I welcome all fans to craft, today we will consider how to make an electric hacksaw based on a grinder. Homemade easy to assemble and does not require complex machines for manufacturing. The tool works perfectly, the author easily saws hacks, boards and even logs with a hacksaw. The machine works due to the fact that the rotational movements of the shaft of the grinder turn into reciprocating movements of the hacksaw. The design of the grinder does not change, the homemade made is just a nozzle for the grinder. If you are interested in such a project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- old hacksaw;

- a piece of iron pipe;

- sheet metal;

- bolts and nuts;

- one bearing;

- paint for metal.

Tool List:

- drill;

- files;

- welding machine;

- drilling machine;

- grinder;

- vernier caliper;

- marker, tape measure.

Homemade manufacturing process:

Step one. Hacksaw

First of all, we need a hacksaw, an old tool will do, but it will need to be sharpened. We remove the handle from the hacksaw, it will not be needed. If desired, the hacksaw blade can be significantly shortened, since its stroke will be small.

Step Two Eccentric

Homemade works thanks to the eccentric, which is mounted on the shaft of the grinder. As a part, we need a ball bearing and a piece of a bolt, from which the author has machined a suitable pin. We install the bearing on the shaft so that it is displaced, securely fasten it with nuts and washers. As a result, when such a bearing rotates, it will move the hacksaw blade back and forth.

Step Three Clamp

Next, we have to make a clamp, it will also act as the basis on which all nodes will be fixed. Here we need a piece of iron pipe, its inner diameter should coincide with that part of the grinder to which the shield is attached. Cut a piece of the desired length and make an incision in a circle of the workpiece. Next, a cut is made across and along the cut two nuts are welded, one with a thread, the other without.As a result, we get an excellent clamp that can be pulled on a grinder with a screw or bolt.

Step Four Hacksaw blade

We prepare the hacksaw tightly, we need to drill a hole in it of such a diameter so that a bearing mounted on the shaft of the grinder fits in it. The author drilled a hole on a drilling machine with a step drill.

Next, the hole must be oval so that the canvas moves in only one direction. Here files and a drill will come to our aid.

Step Five Frame

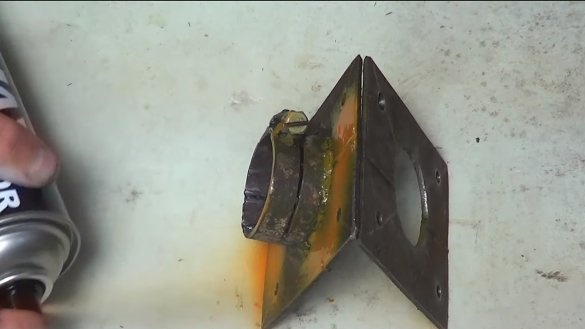

Almost all the details are ready, it remains to make a frame, here we need sheet metal. We cut two plates and drill into one hole along the diameter of the clamp, weld this part to the clamp, this will be the basis.

Also in both plates you need to drill holes for the bolts that will hold the plates together. Bolts need to be welded to the base.

At the end, it remains to finalize the hacksaw blade, drill 4 holes in it in those places where the connecting bolts are. Holes need to be bored with a file to an oval shape. As a result, the bolts will serve as guides that will hold the hacksaw blade.

Step Six Painting and assembly

We paint all the details so that the homemade product does not rust and looks good. Well, then everything can be assembled, we establish the base and the clown, and then it remains to put the hacksaw blade and the upper part of the frame. The homemade product is ready, you can experience it, but do not forget to grease everything well! The tool cuts the bars, and even the log. Of course, the performance of the saw is not very high, since the hacksaw's travel is small.

In general, the homemade product deserves attention, since everything is done quite simply. This is the end of the project, I hope you liked it, and you found new ideas for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!