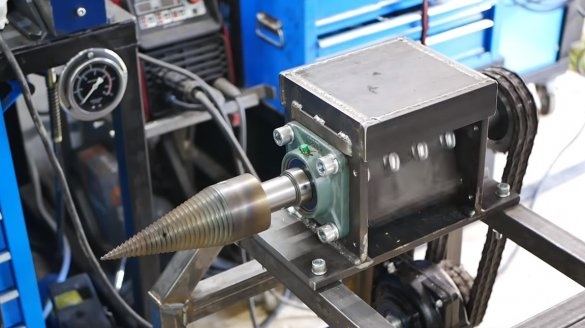

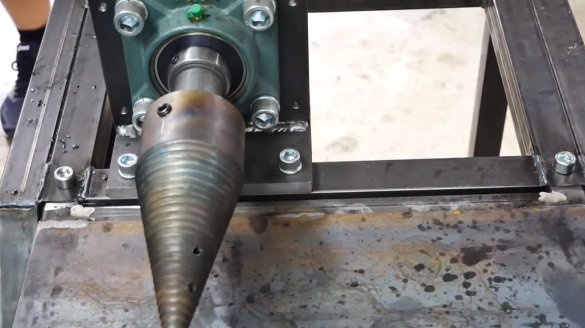

Hello to all lovers of craftsmanship, summer is coming to an end, which means that it is time to stock up on firewood to spend the winter in warmth and comfort. And in order to simplify such hard work, the author decided to assemble a machine for chopping firewood. For splitting stumps of large diameter in the car, a classic "carrot" is provided, this is a shaft in the form of a cone with a thread. But the design flaw is that each stump has to be raised for splitting onto the table. However, only problematic hemp with knots can be split with a machine.

Also in the car there is a very useful unit for processing branches, which are usually emitted. The machine threshes branches into small parts, which are very convenient to heat the furnace. As a result, nothing disappears and the work is simplified. If you are interested in the idea of making such a machine, I propose to consider the project in more detail!

Materials and tools used by the author:

Material List:

- profile pipes;

- wheels;

- round timber;

- steel plates;

- sheet steel, screws, bearings in housings (for crushing unit);

- gear motor 2.2 kW;

- chain transmission;

- "carrot"

- sheet steel for shields and sleeves;

- paint for metal;

- cable, switch.

Tool List:

- tape cutting machine;

- lathe;

- drilling machine;

- welding machine;

- LSHM;

- wrenches, screwdrivers, etc .;

- vernier caliper, tape measure, marker.

Manufacturing process homemade:

Step one. Frame

We assemble the frame for the machine, as a material the author uses a square profile pipe. Everything is cut in accordance with the drawings and welded. Of course, the design is quite complicated, so you can not do without magnetic squares and other tools. It is convenient to cut such pipes with a tape cutting machine, but you can also handle the grinder.

Step Two Castors and legs

For convenient movement of the machine you will need two wheels for garden carts. As an axis, the author welded a round timber to the frame and put the wheels on. On the other two legs we weld the supports from sheet iron, the author also cut out the supports himself.

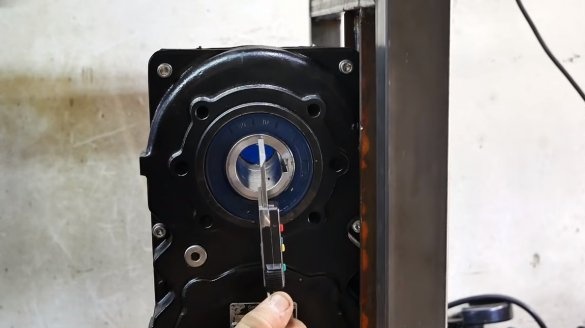

Step Three Crushing unit

The author made the crushing node in advance, he has a separate video on this topic. For the knives of the crushing unit, you need strong steel, which it is desirable to harden. Knives need to be made removable so that they can be sharpened at any time. The frame of the unit itself must be very strong, since it experiences considerable loads.

The crushing unit is welded to a thick steel plate, which is attached to the main frame with screws.

A “carrot” is also installed on the shaft of the crushing unit.

Step Four Engine installation

Next, we install the engine on the frame, but first we make the fasteners. Here we need a thick steel plate, we need to cut through the slotted holes in it, which will allow us to tighten the chain or belt drive. The author cut through the cracks with a plasma cutter and a drilling machine.

The engine turned out to be quite heavy, but for the author it was not a problem, since earlier he had made an excellent crane.

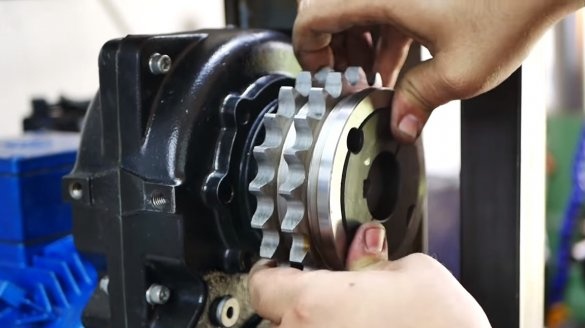

Step Five Drive unit

The drive to the crushing unit with a carrot is carried out using a chain transmission, and so that everything works for a long time and does not break, two chains are used. For the engine gearbox, the author had to grind an axis on a lathe. We fasten the sprockets, install and pull the chains. You can also install a “carrot”, a turner can make it for you.

Step Six The finishing touches of the assembly

At the end, opposite the “carrot” we need to make a countertop, it should be folded so as not to interfere with transportation. We weld it from profile pipes and sheet steel, and the hinges can be used for gates.

A wedge should be welded to the countertop, which will split the log.

It is also extremely important to make a receiving and outgoing sleeve so that nothing is sucked into the unit by an outsider and that chips do not fly. We weld a sheet steel structure. Hooks can be welded onto the outgoing sleeve so that a bag can be hung into which crushed wood will fall.

Be sure to make a protective shield over the chain drive, otherwise using the machine will be very dangerous.

Do not forget to put in an easily accessible place and emergency switch. After painting, the machine is ready and can be tested.

Seventh step. Test

The machine turned out to be powerful, she swallows the branches herself and spits out ready-made firewood into the bag. The maximum diameter of the branch, which can easily withstand the crushing unit, is 4 cm.

"Carrot" also works great, it easily pricks such stumps that would have to be chopped with an ax for a very long time.

The project is over, the car turned out successful, powerful and reliable. I hope you enjoyed your homemade work and found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!