Everyone knows various special knives and cutters for working with veneer, but not all of them are suitable for especially thin and complex trimming of the edge, or for obtaining long and narrow strips.

In this article, the author of the HeARTwood YouTube channel will tell you how he made a fairly simple but highly specialized veneer cutter.

Materials

- Solid oak and sapele

- Blade

—

- Wood screws.

Instruments, used by the author.

—

—

—

- Hand planer

- Japanese saw, square, caliper, pencil

- Chisels, gantry.

Manufacturing process.

So, the tool will consist of two different types of wood. The first master processes the oak board.

Marks and cuts a rectangular workpiece suitable for the size of the hand.

The ends of the workpiece are carefully planed with a planer.

One of the corners of the master rounds off with a wide chisel.

Mandatory checks the workpiece on a flat surface.

Now you can begin to manufacture the second part of the body. The master decides to make it from wood of a different color, this is sapele. Thus, the place of cut will be clearly visible. This material is quite difficult to process due to the unusual structure of the fibers.

Now it connects both workpieces to each other, and fixes it with a clamp. Their bottom surface should be as flat and flat as possible.

Then he drills the pilot holes with a countersink drill and temporarily fixes it with short self-tapping screws.

Once again he thoroughly planes the bottom face, checking it with a square for perpendicularity.

Now the master needs to make the blade itself. He acquired a wide blade 0.2 mm thick.

Then marks out, and cuts off with a dremel a piece of a blade 40 mm long. Also removes burrs at the cut site.

Disassembles the body, and marks the perimeter of the blade. In this case, the blade is located at a slight angle to the base, and at one edge protrudes 1.5 mm.

By marking, makes shallow incisions with a chisel.

An important step is cutting the recess for the blade. It is necessary as a stop and position lock. Using an excavator cuts a recess 0.15 mm deep.

Tries on trying on all the details, and then drills pilot holes of already greater depth, connects the parts of the case with long self-tapping screws.

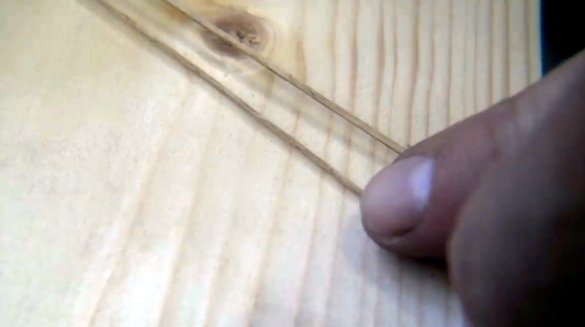

Now, taking a sheet of veneer, sets the position of the pressure rail - stop, focusing on the junction of the two parts of the body. In this case, he makes an offset from the junction of about 2 mm.

That's all, with a single movement, a narrow strip of veneer is easily cut off.

At the same time, the cut of the edge of the veneer is perfect, without burrs and cuts.

There remains the final processing of the tool body. Sharp corners are cut off and rounded off.

The surface is also machined with loops and chip removers.

Now it remains to soak all the outer surfaces with linseed oil or wax.

To install and replace the blade, the entire case does not need to be disassembled, just release the screws slightly.

Previously, the author had already made a vein cutter, but the new one turned out to be better, and lies more conveniently in the hand.

Thanks to the author for the simple but useful device for working with veneer!

All good mood, good luck, and interesting ideas!

Author video can be found here.