Concrete the furniture you won’t surprise anyone. It is widely used in the design of interiors of modern apartments and country houses. And even more so, a concrete chair will be appropriate in any garden or courtyard.

Concrete furniture is characterized by high performance. It is durable and lasts for decades. The lack of comfort is easily compensated by the use of textile elements such as pillows or mattresses, as well as natural wood.

In this master class, you will learn how to make a concrete chair in home conditions and make sure that anyone can do it.

So, if you have not yet acquired furniture made of sand and cement, you will need:

Materials:

- ready-mixed concrete with fine aggregate or cement, sand and aggregate like gravel;

- material for formwork with a smooth surface. The author used wood chipboard MDF;

- hot glue for fixing the formwork;

- silicone for sealing joints;

- adhesive for expanded polystyrene;

- cardboard for the manufacture of patterns;

- polystyrene foam for the inner part of the formwork;

- fittings and knitting wire for connection;

- matte varnish for concrete.

Instruments:

- jigsaw;

- a construction mixer or drill with a nozzle for mixing the mortar;

- Bulgarian and cutting wheel for metal;

- construction tape, ruler, square;

- a gun with hot glue;

- spatula, trowel;

- building capacity of a suitable size;

- nippers;

- protective equipment for working with cement mortar;

- marker.

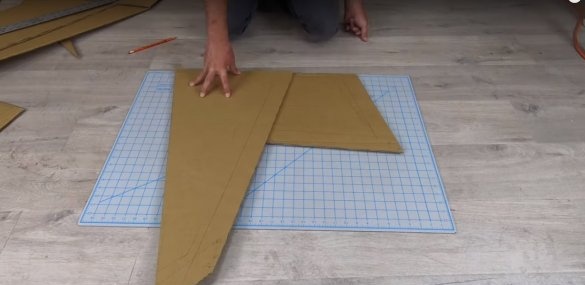

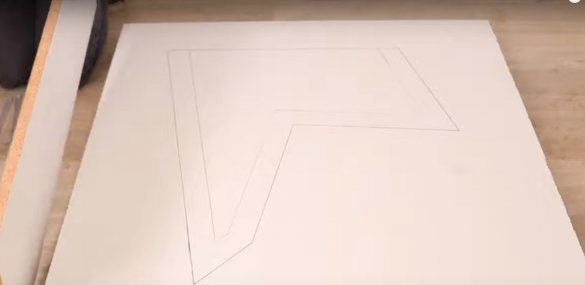

Step one: making patterns

The author used cardboard for making patterns. He made a frontal drawing of a chair - in the form of a future formwork. The patterns consist of two elements, each of which has an inner part and an outer contour.

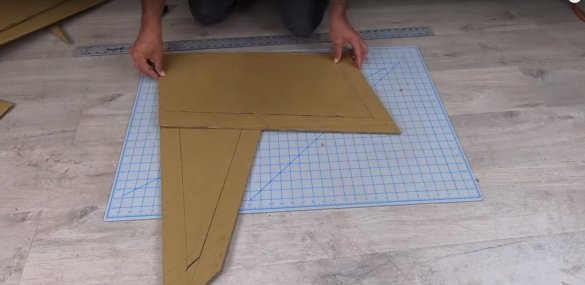

Step Two: MDF Markup

MDF is the best suited for this kind of project. Firstly, it is an affordable and inexpensive material, and secondly, it has a smooth side, to which the finished concrete product practically does not stick.

Mark the formwork parts, as well as the corners, to fix it on a plane.You will also need the plane itself, on which you install the formwork elements.

Cut out the formwork using a jigsaw or manual circular.

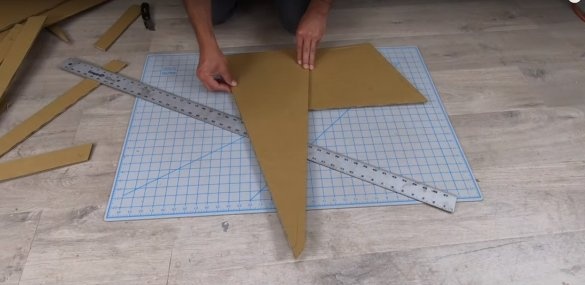

Step three: marking the inside of the formwork

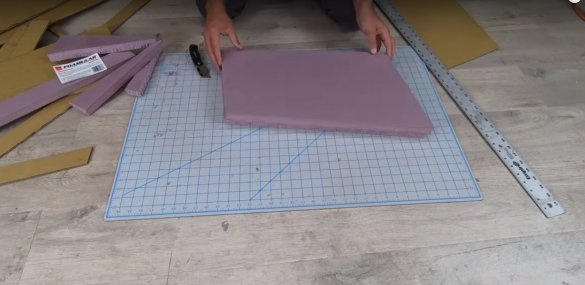

For the manufacture of the central part of the formwork, taking into account its height, a multilayer material with a dense surface and optimal cost is required. Expanded polystyrene, a sheet insulation, with which it is very easy to work with, has these criteria.

Mark the parts made of polystyrene foam. The author collects the inner part with the dressing of each row (see photo).

Note that the details should clearly repeat the shape of each other, given that the interior of the finished chair according to the author’s idea is not subject to editing and grinding, but should initially have a flat surface without flaws.

Cut the marked parts under the ruler with a sharp clerical knife.

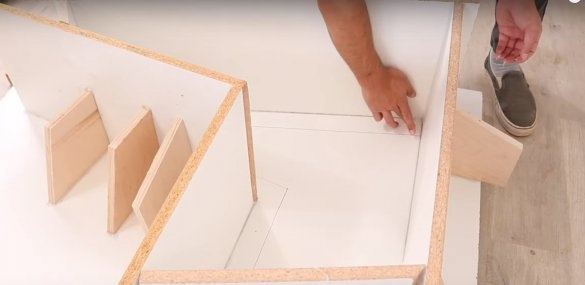

Step Four: Formwork Assembly

On the MDF sheet, draw the outline of the formwork and proceed with its assembly. Large parts are held in place by the corners of MDF on hot glue.

All external slots should be filled with hot glue. The joints of the formwork elements inside, coat with silicone, simply spreading it with your finger along the seam.

Assemble the details of the polystyrene foam formwork with the dressing of each row using glue. Try to stack them as evenly as possible, since any curvature will be printed on the inner plane of the chair and will be noticeable. Place a load on top and wait for the glue to dry completely.

Step Five: Making Metal Inserts for Reinforcement

From the reinforcement with a diameter of 10 mm, the author made two U-shaped parts for reinforcing the chair. He collected them using ordinary knitting wire. The dimensions of the inserts are arbitrary with a gap between the walls of the formwork.

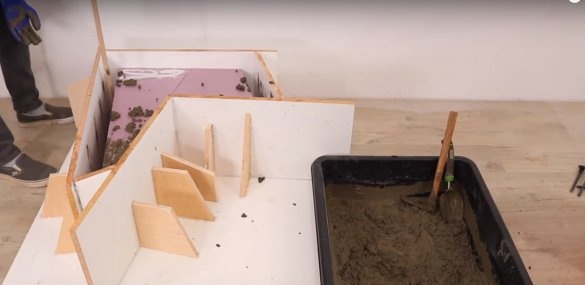

Step Six: Cement Mortar and Formwork

The author used a ready-made concrete mixture based on cement of grade 5000. It can be replaced with a classic cement mortar made from cement, sand and fine aggregate like gravel.

You should also add a special plasticizer. In the absence of branded products, the role of plasticizer is easily performed by a dishwashing detergent added to water when mixing the solution.

If you want to get a white product, use white cement or a special mineral dye.

Knead a solution of medium density and start filling out the form. Compact each new layer with a rammer. The author uses a wooden rail.

Before reaching 5 cm to the crowns of the formwork, lay the reinforcing blanks with the spikes down. Fill the formwork to the edges, carefully level with a spatula.

Step Seven: Final

Leave the solution to solidify at a temperature of no more than 25 ° C. Mortar should not set too quickly. If the room is hot or you are working in the sun, cover the surface of the solution with a cloth and moisturize it regularly.

After a couple of days, the formwork can be removed. The solution is still malleable for making corrections, so at this point you can correct the flaws or sand some areas.

A couple of weeks will pass, during which concrete will gain the necessary fortress for transportation and operation.

If desired, the concrete surface can be coated with a special matte varnish.