Master craftsmen often have to grind small parts. This operation produces a lot of dust. It was invented and manufactured to collect this dust. device.

Tools and materials:

-Plastic container;

- Adapter for connecting a vacuum cleaner pipe;

- clamp;

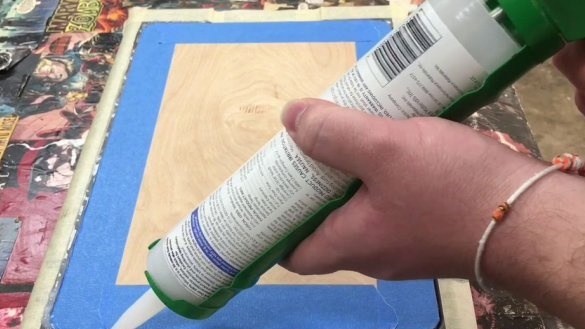

-Silicone sealant;

-Glue;

-Plywood;

-Sandpaper;

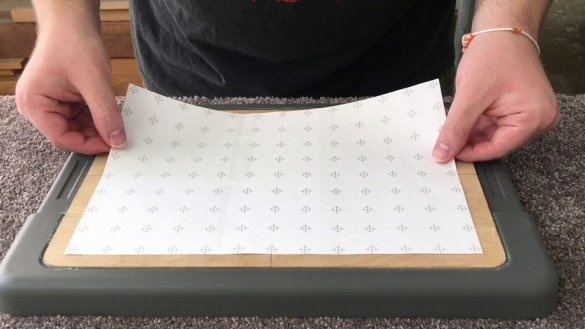

-Template;

- Paint tape;

-Marker;

-Rule;

-Screwdriver;

-Knife;

- Clamps;

-Circular Saw;

-Drilling machine;

- Joiner's glue;

-Electric stove;

Step one: install the adapter

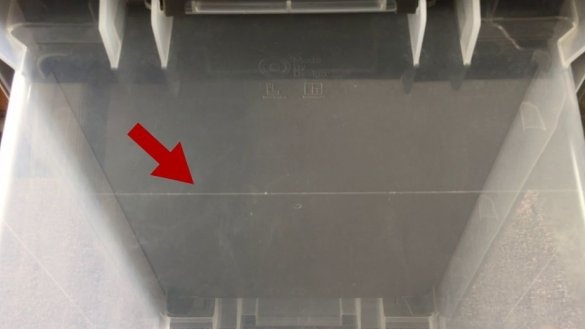

The first step is the master installs an adapter in the plastic container for connecting the vacuum cleaner pipe.

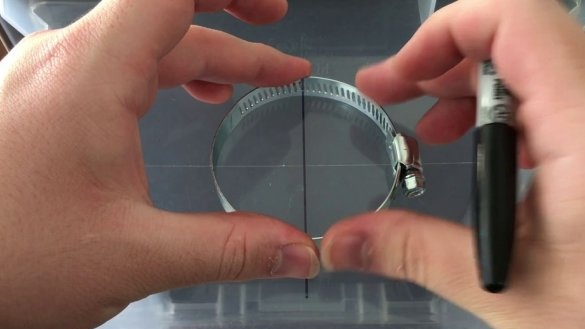

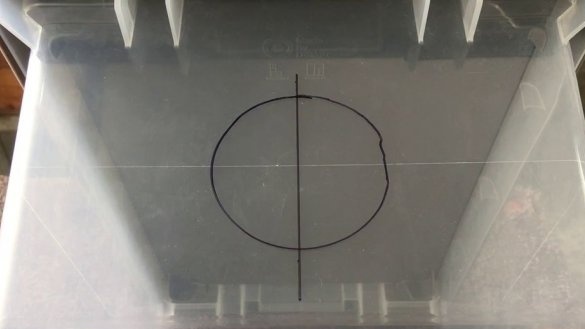

He puts on a metal clamp and tightens it, but so that it can be removed.

On the container wall marks mounting holes and holes for the adapter.

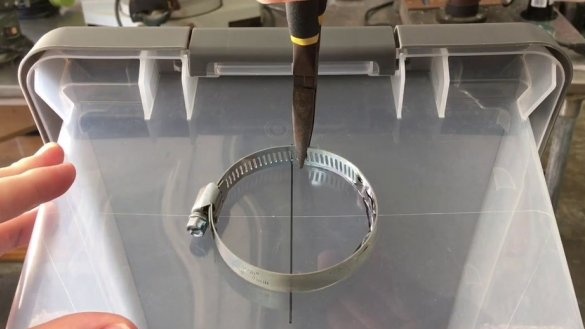

On a hot plate heats the clamp and burns a hole in the container with it.

Adhes the adapter.

Step Two: Cover

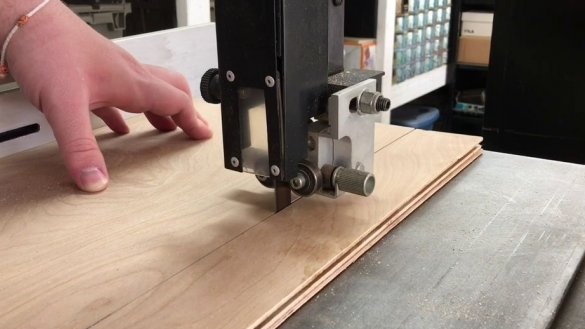

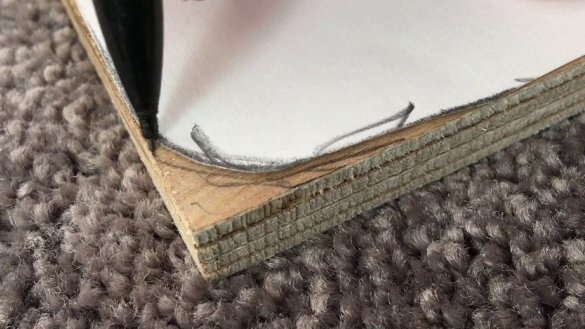

The master had 3 mm plywood. He glues it in three layers.

After gluing, cuts the plywood to fit the cover.

Sticks.

Step Three: Sealant

Tape the cover with masking tape and apply sealant in the groove between the plastic and the plywood.

Seals adapter mounting location.

Step Four: Holes

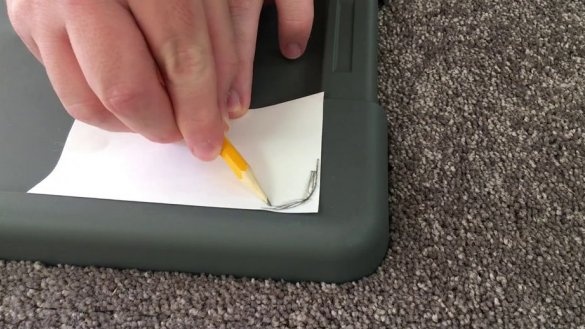

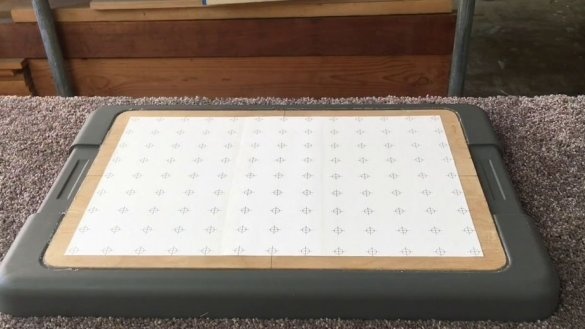

Prints a template and sticks to the cover.

Drills holes according to the pattern.

Step Five: Build

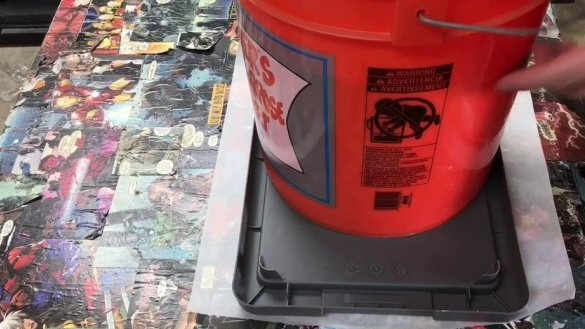

For better adhesion, sand the edge of the container.

Apply sealant.

Installs the cover.

After curing the sealant, you can connect a vacuum cleaner to the adapter and check how the dust collector works.

The whole process of manufacturing a dust collector can be seen in the video.