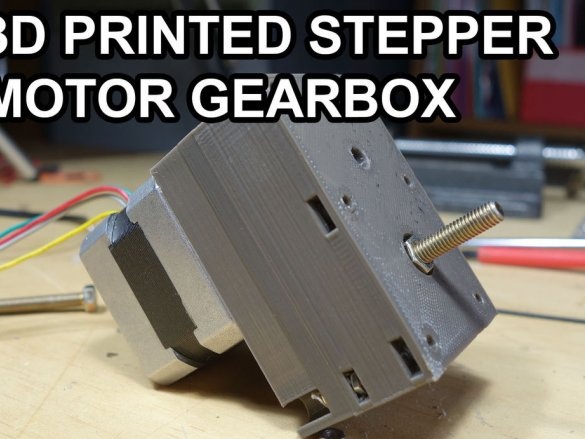

Nema 17 stepper motors are used in many homemade. The master designed and printed a gearbox for the engine on a 3D printer. The gearbox has a gear ratio of 1: 15,625. Those. when the input shaft (motor shaft) is turned 15.625 times, the output shaft makes one revolution.

You can download files for printing gear parts here.

The following details are still needed:

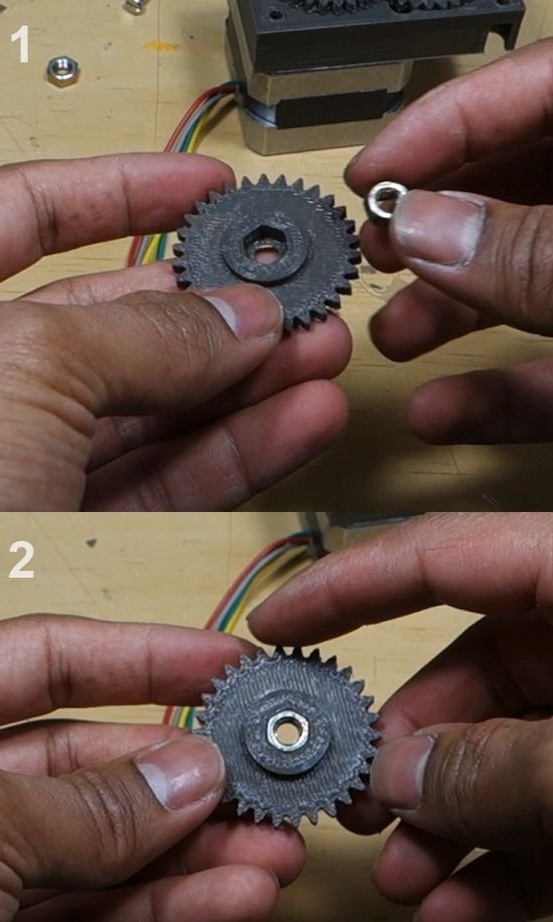

- Bearings MR105-ZZ (5x10x4 mm) - 2 pcs;

- M3 nuts - 7 pcs;

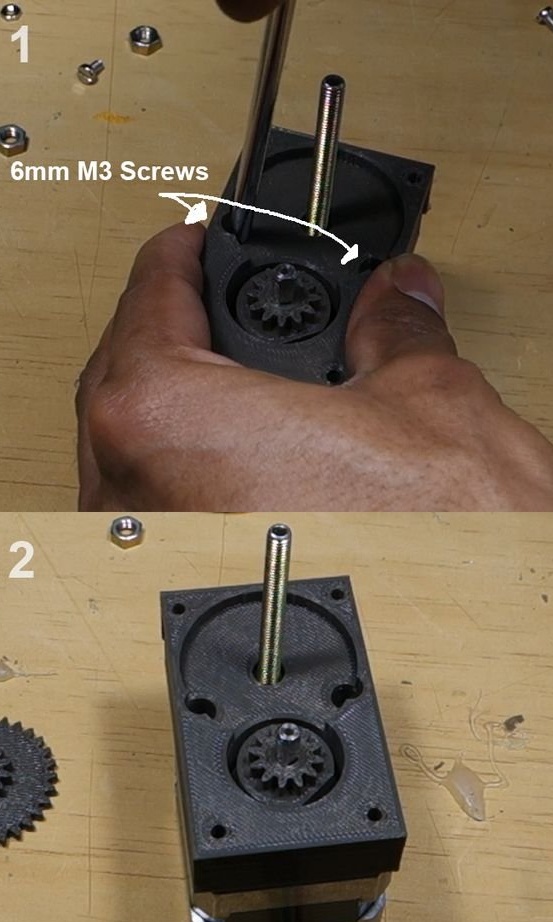

-M3 Screws

6 mm - 2 pcs.

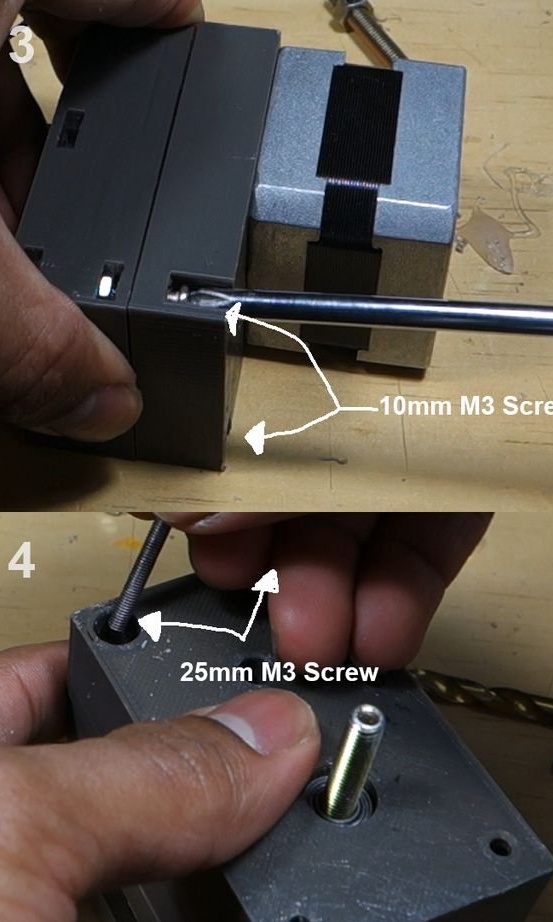

10 mm - 2 pcs.

25 mm - 2 pcs.;

-Bolt M5 50 mm with a hex head;

-M3 screw with internal hexagon;

-M5 nut - 2 pcs.;

-Super glue;

Well, the engine.

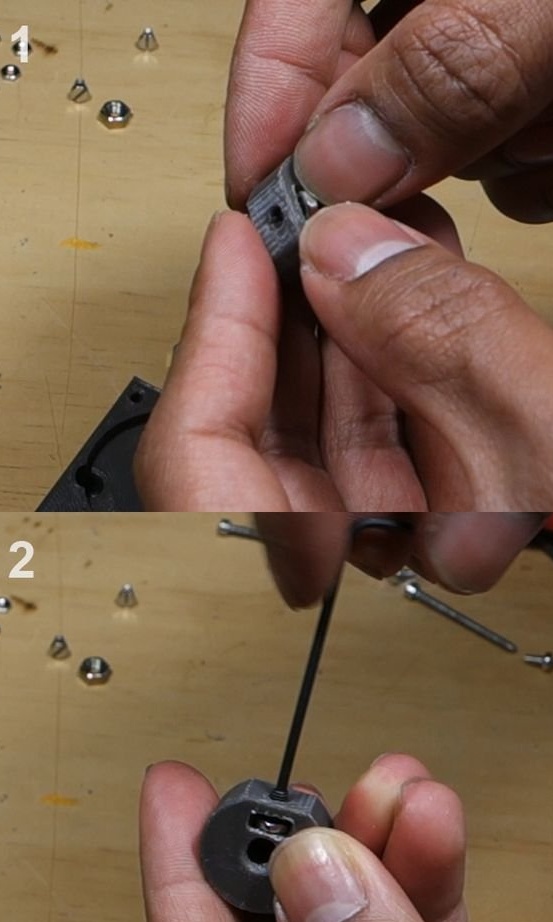

After printing, remove all burrs and drill holes.

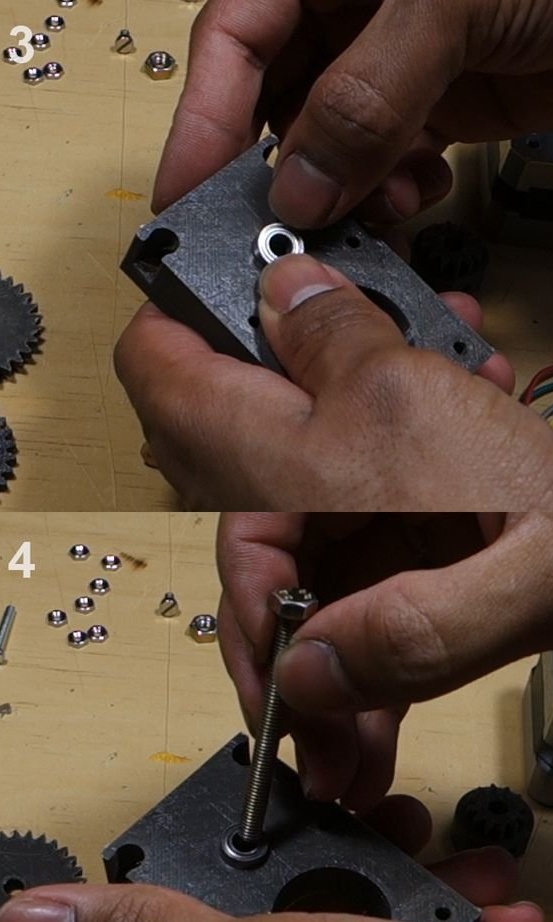

Install the bearing and screw M5.

Mounts the gear on the shaft.

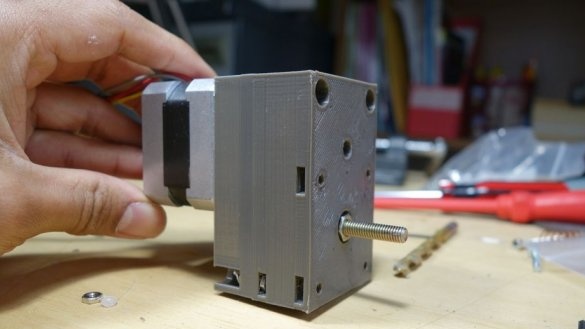

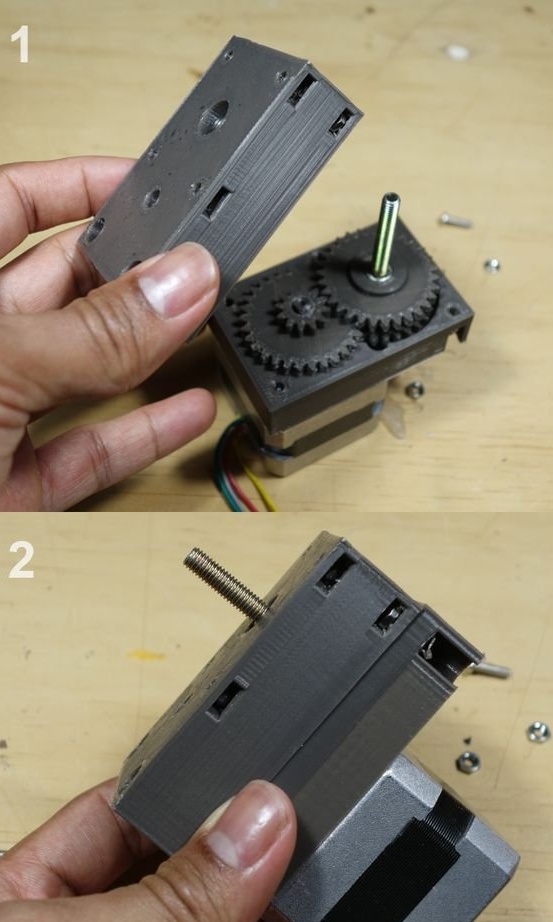

Screws the gear housing to the engine and sets the gears.

Installs the nuts in the grooves.

Installs a second bearing.

Now it remains to screw the top cover.

All is ready.

I hope this article is useful to anyone.