A vise is one of the most necessary tools in a workshop, but what if you need to fix a pipe or a round timber in them for processing?

In this article, the author of YouTube channel "Be Creative" will tell you how he made a pair of special jaws for a vice.

Their design is very simple, and for the manufacture of this homemade product does not require expensive materials and time.

Materials

- Steel corners

- Spray paint.

Instruments, used by the author.

- Marking pencil

- marker

-

- Cutting and flap scraping discs

- Miter saw

-, vise.

Manufacturing process.

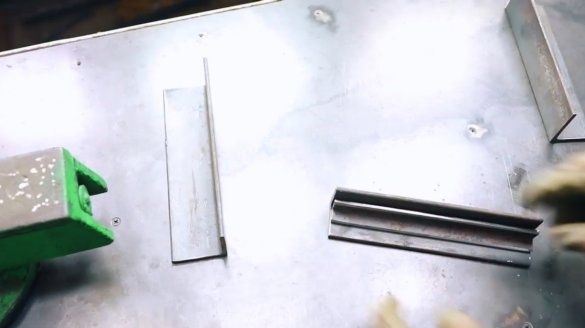

So, the author prepared several steel corners for making homemade products.

Then he marked the workpieces along the width of the regular jaws of a vise.

The author got two main corners, and two additional ones. The length of the workpieces is the same. The resulting blanks will need to be welded together at an angle of 45 degrees.

One of the corners needs to be shortened a little, the author marks the place of the cut with a marking pencil. By the way, about its manufacture there is an interesting article.

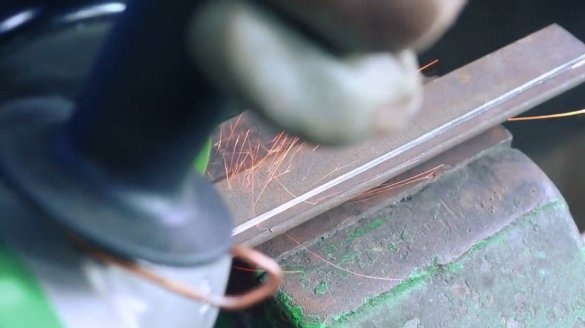

It fixes the workpiece in a vise, and cuts off excess. Edges of corners are polished by a petal stripping disk.

On the main corners marks the future place of welding.

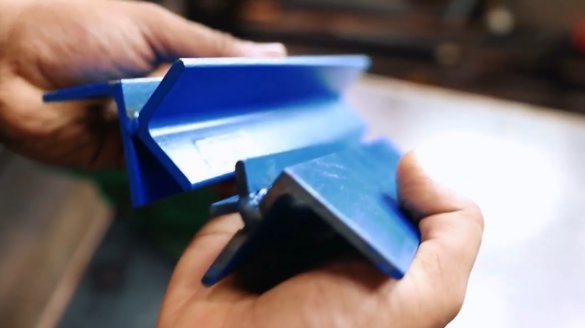

It remains only to weld to the main corners of the large and small corners.

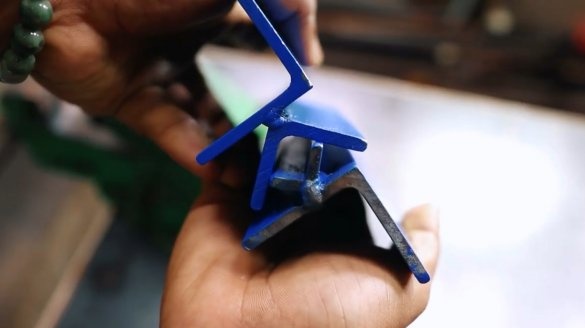

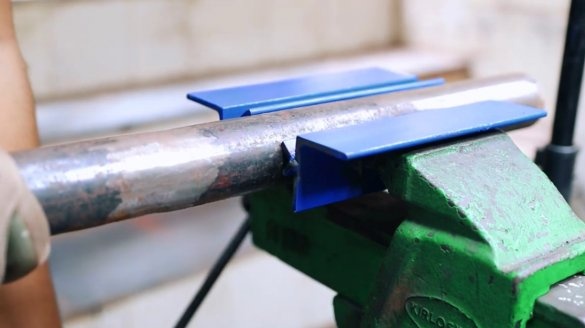

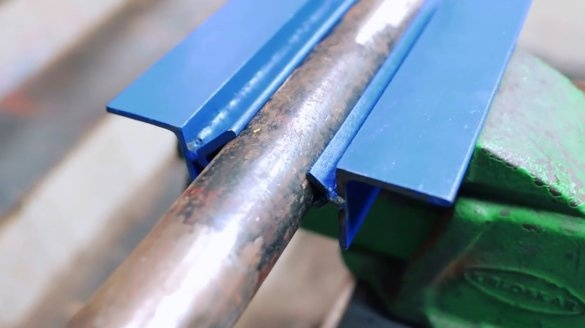

After spray painting device looks like this. Can be installed in place.

Now you can easily fix pipes and various roundabouts in a vice. If it is necessary to fix the parts in a vertical position, additional angles can be installed, for example, as described in this article. Only there the manufacturing complexity is very high.

Thanks to the author for a simple but useful tool for the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.