for the manufacture of racks: timber 45x90 and 50x50, plywood 10 mm thick, furniture ball guides 30 cm long, tension spring.

Step-by-step instructions on how to make a stand for a drill do it yourself

1. The manufacture of the machine frame

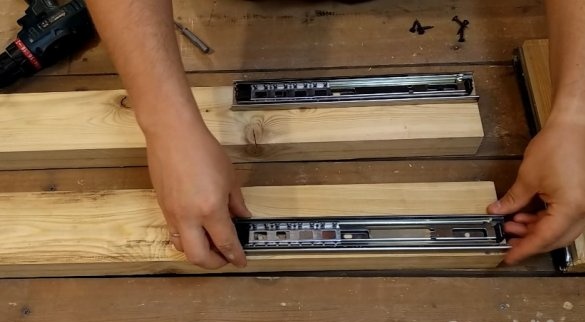

Attach the guide to the bar 45x90x300 mm, mark with a pencil the places for drilling holes. Turn the segment 180 degrees, repeat. Drill two holes on each side.

Try on guides, check, connect parts with self-tapping screws. Repeat for the other side. After we have disconnected the parts of the rails, they must be additionally secured with a third self-tapping screw.

Got the base of the drilling carriage.

We try on and mount the carriage to two pieces of timber with a length of 700 mm.

We try the design in motion.

Try on the lower beam cross member 50x50 mm (it is needed to increase the rigidity of the structure), apply a plywood base, draw a pencil around the connection with the ends of the racks.

Mark future holes for fasteners. Drill holes at the intersection points of the verticals and horizontals.

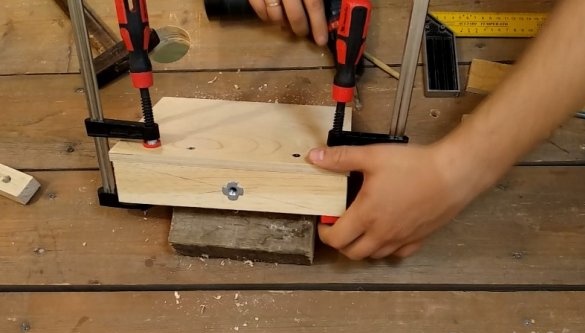

Attach a cross member to the plywood base, secure with clamps. In the designated places, drill holes and fasten with wood screws. It turned out the basis.

Mount the rack on the base.

Reinforce the bed at the top with a plywood strip for rigidity. Check for smooth running.

The frame is finished.

2. Manufacture of a drill holder

I don’t know where the handle from the drill (not native) was lying around, I decided to use it to fix the drill. Let's continue.

Put the handle on a piece of board 20x90 mm 30 cm long.

Circle the outer contour and hole with a pencil.Use a jigsaw to cut the contour and the seat.

Attach the handle to the board with self-tapping screws.

Mark and drill holes in the bottom of the board.

Attach the board to the central carriage, check the ease of movement.

On the rear side of the structure, drill holes for the hooks for the springs, assemble.

To increase the rigidity of the structure by the force of its bar 50x50x90 mm. Attach a segment to the drill holder, strengthen the structure from above and below with self-tapping screws.

Use a clamp if necessary. Check the vertical axis of the drill stand.

3. Production of height-adjustable table

Make a wing nut from a piece of a slat - draw diagonals, find the center, drill. Install the M8 mortise nut, drive inward with a hammer.

Also, using a mortise nut and an M8 hairpin, we make the base of an adjustable table.

Tighten the connection with a wrench.

From the remnants of plywood, make the back plate, put it in place, connect it.

Mark the places where the stand adjoins the walls. Make stops, fasten with screws.

Secure the table to the counter.

4. Lever

The lever is made of battens and fasteners, which was at hand.

If there are scraps of timber and sandpaper, you can make a device for grinding (homemade grinding drum).

The detailed manufacturing process of the lever and the drilling machine as a whole can be seen in the video:

Now are you convinced that making a stand for a drill is not so difficult?