Some of you may have had to work with drywall. Drywall factory edges are slightly thinner than the bulk of the sheet. This is done to reduce puttying. But if the sheet is cut according to your size, then the joint of two sheets will require more work.

In this article, the author of the Kucher Szechet YouTube channel will tell you how to make a simple milling cutter for processing the edges of drywall.

Materials

- sheet plywood

- Wood screws

- PVA glue

- Bolts, bushings.

Instruments, used by the author.

—

- Concrete disc

—

—

—

—

— .

Manufacturing process.

First of all, the master removes the protective cover from the grinder.

Then unscrews the screws of the gearbox.

Then he marks the required hole on a piece of plywood, and drills it with a step drill.

Now you need to drill holes for the bolts, and countersink them.

Instead of regular bolts, the master took elongated of the same diameter. Made linings from the bushings, and screwed the base of the nozzle.

The wizard set the disc on concrete.

Now he cuts the lid for the future box.

Marked the hole for the dust extraction sleeve, and screwed it.

Now the author has collected the main part of the box.

It remains to screw the front cover.

Using a crown, he cut out a disk, screwed it to the top of the base.

Now you can screw the handle from the grinder into it.

Almost everything is ready, you can connect the hose of the vacuum cleaner.

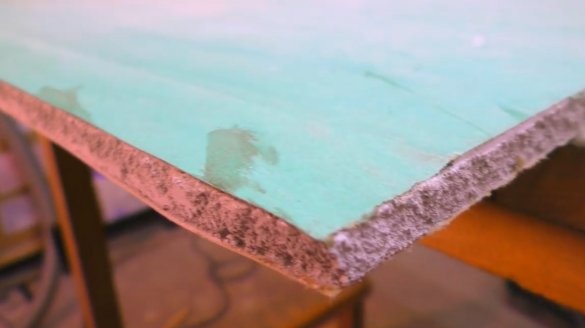

Putting a sheet of drywall on a workbench, it processes the end face with a milling cutter.

The milling cutter cut a thin layer of gypsum, leaving the paper intact. It needs to be glued in its place. After the glue has dried, you can install the sheet. In such a simple way it will be possible to save on puttying.

Thanks to the author for the simple but useful device for processing drywall ends!

All good mood, good luck, and interesting ideas!

Author video can be found here.