In this article, the author of the YouTube channel “Folk Craft” will tell you how he made a mold for casting lead sinkers inhome conditions.

Homemade is very simple to manufacture, and it does not require complex machines.

Materials

- 12 mm thick aluminum plate

- wing screws

- steel bar

- Bolts.

Instruments, used by the author.

- Bulgarian

—

—

- Drills, pliers, wire cutters

— .

Manufacturing process.

To begin with, the author cut several blanks from an aluminum plate 12 mm thick. Four rods and two plates. Marked and drilled screw holes on the ends.

I cut a thread in the hole of the main plates.

Then he countersinked the hole so that the screws tightened into the sweat.

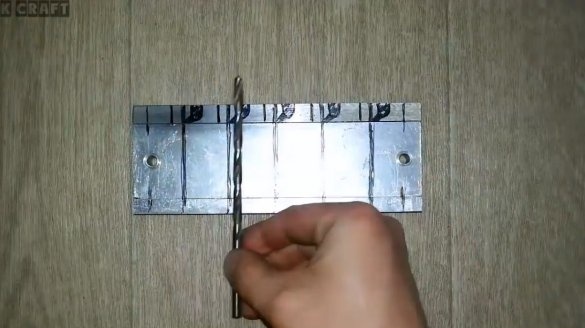

Then he drilled holes in the main plates, through them they will be attached to each other.

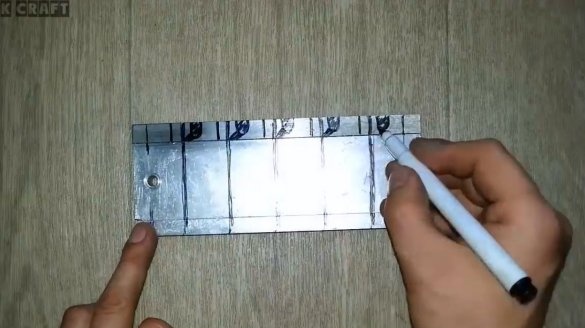

Now marked the future sprues, and injection cavities.

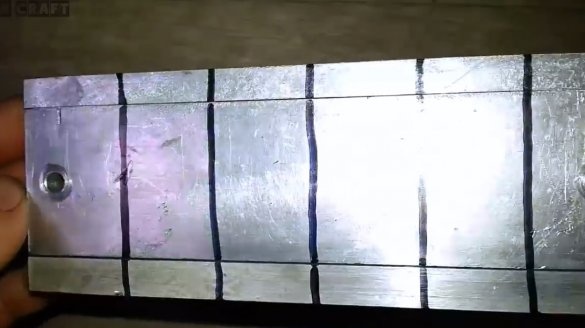

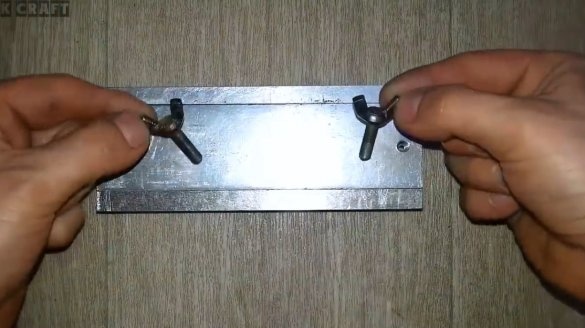

I cut the thread in the second plate and connected them with the wing screw.

Having connected the upper and lower plates together, he drilled holes for pins with a diameter of 6 mm.

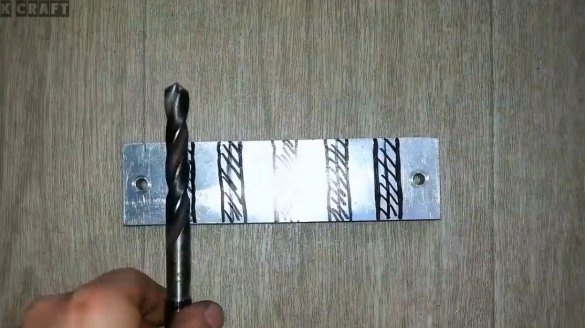

Under the sprue itself, I drilled a hole with a diameter of 10 mm.

Now he pulled together the main plates, and drilled injection cavities with a diameter of 12 mm.

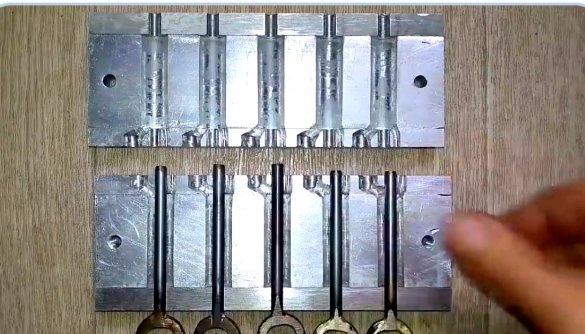

Now almost everything is ready for assembly.

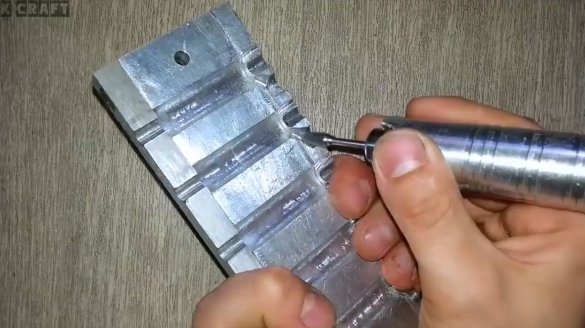

It remains only to drill an injection channel with an engraving machine, and install the pins. In order to make them easy to remove, it is worth lubricating with laundry soap.

The author recommends pouring lead into a well-heated form.

After the metal has hardened, you must first remove the pins from the mold.

Next, just remove the finished weights, and bite the sprues.

Dimensions of finished products 45 mm X 12 mm and weight 47 grams.

The author also made another mold for larger weights.

The circuit is exactly the same, but the pins are much larger and they are made of titanium.

After pouring, they need to be put in order.

To remove the pin from the tube, the workpiece must be lightly tapped with a hammer or mallet.

The weight of the sinker remains the same, but the weight and diameter are already greater.

Thanks to the author for the simple but useful device for casting lead!

All good mood, good luck, and interesting ideas!

Author video can be found here.