Good day to all. Today the hero of our article, he is also the author of the channel “Men's Craft” Dmitry will show us how he did not difficult, but at the same time useful device for angle grinders. Using this homemade cutting off exactly metal is much simpler and easier, and by the way, you can cut not only metal, but also any other material, it’s enough to install a suitable cutting wheel on the angle grinder.

TOOLS and MATERIALS:

Marker;

Square;

Angle grinder;

Circles: cutting and petal;

Welding machine;

Electrodes

Electric drill;

Drill;

Sheet metal;

Vise

Hammer;

Hairpin, approximately M-10;

Nuts M-10;

Magnetic square;

Bolts and washers for attaching homemade products to angle grinders;

File;

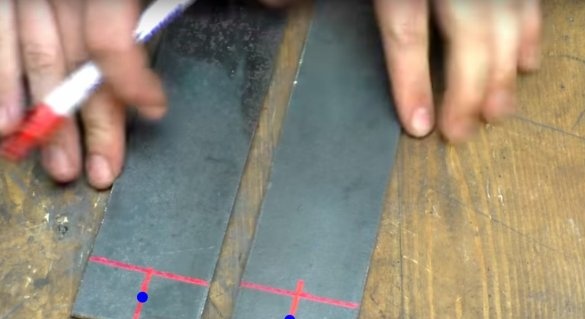

At first, the author cut off two strips of the same size from sheet metal.

Then he made markings on them. Like in the photo.

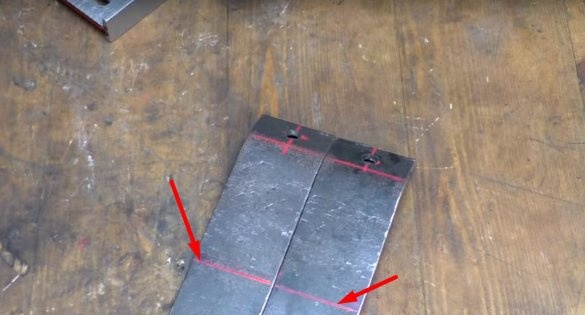

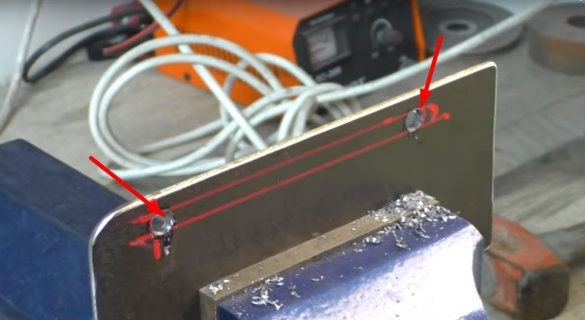

Then he made holes in the marked place. First with a small drill.

And after the big one.

Like this.

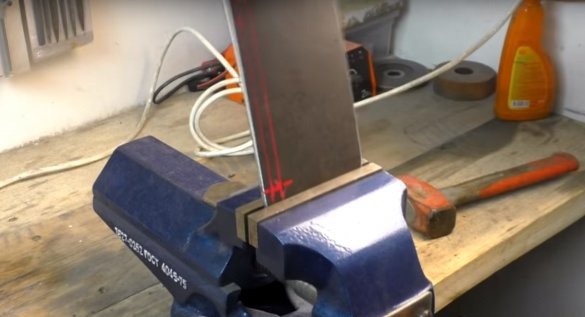

Further, the author clamped these blanks in a vice and, using a hammer, slightly bent them.

Like that.

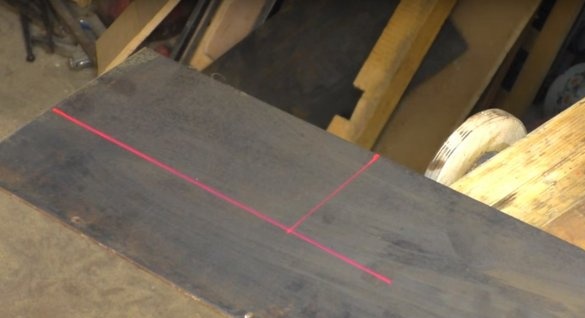

Then markup again.

And removing the excess.

Next, the author will weld a stud to one of the blanks.

After it will process the weld.

Such a detail turned out.

The master will install this detail on the angle grinder and fix it with a bolt.

On the second side of the angle grinder, the author will install the second part and fix it with a bolt.

After the second part, also weld to the stud.

And will process the seam.

Then leaving not large edges of the hairpin, cut off the excess.

Such a detail.

After that, on each edge of the stud, the master will install one nut. And set this part aside.

And he will begin to manufacture another part, his homemade product. To do this, he will cut a piece from sheet metal.

Rounds two edges on it.

Make markup as shown in the photo.

Further, the edge will slightly bend with rounded corners.

Like this.

After in the marked places will make a couple of holes.

And then remove the excess.

Handles the cut with a file.

The second part is ready (Sole).

Then, the previously made part, the master will install on the sole.

And holding the parts with a magnetic square.

Welded nuts to the sole.

Also by the author, another nut was welded in this place for attaching an additional handle.

Here is the finished device.

The master installed homemade on angle grinder.

And fixed it with bolts.

Like this.

After installing an additional handle.

And proceeded to the test.

Result on metal.

On plywood.

The sole of the device moves freely, for the author it is not important. (But the master says that if you wish, it can be fixed or even made so that the depth of cut can be adjusted.) Such a useful homemade work was obtained today by our hero. Thank you very much for that.

And that’s all for me. Thank you all and see you soon!