Hello fans to craft, I propose to consider useful homemade for the garage and not only. We will talk about a press with an electric drive, such a press can easily chop wood, remove and install bearings, and so on. The machine operates on the basis of a gear induction motor. The machine easily splits logs, breaks several layers of plywood, squeezes profile pipes and more. The machine is assembled quite simply, but not many materials are needed. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- threaded shaft with nut;

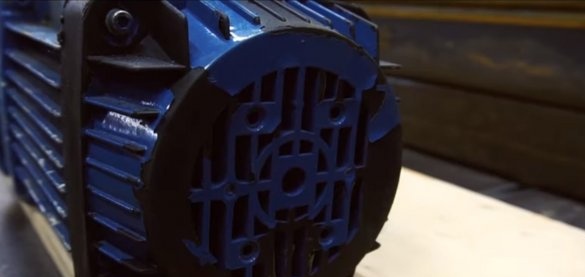

- asynchronous motor with gear;

- ;

- wiring, switch;

- channel;

- profile pipes;

- threaded rods, nuts, washers (for mounting the engine);

- round pipe.

Tool List:

- welding machine;

- ;

- ;

- screwdriver;

- ;

- spanners;

- tape measure, marker.

Homemade manufacturing process:

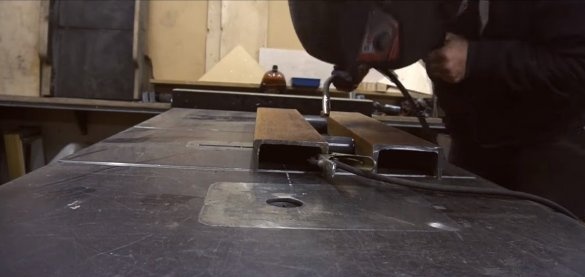

Step one. Base and frame assembly

Let's start with the basis for the machine, the installation will be quite heavy, and with a heavy engine at the top, the machine can also be unstable. We make the basis of the channel, we cut the material into the necessary pieces and weld. As a result, the design should resemble the letter "H".

Now we need to make two racks, for them we use a profile pipe of large diameter. We cut the pipes and clearly parallel weld to the base. That's all, at the end we weld to the upper part a channel piece for installing the engine and the frame is ready.

Step Two Moving part

A platform will be moved along the drains, to which a threaded shaft from the engine will be connected. On the same platform, the working rod of the machine will be installed, which will press on the product during operation. For the construction, two pieces of the profile pipe will be needed, drill holes through their center with crowns and weld a piece of a round pipe. The working shaft of the machine will go into this pipe.

As a result, it remains to make guides, cut the profile pipe so that the corners turn out, and then weld them along the edges of the platform.As a result, around the racks should be pipes that will ride on the racks.

Step Three Engine installation

The engine must be installed in the upper part of the machine, and it must be fixed securely, since it is this mount that will take on the proportional loads of the working rod. We drill holes for threaded rods in the frame, and also drill a hole in the center for the motor shaft with a crown. We fasten the engine with threaded rods and nuts with washers.

Step Four Installing the working shaft

The working shaft must first be made, namely, we need to weld the motor shaft and the threaded shaft together. The author puts the shafts on a flat table and seizes welding. We roll the shaft on the table and see if everything turns out smoothly. Well, then it remains to boil the shaft well and clean the weld. We weld the nut of the threaded shaft to the moving platform.

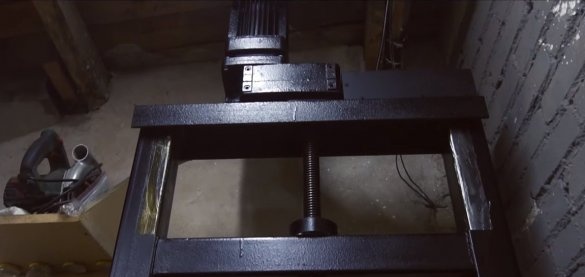

That's all, the homemade product is ready, we lift the car from the table, carefully lower it to the floor, the homemade product weighs a lot. We drag her around the garage and thereby swing different muscle groups. Here's a great muscle trainer.

We’ve trained and that’s enough, we install the car under the wall, then it is highly advisable to screw it to the wall, otherwise, if the structure falls on you, it will kill without a doubt.

Step Five Thrust pad and assembly

We will make a persistent platform from the channel, and for its fastening we drill holes in the racks and make strong iron rods. Now the platform can be easily installed at the desired height.

We paint the car so that the machine does not rust. We install the switch, it should be reverse with us.

That's all, you can experience homemade. The author stabs on a log machine, as well as crushing various iron parts. The project can be considered successfully completed, I hope that the homemade product was useful to you, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share with us your ideas and homemade products.