Almost every master is faced with the processes of grinding parts and products, and for this completely different fixtures and devices. These are all kinds of hand holders, grinding machines and machine tools.

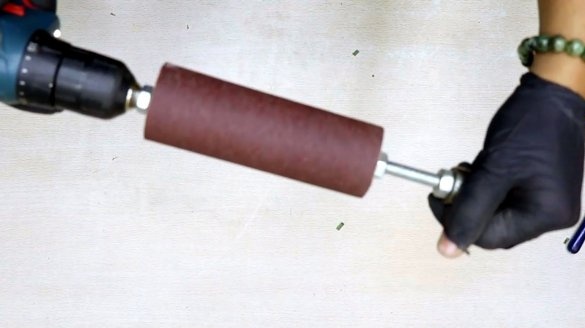

In this article, the author of the Be Creative YouTube channel tells you about a way to make one of them. Namely, a drum nozzle for a screwdriver or drill.

In the manufacture of this homemade product, it is quite possible to do without a drilling machine. No particular accuracy is required.

Materials

- Boards

- Steel stud

- Nuts, washers, bearings

- Sandpaper.

Instruments, used by the author.

- Drilling machine

—

- Drills for wood, countersink

—

—

—

—

- Cutting and cleaning wheels

- Vise.

Manufacturing process.

First of all, the master installs such a crown on a drilling machine.

Several discs are made from a regular board or thick sheet plywood. Their central opening is increasing.

The edges of the holes must be countersinked for a more snug fit between the disks.

The author fixes the workpieces with a geyfer grip, and cuts the M8 thread in the holes.

A nut is screwed onto the stud, the washer is put on, and then the manufactured discs. At the end, the washer is put on again, and the whole structure is pulled together with a nut.

Now the product is fixed in the chuck of the drilling machine, and the surface of the cylinder is leveled.

At the edge of the stud, the master fixes three bearings, for them he will hold this device. For greater convenience, a PVC pipe should be pressed onto them.

The workpiece is fixed in a vice, and a longitudinal cut is performed.

It remains to cut a piece of sandpaper, and fill it into the groove.

From two opposite sides of the cylinder, the author additionally fixes the paper with two self-tapping screws.

Here is a simple device turned out by the master. With its help it is possible to process both wooden, and metal preparations. Also, its size can be changed to fit your requirements and needs.When using drums of large diameters, it is advisable not to put the drilling mode on the screwdriver, and when the protection is activated, switch it to low gear (first speed).

I thank the author for a simple but useful tool for the workshop!

All good mood, good luck, and interesting ideas!

Author video can be found here.