The main drawback of many workshops is the lack of space. The master decided to put the workshop in order a bit and install the drilling and trimming machines in a row with the work table.

Tools and materials:

-Fasteners;

-Boards;

-Plywood;

-A circular saw;

-Miter saw;

-Drilling machine;

-Grinder;

-A screwdriver;

-Conductor;

- Joiner's glue;

-Clips;

Step One: Wireframe

First, the master performs the sawing of the material and assembles the table frame.

Step Two: Countertop

From the plywood sheet, the master cuts the countertop. Drill mounting holes.

Step Three: Install a Drilling Machine

The supporting part of the drilling machine will be installed under the countertop, and the work table above it. The master makes an additional reinforced shelf. A cutout is made in the countertop.

Step Four: Dust Cap

So that the dust, during work, does not fly apart, the master makes a dust cap over the saw.

Built in socket for connecting hoses of a vacuum cleaner.

Screws the front end.

Step Five: Miter Saw

Secures the miter saw.

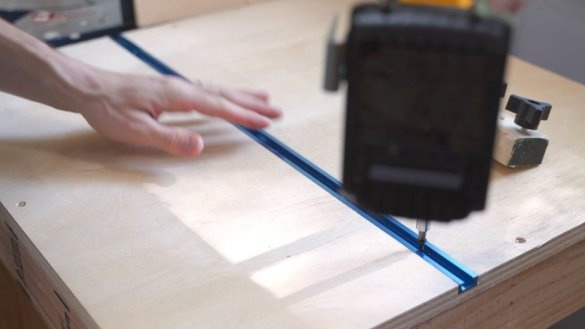

Step six: guide and various little things

Cuts a groove and secures the guide.

Glues a measuring tape.

Makes clamps.

Sets shelves.

All is ready.

The whole process of making the table can be seen in the video.