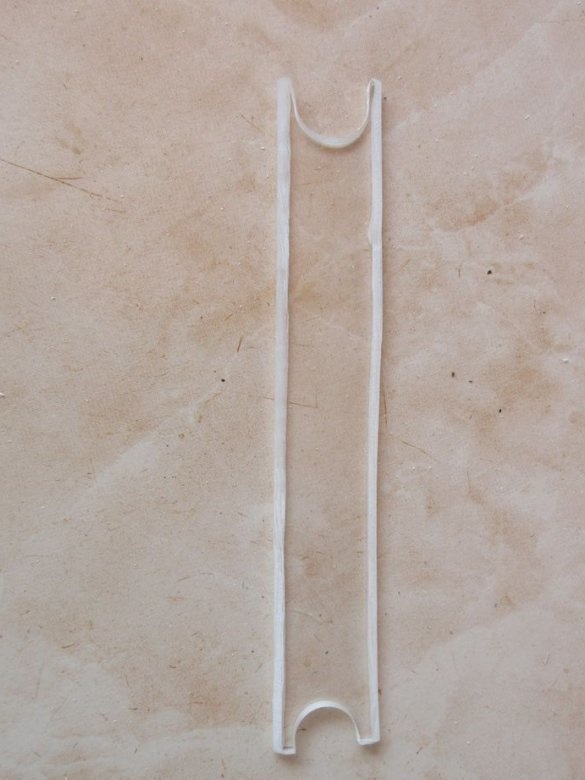

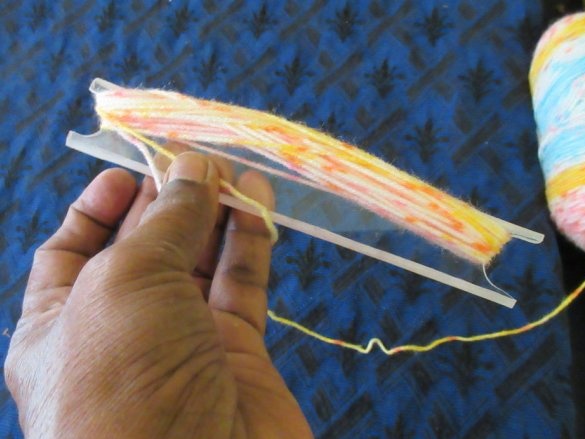

Step Six: Shuttle

Weaving bangs, this is the working body of the loom, laying a weft (transverse) thread between the warp threads during the production of fabric.

Shuttle master cuts out of acrylic.

Seventh step: work on the machine

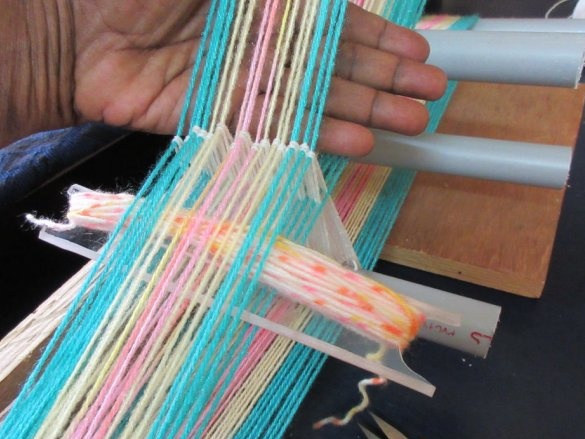

Then the master proceeds to weaving. For work, you will need threads of different colors and sticks for ice cream.

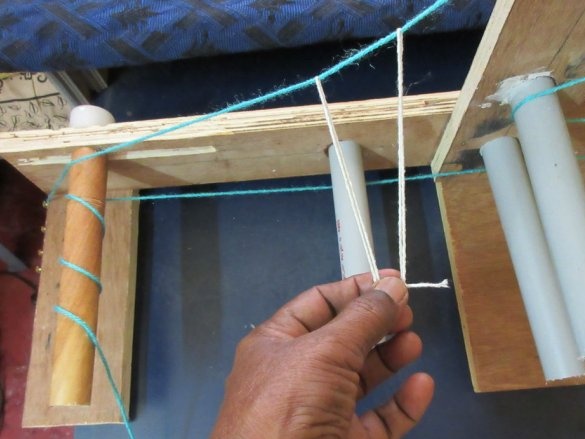

Imposes a loop of white thread.

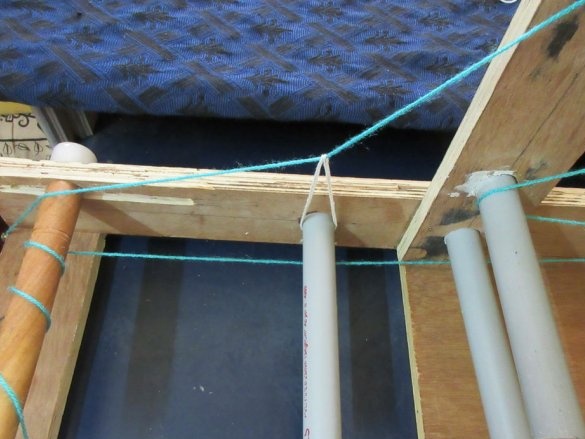

Tie the end of the thread to the screw. Stretches the thread, as in the photo.

Next you need a loop of thread. Wrap around the colored thread and put on the lower tube.

Further, depending on the color scheme of the canvas, it continues to wind the threads according to the same pattern.

When the desired web width is reached, the ends of the threads are bonded.

Now you need to skip the transverse thread. First, the thread is wound on a shuttle. Then you need to separate the wound threads. To do this, just press on the canvas for white loops. A shuttle with a thread is stretched into the gap between the threads. The thread is “tamped” with a wooden stick. Then the shuttle is pulled out and the canvas is released.

Continues to weave, moving the fabric in a circle.

When almost all the fabric is woven, the tape is removed from the machine. Loops are pulled out (they can be used in the next work). Now you can cut free threads and knit at the ends.