Surely many of you love antiques. Especially those that had to be recreated from scratch.

In this article, the creator of the Measured Workshop YouTube channel tells you how he recreated the design of an old mechanical gong for a boxing ring. Now this design can be used as a doorbell.

Such a call will make a very loud single sound if you pull the rope.

The author’s father purchased a non-working electromechanical gong at a flea market. The diameter of his plate is 10 inches. She will be the main part of this homemade product.

Materials

- Old boxing gong

- Stainless steel plate

- Oak log

- Springs

- Washers, nuts

- Studs, bolts

- Round screw

- Paint remover

- Emery paper 80 - 240 grit

- Rags.

Instruments, used by the author.

—

—

—

- Cutting and cleaning wheels

- Thicknesser, circular saw

- Drilling machine, drills for metal and wood

—

- Belt sander

- Vise, core, hammer, pliers, wrench, metal brush

- Ruler, marker.

Manufacturing process.

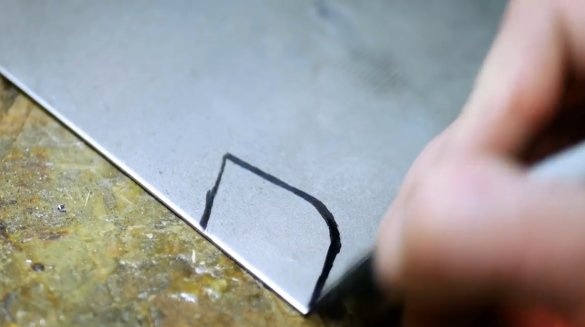

First of all, the author proceeds to the manufacture of a shock foot. He marked the steel plate, and made the necessary cuts.

These two petals must be reduced in thickness.

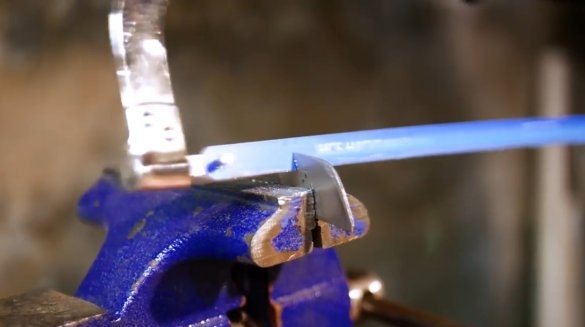

The master fixes the base of the foot in a vice, and bends the petals at an angle of 90 degrees. It is on them that the plate will hold.

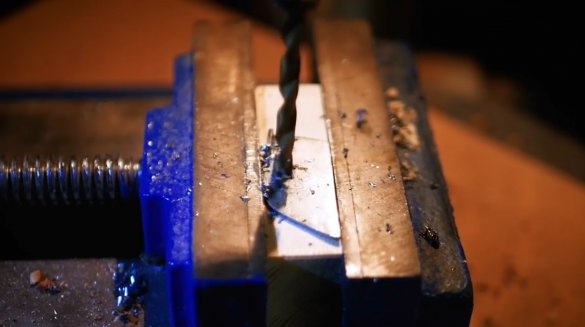

A hole for the axis is drilled in the paws. And at the base - holes for fastening the striker, and the tension spring.

The corners of the legs, and the edge of the plate are rounded, sharp edges are ground on a tape machine.

The plate is fixed in a vice, and bends almost in the middle at an angle of about 15 degrees.

Here is a blank of the first part.

Now you need to make the trigger itself, it is also the platoon. The workpiece is roughly cut by a grinder.

The disk is replaced with a flap-clean, and defects are removed. More precise processing is done on a tape machine.

Then it is marked with a core, and holes for a lace, a dog and an axis are drilled.

A dog is cut and processed, which will cock the plate.

A hacksaw is made in it to cut, then one of its edges is bent.

In the dog you need to drill two holes for attachment to the hook and spring.

Now all the workpieces are sanded manually with sandpaper. The master stops at the 240th grit.

Next, you need to connect the dog with a hook. For this, the master will use a rivet.

In order to leave a small gap, the master inserts between the dog and the hook measuring probe 0.15 mm thick from the kit. Then rivets the riveting gun.

As a result, we got such a moving dog.

It came to the gong. The author parses it, throws out only the electromagnet, and leaves the bolt and washers.

The condition of the plate is completely unpresentable. Lubricates it with a liquid to remove paint, and after a few minutes cleans it with a knife, wire brush, and removes with a rag. The back side is cleaned of rust with sandpaper.

Finishing the outer surface with an orbital machine, and manually.

The main parts of the mechanism are ready.

Now you need to make a base. For this, the master chose a piece of oak massif. Trimmed in length, and processed in the thicknesser.

In the machined workpiece, he drills the necessary holes for two locking bolts, and two axles from the studs.

Saturates the surface of the base with linseed oil.

In addition to the finished parts, such elements will also be required.

The impregnation has dried, and the master screws in the locking bolts and studs.

Putting a plastic washer, puts a trigger with a dog on the axis.

The impact plate will be located a little higher, the author had to pick up a few washers for the lining.

Now, without fixing the plate, it checks the operation of the mechanism.

He fastens the hammer to the plate, for this he picked up a small wooden furniture handle.

In the center of the base, a self-tapping screw with an eye is screwed. Then a spring clings to the plate, is pulled by pliers, and is fixed by the second end to it.

The second spring clings to the hole in the dog, and to the eye of the screw.

When the striker moved, the master discovered that the springs were making a ringing sound. Therefore, he planted a piece of velvet under them, and secured it with a furniture stapler. Now the mechanism works as it should!

It remains to make a lining for installing the bell. Cutting it to the desired size, the author drilled four through holes for fixing screws, and one for the plate fixing bolt.

A furniture nut is hammered into this hole, and the stand is screwed to the base with self-tapping screws.

All original parts are assembled in reverse order. First, the lining, then the bell, branded washer, and tightened with a screw.

Well, the mechanism works fine, and to adjust the sound volume, you can simply change the size of the striker, or put washers under it.

So the work of the mechanism looks above.

Everything is ready, you can mount it on the wall, and put the lace out the door through the silicone tube.

Of course, you can make such a call from a small bell.

Thanks to the author for the work done to restore the old gong!

All good mood, good luck, and interesting ideas!

Author video can be found here.