Hello to all fans of craftsmen, today we will consider how to build a drilling machine from old parts. As a basis, the author used an old manual drilling machine. The machine is equipped with a flywheel, which accumulates kinetic energy, due to which the machine and drills. The author decided to install the old motor from the washing machine on the machine, and its power was enough for the machine to work. Also, the drilling machine is equipped with an interesting lift in the form of a car jack, which raises the working platform with a fixed part. Of course, the machine has not weak backlash and beats, but for everyday tasks homemade quite useful. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- engine from the old washer;

- manual drilling machine;

- car jack;

- corner for the base;

- pipes;

- fittings;

- sheet metal;

- bolts and nuts;

- Belting;

- paint, grease.

Tool List:

- ;

- ;

- drill;

- screwdriver;

- tape measure, marker.

Homemade manufacturing process:

Step one. Drill preparation

To begin, we will analyze the old hand drill, we will need to replace the grease. We also clean the case of the device from rust and dirt, but it is better to do this before disassembling. To clean the parts, the author used a screwdriver with a wire nozzle. This drilling machine has a very simple principle of operation, it has a flywheel that accumulates kinetic energy, as a result, you need very little force for the machine to drill. This is what makes it possible to install a small motor from the washing machine on the machine.

Step Two Base assembly

We weld the base for a drilling machine, for this the author used a corner, a rectangular frame was welded from it. A piece of pipe is vertically welded to the frame at a right angle, there are cuts and nuts welded in the pipe, this part works like a clamp.A stand is inserted into the clamp in the form of a piece of pipe, on which the drilling unit is located.

Step Three Cartridge

A modern drill chuck must be installed on the shaft of the drilling machine. The author managed to do this using a special adapter.

Step Four Drilling site

For a drilling site, we are looking for a piece of iron thicker and drill a hole where the drill will go. According to the author’s idea, the platform will have to rise in order to carry out this task, it was decided to use a car jack. The jack itself is installed on the bed, and to the other part we fasten the drilling platform.

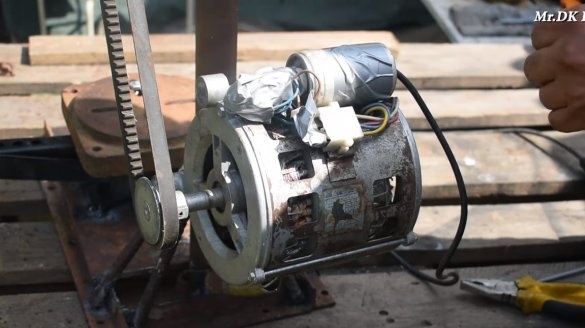

Step Five Engine installation

Instead of a handle on the drill, we install a pulley, the author’s drive turned out to be direct, but it is better to experiment with the gear ratio. The engine will be mounted on one axis, under this axis we are looking for a suitable iron pipe, the pipe is welded to the bed. Now you can install and tighten the belt, the belt is pulled under the engine's own weight. After that, the motor can be turned on and see how everything works.

Step Six Painting and testing

All iron parts of the machine are better to be painted for protection against rust and simplicity of cleaning. After that, the machine can be assembled and tested. As an experiment, the author drills a rather thick board, the machine copes with the task. Of course, during beating, not weak beats are visible, but all these points can be further developed.

On this project is over, I hope you liked the homemade. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!