Greetings to all lovers of fire, steel and hammer. Today we will look at how do it yourself make a forge furnace. Homemade made of metal, mainly a corner and sheet metal. The furnace is equipped with a dome through which smoke and other toxic gases escape, and if desired, walls are installed on the furnace so that wind does not blow into the hearth. In the case, the author did not show us the homework, but visually there is no doubt about the operability of the furnace. If you are interested in the project, I propose to study it in more detail!

List of materials and tools that the author used:

Material List:

- refractory brick;

- iron corner;

- sheet metal;

- blower;

- switch to control the blower;

- paint for metal (optional).

Tool List:

- a drill and good drills for metal;

- grinder;

- welding machine;

- tape measure and chalk;

- a vise.

Furnace manufacturing process:

Step one. The foundation

First of all, we will make the basis where the refractory brick will be laid. To begin with, we weld a rectangle of the required size, well, and then, depending on the length of the brick, weld the corners to the frame. As a result, heat-resistant bricks will be laid in a circle, and in the center will be a thick iron plate with holes through which air will be pumped, these will be grates.

Step Two Racks

We weld the racks to the resulting structure, here we also use an iron corner. The height of the racks should be such that a dome can still be installed on top of the hearth. Later, the author will weld the racks to each other from the bottom to improve the rigidity of the structure.

Step Three Dome

We assemble the dome; for its manufacture, the author used sheet metal. Just cut out the four parts in the form of pyramids, and then weld them into the dome. It is advisable to make welds sealed so that smoke does not pass.

Step Four Air supply sleeve

This element of the furnace is the most complex, a blower is installed on it, there is a damper, and grates are installed on this part of the furnace.

To start, weld the frame from the corner. Next, we assemble a rectangular pipe in accordance with the frame, weld it from sheet iron. There should be a hole on the side of the pipe, through which the blower will blow air into the furnace.

As for the damper, it is located at the bottom of the pipe, just opposite the grates.With this damper we can clean the sleeve of ash, and also with it you can adjust the air supply to the furnace. The damper is cut out of sheet iron, and the guides are made from the corner and welded to the pipe.

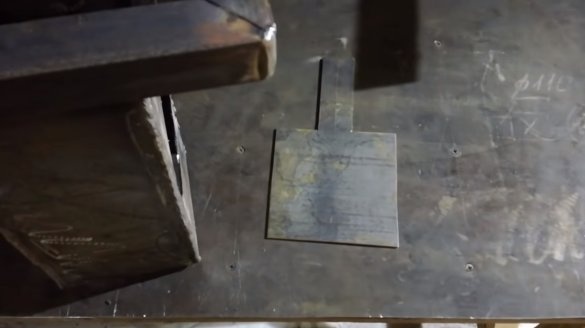

Step Five Grate

We make grates for the furnace, through them we will blow air. For such purposes, we need thick sheet metal, it is better to use cast iron or stainless steel. We cut out the rectangle of the required size, make the markup and drill rows of holes. The drill should be quite strong and high-quality for such work, it is better, of course, to use a drilling machine.

Step Six Blower installation

We install a blower on the oven, this can be done by ourselves. The blower is equipped with a damper for adjusting the volume of forced air. We weld an iron ring to the feeding sleeve and install a blower using a round pipe. As a fan, you can use a fan to arrange ventilation in the house. Well, if the fan speed can be adjusted, this will reduce energy consumption and extend the life of the fan. However, a dimmer can be installed on any fan, but they cost a penny in China.

To control the blower, install the switch in a convenient place and isolate the wiring well if you have a 220V fan.

Seventh step. Final touches

At the end, we lay on the basis of refractory brick. The author also decided to install a branch pipe for the chimney on the dome, if desired, it will be possible to put a visor here so that the rain does not interfere with the work.

As a result, it remains to make side walls of sheet iron, the author has welded hooks to them, and they just hang on the frame. If desired, the side walls are easily removable. Thanks to the side walls in the furnace there will be a shadow and it will be clearly visible what color the red-hot piece of iron glows with.

On this project is over, I hope you liked the homemade. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!