Wooden shoes are the traditional shoes of commoners in Western Europe. These shoes also performed protective functions protecting the feet from falling heavy objects.

The master decided to improve a little wooden shoes and installed a roller in his heel. Now in shoes you can not only walk, but also ride.

Tools and materials:

-Wood;

- Joiner's glue;

-Super glue;

-Insoles;

-Varnish;

-Laces;

-Rollers;

-Chainsaw;

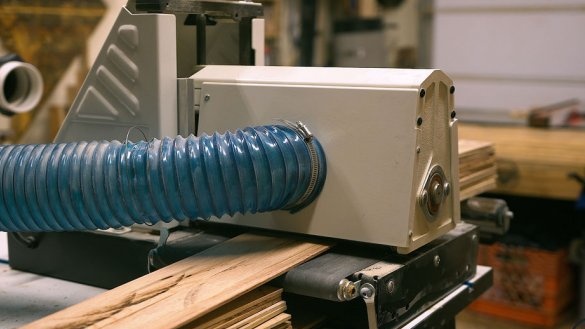

- Planing machine;

-Laser level;

-Grinder;

-A circular saw;

-Marker;

- Clamps;

-Bandsaw machine;

- Burnout;

-Electrostameshka;

Step one: making blanks

At first, the master wanted to make maple shoes, but the maple block was rotten.

Then the master used boards from pallets. I drove the boards through the planer. Sawed to size. Glued the block. The upper parts of the shoes will be made from this block.

For the soles, the master dismantled the pallet. Planked off. Sawed into thin blanks. He quipped again.

The width of the veneer is less than necessary and the master glues strips of the desired width.

Step Two: Bonding Workpieces

Before gluing the sole to the shoe, the shoe blank is sawn into two parts, and then the shoe nose is sawn. Now you can glue the veneer and glue it to the shoe. The glued sole is pulled together with clamps and repeats the shape of the shoe.

After gluing, the clamps are removed, the shoes are trimmed and ground.

Step Three: Form, Inside

It processes workpieces of shoes giving them the desired shape.

Now you need to cut the inside of the shoes. First, the master cuts out the heel.

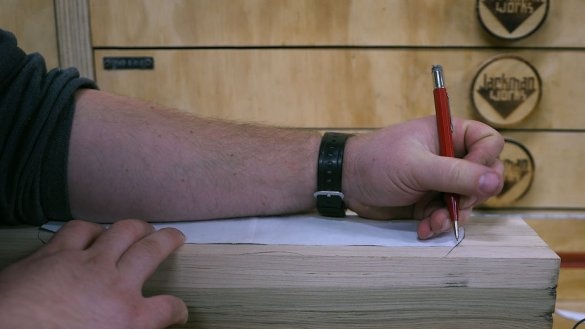

Further marks out the central line and saws the shoes into two halves.

Hollows out cavities inside halves of shoes.

Using a clamp, temporarily connects the halves for fitting. Then it adjusts in the right places.

Step Four: Roller

Cut a niche for installing rollers in the heel of the sole. Glues halves of shoes.

Step Five: Detailing

Now you need to give the shoes a normal look.The master draws and cuts lines, contours. Cuts the sole pattern and lacing position.

Burns seam and label.

And with the last step the master varnishes shoes puts an insole in shoes.

Wooden shoes are ready.

The manufacturing technology of shoes can be seen in the video below.