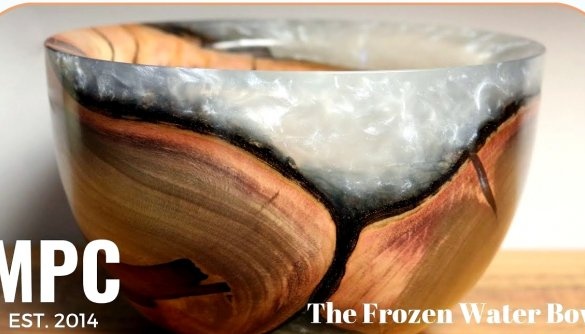

In this article, the author of the YouTube channel “Moonpie Creations” will tell you about his project - a bowl of wood and epoxy.

Materials

- Two-component injection molding epoxy

- Log

- abrasive paste

- Sandpaper

- Impregnation for wood

- Varnish

- Wood screws.

Instruments, used by the author.

- Chainsaw

—

- Pressure chamber

- Lathe

—

—

- Chisels.

Manufacturing process.

He cuts a suitable block with a chainsaw.

Cuts a bark on a band saw

In a measuring cup, knead a portion of epoxy resin, adding the pigment “Pearl Satin” to it.

He places the block on a plastic basin and fills it with the first portion of resin.

Then the author immerses the workpiece in a pressure chamber to squeeze out air bubbles from the composition.

Thus, it comes four times (4 servings of epoxy), each time placing the container in a pressure chamber.

And here is the result. There are no cracks or potholes on the workpiece removed from the plastic mold. All areas are uniformly covered with resin.

The master screws the faceplate to the workpiece, and installs the workpiece in the lathe.

It selects the optimal speed of rotation, starting from 600 with rough turning, and bringing to 800 and, finally, to 1050 revolutions.

First, he removes large defects, then smaller ones.

At high speeds, the extrusion of the outermost shape of the bowl is already in progress.

Now the master covers the workpiece with a layer of Rossini brand grinding primer.

Then there is re-grinding at 240 rpm, which is brought up to 800-hundred.

The material is coated with Yorkshire Grit Turning Abrasive Paste. The paste is carefully rubbed with a piece of cloth. At the end, the author applies a layer of “OB shine juice” to give the surface a shine.

The photo shows how strongly the texture of the material is manifested. The master overlays 6 layers.

The next step, the author will cut out the inner surface of the future bowl. First, a selection is made in the very center with a Forstner drill, then the sides. The whole process took one hour and 10 minutes.

Further, the inner surface is smoothed with a felt disc to smoothness.The fibers were pretty stiff.

The inner surface is also treated with several layers of grinding primer (up to 5-6 layers).

Then with yorkshire grit abrasive paste and finally with a shine layer (varnish?) Of “OB shine juice”. The last tool is applied in 5 layers.

The bottom of the bowl is processed with a semicircular chisel. And polished with a felt nozzle.

The bowl is in front of you! The author gave her the name - Bowl with frozen water.

I thank the author for the interesting idea of making an unusual and beautiful bowl!

All good mood, good luck, and interesting ideas!

Author video can be found here.