Hello to all fans of craftsmen, today we will consider how to make a simple, compact portable pump. Such homemade You can pump water from a lake or other sources, the water level in which is at a shallow depth. Self-made battery or 12V power supply works. The pump casing is made of plumbing parts, and the well-known c. Going homemade is quite simple, at home device can be quite helpful. If desired, you can put a speed regulator on the pump to control the water pressure. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- ;

- bicycle spokes;

- adapters for connecting shafts;

- speed control for the engine;

- plumbing parts (pipe, plugs, tee, etc.);

- a piece of rubber from a bicycle chamber;

- cogs;

- copper wire;

- epoxy adhesive;

- a propeller with a diameter of 4 mm;

- a piece of tubule from the antenna.

Tool List:

- a hacksaw for metal;

- glue gun;

- soldering iron;

- marker;

- drill;

- scissors;

- a screwdriver.

Pump manufacturing process:

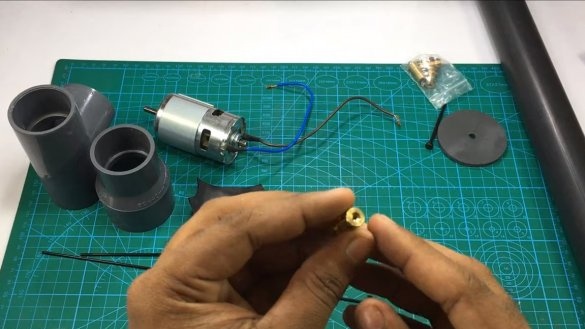

Step one. Shaft and housing

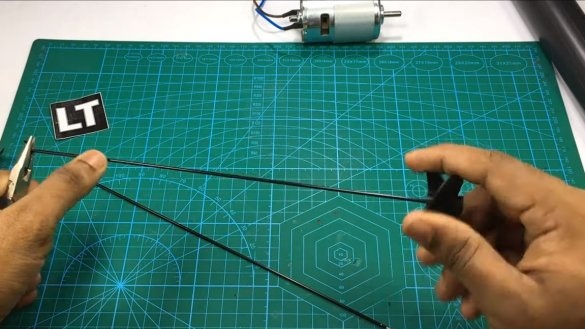

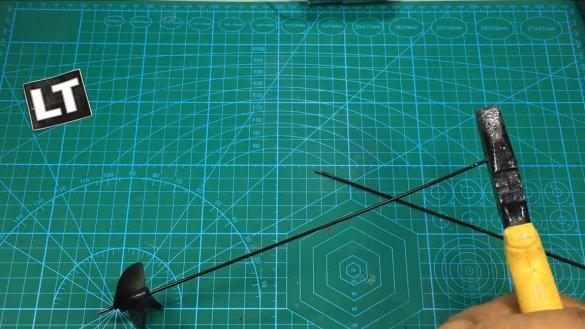

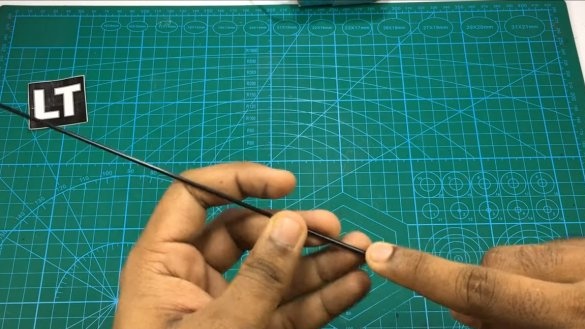

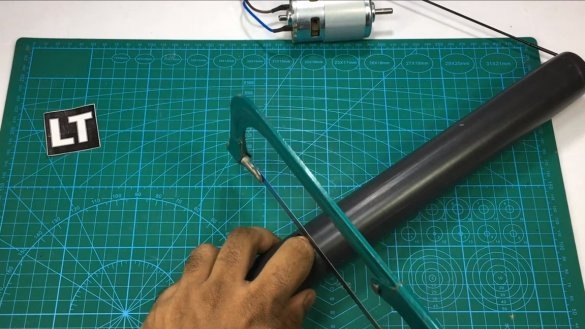

First of all, we will make a working shaft, its author made of two bicycle spokes. The needles must be joined together, for this we need a piece of the tube from the antenna or a similar tube. A rubber tube or the like will do, then you won’t need to center the shafts.

We install a propeller with a diameter of 4 cm on the shaft, it is advisable to glue it, you can use epoxy glue or superglue.

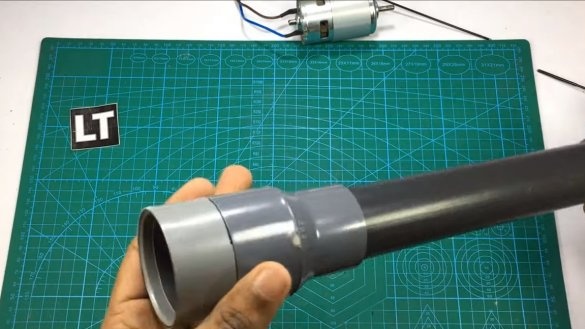

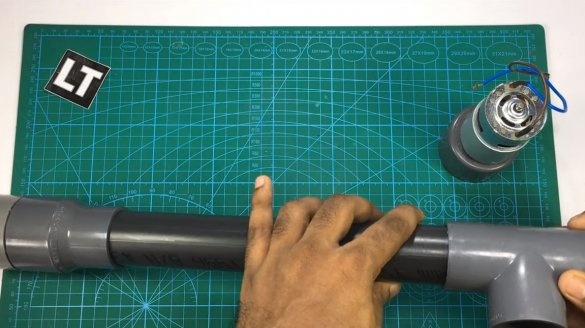

Now, in accordance with the length of the shaft, you need to assemble the pump casing, we make it from a piece of pipe and a tee in the form of the letter "T". A cone-shaped part is installed at the end of the pipe; the propeller will rotate in it.

Step Two Engine installation

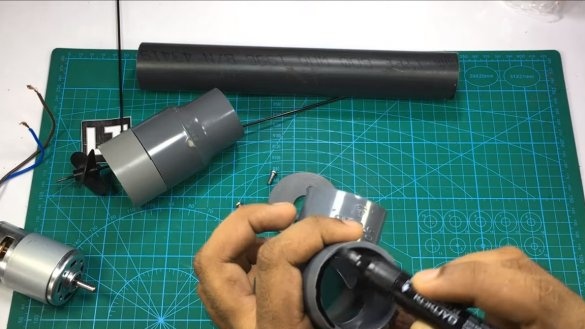

The engine must be mounted on the pipe plug, then this plug is mounted on the tee. We drill three holes in the plug, under the shaft and under two screws.You also need to make a washer out of plastic so that the housing with the bearing does not protrude inside the plug.

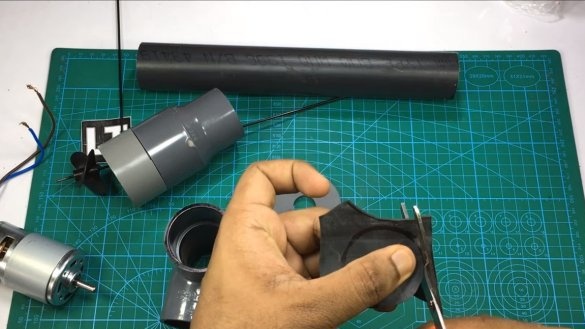

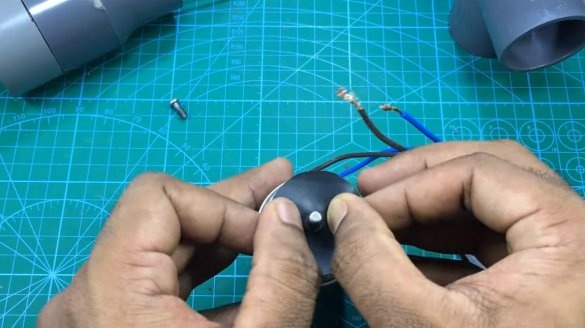

It is important to isolate the engine well from water, otherwise it will quickly fail. To do this, we need to make an oil seal, we use rubber from a bicycle chamber as a material. We cut out a circle and punch holes, make a hole for the shaft smaller in diameter so that the gland tightly compresses the shaft. We fasten the resulting oil seal with screws and fill in a circle with a good layer of hot glue.

Step Three Shaft installation and homemade assembly

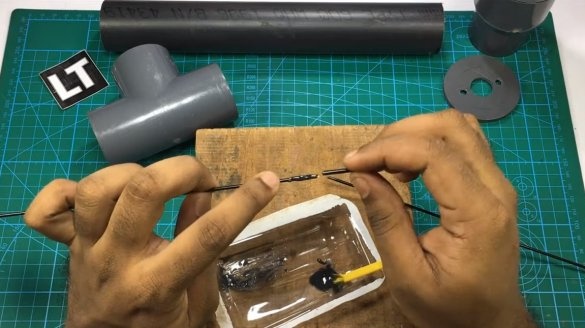

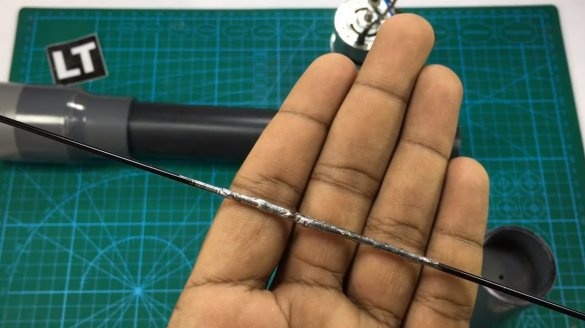

At the end, we will assemble the working shaft, we need to join two spokes, we can use a brass tube for this from the antenna of the radio receiver. The best connection is soldering, so everything will hold tight and reliable. In addition, epoxy glue can also be used.

Having assembled the shaft and installing the propeller, we now need to install the shaft inside the housing. The shaft needs stops, the support on which it will lie. We make stops from copper wire, drill holes and glue their body. To reduce the water pressure on the gland, the author made another washer made of plastic, it is best for reliability and install an oil seal on it.

As a result, it remains to install the shaft and connect the motor, install the adapter on the shaft end, and then install the motor, the axes are connected through the adapter using superglue.

That's all, now the homemade product is ready, you can experience it. The author's video shows how the pump shakes. The pressure, of course, is not very strong, but the volume of water is rather considerable. If you wish, you can turn on the pump through the speed control, thereby controlling the flow of water. By this principle, you can make a small fountain and so on. On this project is over, I hope you liked the homemade. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!