Many of you probably thought about how to paint wood, and especially suvel and burl. They make very beautiful products.

In this article, Ben, the author of the Ben's Worx YouTube channel, will tell you about the method of impregnating the mouthpiece with pressure. This technology definitely needs a pressure chamber. About her independent production of PVC pipes is described in detail in this article.

Materials

- Cap or suvel

- Water based acrylic dyes.

Instruments, used by the author.

- Pressure chamber

- Oven.

Manufacturing process.

So, the author prepared pieces of birch burl and dye.

In a separate container, he pours water, and adds a water-based dye. Then mixes. The first staining will be done in red, then blue. Let's see what color will better paint the workpiece and impregnate its surface.

The author drops a piece of the cap in the solution, and puts the plastic cup in the pressure chamber.

Then it pumps up pressure in the chamber to 3 atmospheres, and leaves it overnight.

A bit of debris appeared on the surface, these are the remnants of dust from cutting a block.

And here it is the result - the next day the cap acquired a reddish tint.

Now he dries the wood in the furnace, and, apparently, the paint faded somewhat, but was preserved.

When compared with the source material, the processed workpiece really looks more interesting.

Further, the author repeats the experiment with blue paint. This time he made the solution more concentrated.

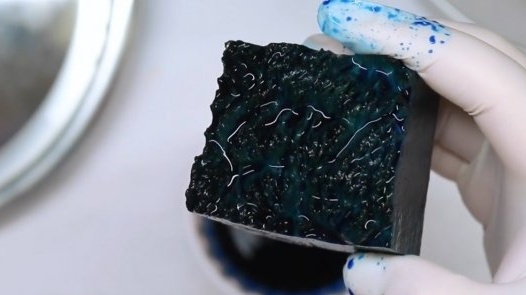

And again, after 24 hours of processing in the pressure chamber, he takes out the workpiece.

Then repeats the drying process. And this time the shade turned out to be more saturated, since the paint had a deeper and darker color. Wood has better absorbed dark paint.

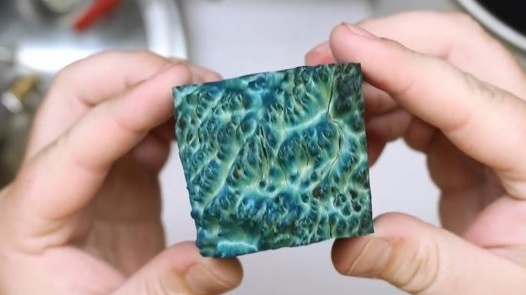

Now compare with the original color. The paint worked pretty well, right? And all thanks to the pressure chamber.

This is such an interesting texture for the cap. In the future, this author will fill this cap with epoxy resin and turn it into a work of art.

It is interesting, but if the wood is evacuated in a dye, and then pressurized, will the impregnation be deeper?

Thanks to the author for a simple but important technique for wood impregnation!

All good mood, good luck, and interesting ideas!