Many masters have a situation where some tool is urgently needed, and it is necessary to make it yourself.

In this article, the author of the YouTube channel “JSK-koubou” will tell you about a quick way to make simple temporary joiner's vise, similar to the vise of Moxon. There were already articles on the site about this subspecies of vise.

For this homemade product, you do not need a complicated power tool, you can do it manually.

Materials

- sheet plywood

- Furniture steel corners

- Screws, washers, nuts M4

- Wood screws

— .

Instruments, used by the author.

- A circular saw

- Hand planer

—

—

- A screwdriver.

Manufacturing process.

First of all, the master glues two M4 nuts to the holes in the steel corners with the help of two-component acrylic glue, and presses them with screws. It is important that the glue does not get into the thread.

After polymerization of glue, connects two corners with the bottom screw. Inserts a clamp in a pair of such corners, and tightens the upper screw. The author uses clamps with a double upper sponge.

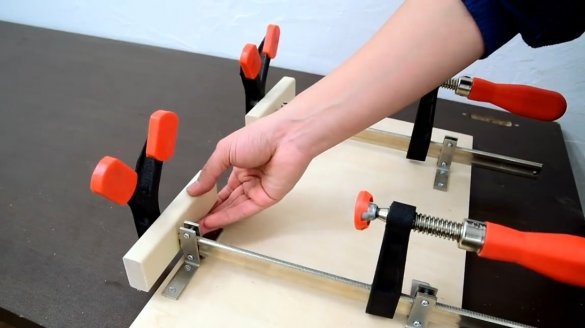

For the exact installation of the clamps, the master clamped an even board in them, and screwed the corners to the plywood base.

But there was one problem. When releasing the clamps, the workpiece may fall on the upper part of the corners, which will cause damage to the surface of the part. To eliminate this drawback, you can put on a corner a piece of insulation or a rubber hose.

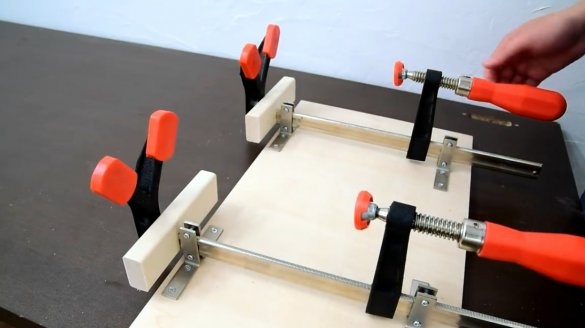

But the master has a small circular saw, and he decides to make two special stands. A cut is made in the board, and the supports are cut off. These cuts can be done with a conventional hacksaw.

Now he sets in place, slightly pushing the clamps forward.

The problem is eliminated, the workpiece falls on wooden supports.

That's all done, you can process the wood with a planer.

You can also cut the workpiece with a saw, its halves will not fall.

To process small parts, or their ends, you can put two boards.

I thank the author for the simple but useful device for the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.