It has already become colder, and winter is approaching. It's time to take care not only of warm things, but also of active heating devices.

In this article, the author of the YouTube channel “TOKARKA” will tell you how he made a simple catalytic heating pad.

This homemade product is very simple to manufacture, and can be made almost from trash. Also, complex machines will not be required, simple home tools.

Materials

- Copper wire

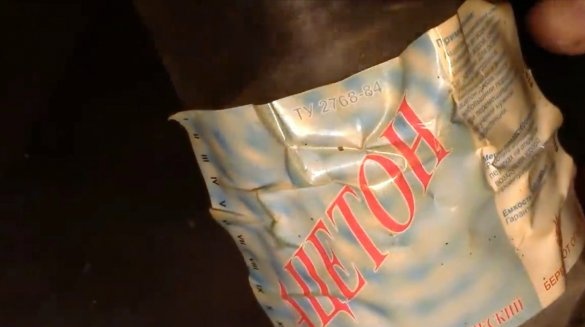

- Acetone

- Syringe, needles

- Copper sheet

- copper pipe

- Aluminum spray can

- Sandpaper

- Flux, solder

- Vata.

Instruments, used by the author.

—

—

—

—

-, metal drills

—

—

- Anvil, vise, hammer

- Scissors for metal, core, awl

- Pliers, wire cutters, file, file.

Manufacturing process.

Main element of this fixtures will be the catalyst. The author decided to make it from copper wire. A stranded copper wire is suitable. From it you need to extract one core. Of course, platinum wire is better suited for these purposes, but its cost is very high.

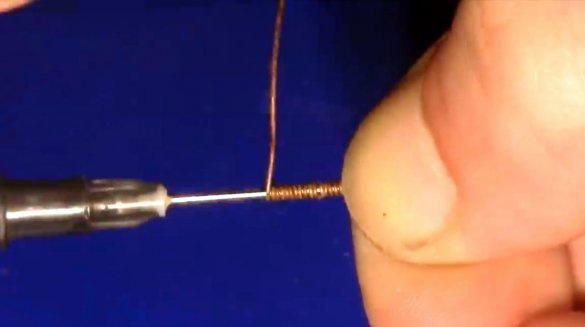

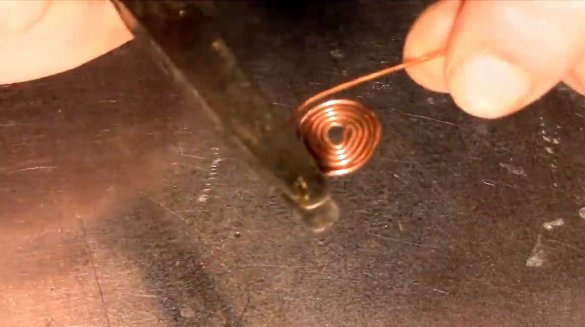

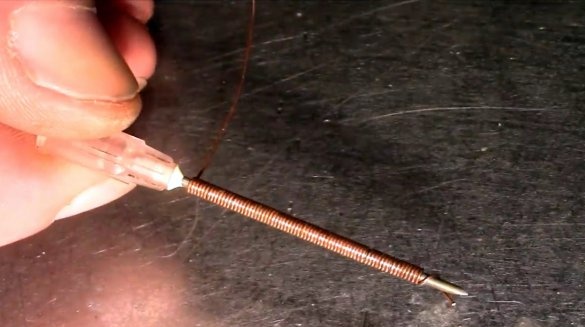

Then this copper wire is wound on a steel rod, or a needle from a syringe. The advantage of this method is that such a spring can be made of almost any length.

To maintain the shape of the spiral (especially when it is heated), it is necessary to insert a thicker copper wire into it.

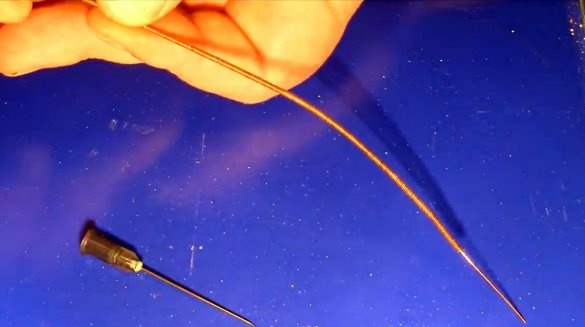

So, the master got such heating elements of various shapes.

As fuel, he will use ordinary acetone. Kovea warmers use refined gasoline for lighters.

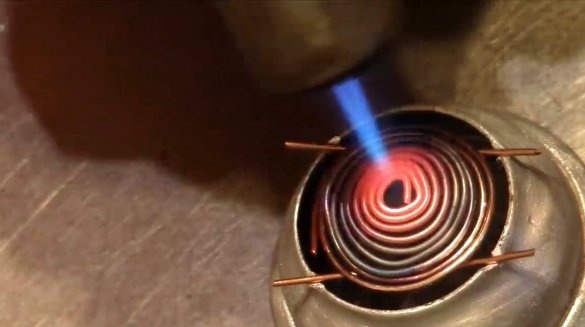

For the first experiment, the author placed cotton in a container and added 2 ml of acetone. In this test, the heating element is heated by a gas burner and placed above the cotton wool with fuel. From a heated spiral, acetone begins to evaporate more actively. The larger the size of the spiral, the more evaporation will occur, and the more heat will be released. However, the operating time is reduced.

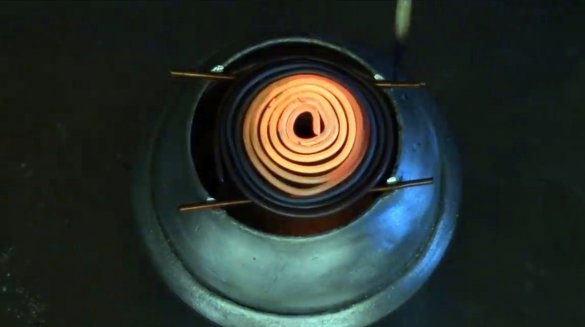

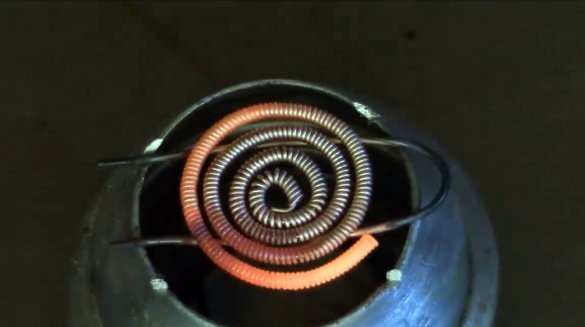

To check the operating time of the "open top" reactor, he uses another spiral in the form of a snail. In this case, too much vaporized acetone disappears before it can react.As a result, this design worked on 2 ml of fuel for almost half an hour.

Also, the heating element can be made of thick copper wire. It is very difficult to get a "spring" out of it, but a spiral in the form of a snail is easy.

Of course, it is better to use metal containers as a fuel tank, for example, such a small aluminum cap. It should be cleaned of plaque and paint with a dremel or sandpaper.

Here is another simple way to prepare another heater.

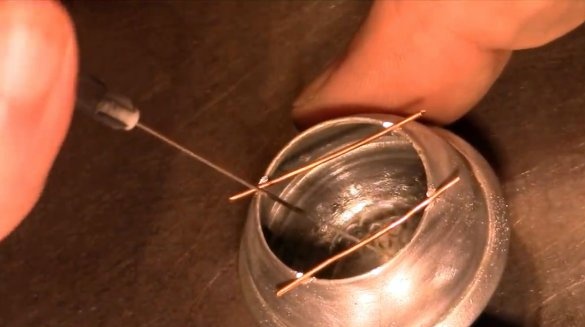

The turns of the resulting spiral need to be slightly moved apart, then a mixture of air and fuel vapor can pass between them.

On the upper edge of the container, the master cuts four grooves with a file and fixes a spiral on them.

The advantages of an aluminum case for heaters of this class is its excellent thermal conductivity, and lightness. The heating element must be made small, otherwise the evaporation rate of the fuel will be so high that it will not have time to react, and the efficiency of the device will decrease. In addition, you should achieve a case temperature of about 55-60 ° C, otherwise it will be possible to burn yourself.

This test version worked on 3 ml of acetone for almost a quarter of an hour, but the heat transfer was almost 3 times greater than in the previous test.

In the third experiment, the author wound a spiral on a thick needle, and rolled it into a snail.

This version also has a right to exist. However, in the oxidation of acetone, not very desirable reaction products are formed on the surface of the copper wire. They give a not very pleasant smell, but it is quite possible to use the device outdoors in winter. Also, this "reactor" can be built into a variety of devices, and even used to keep food warm. Their most important advantage is autonomous operation, which does not require power sources such as batteries.

Actually, as an enclosure, the author wanted to use an aluminum can of drugs.

However, at a flea market, he found such a device for sterilizing reusable glass syringes and needles. Its body is made entirely of brass and coated with chrome. If you can’t find such a thing, then you can make a heating pad case even from an old Soviet electrolytic capacitor.

The inner diameter of its upper part is 31.7 mm.

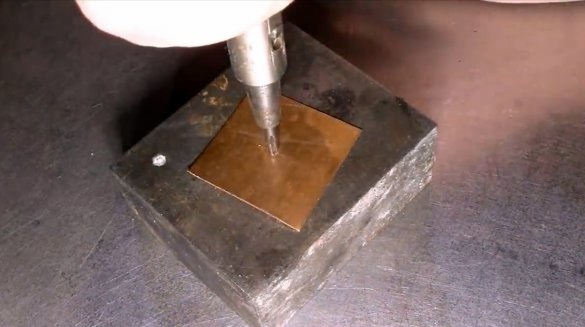

As a stub master makes a small square, and drills a central hole in it.

After aligning the workpiece, a disk is cut from it.

For convenience of further processing, the author inserted a screw into the hole and fixed it with a nut. As you can see, the disk is not yet included in the neck of the container.

You just need to fix the screw in the chuck of a drill or screwdriver, and grind its edges with a file.

Excess sterilizer parts as well as gaskets are removed.

The inner edge of the neck is cleaned with sandpaper.

Now a flux is applied to the edge of the body and it is tinned.

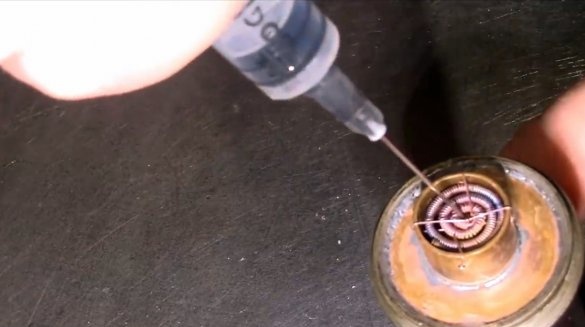

Inside the case, the author places the usual cotton wool, stuffing it quite tightly. Then the plug is pressed in.

After applying the flux, the plug is soldered to the body using a gas torch and a soldering iron.

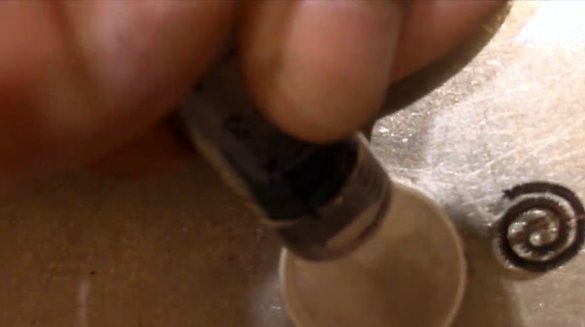

From the piece of copper tube, the master cuts off a small cylinder, and strips its edges.

This cylinder is soldered to the plug as follows.

After refueling and installing the spiral, it becomes clear that there is not enough oxygen for the catalytic reaction.

For better entry into the chamber, the author drills several holes around the perimeter of the cylinder.

Through the ventilation holes, the spiral can also be fixed with a thin wire.

And this time the reaction is poorly supported.

The author adds a few more holes in the cylinder, and also makes them on the cap.

In addition, the center hole expands with a stepped drill.

By changing the dimensions of the spiral, and the configuration of the structure, the author realized that the material of the spiral does not support a catalytic reaction. The wire was not made of pure copper.

Therefore, he made just such a snail. Tests with her were successful.

The most recent version of the spiral involves a small central hole. This design works very well.

I had to add a few more ventilation holes on the case.

And here is the final burner body temperature test. She was 58.5 degrees. In order to make the device convenient to use, and it does not lose the temperature in the open air in frost, its body can be glued with a cloth.

That's all, the hand warmer is ready! The latest version lasted for 20 ml of acetone for almost 8 hours. The heating pad can also be carried in the filled form, only the second tight cap is needed.

And for those who do not want to make this device on their own, I recommend visiting Aliexpress, the Chinese friends offer. Delivery speed is not very high, but in time for the new year and will arrive.

I thank the author for a simple but very useful idea for creating a catalytic heating pad!

All good mood, good luck, and interesting ideas!

Author video can be found here.