In this article, the Wizard will show us the technology of casting a bell from bronze. But the master does not just talk about casting, he combines different technologies in this article, from design and 3D printing to casting. Of course, not every master has the opportunity to do such a job, but there is something to strive for.

Tools and materials:

-Computer with software:

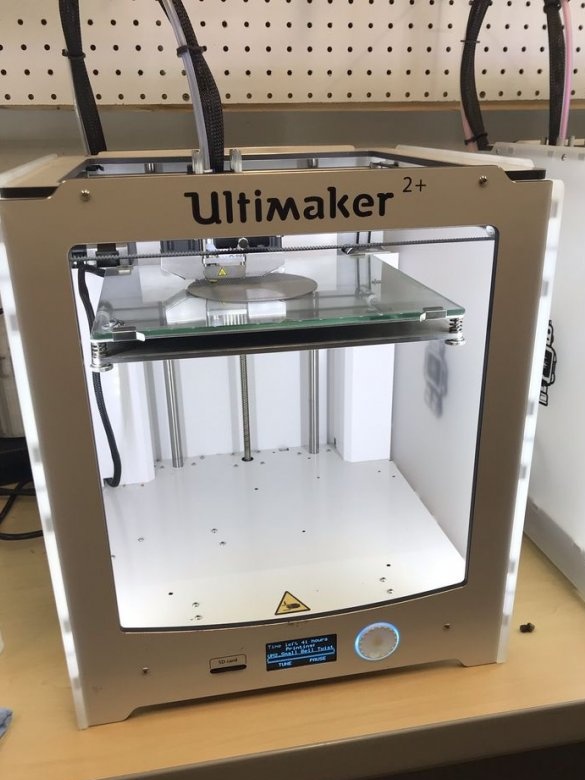

-3D printer;

-Propane burner;

-Wax;

-Scraper;

-Wire mesh;

-Gypsum mixture;

-Capacity;

-High pressure washer;

-Bake;

-Vacuum cleaner;

-USHM;

-Drill;

Reciprocating saw;

-Chisel;

-Hammer;

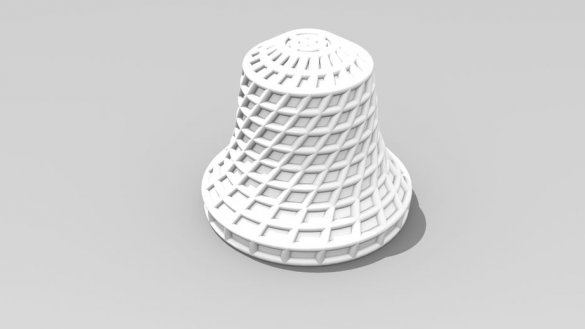

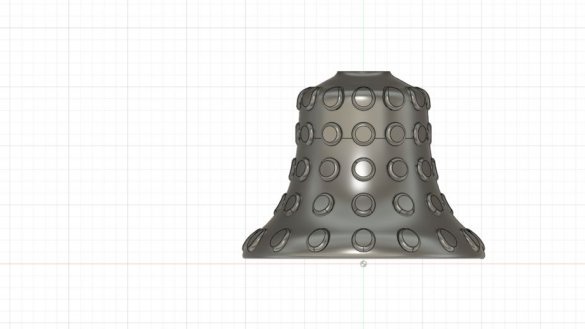

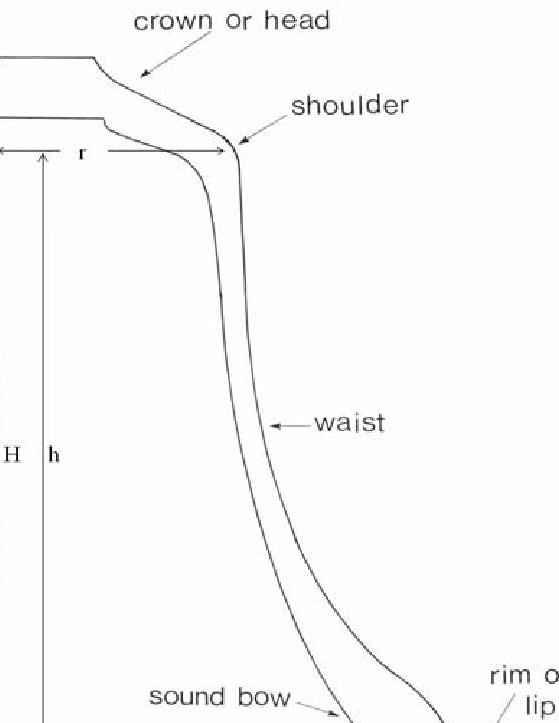

Step One: Design

First, the master makes the design of the bell and language. Draws form and decoration.

Step Two: 3D Printing

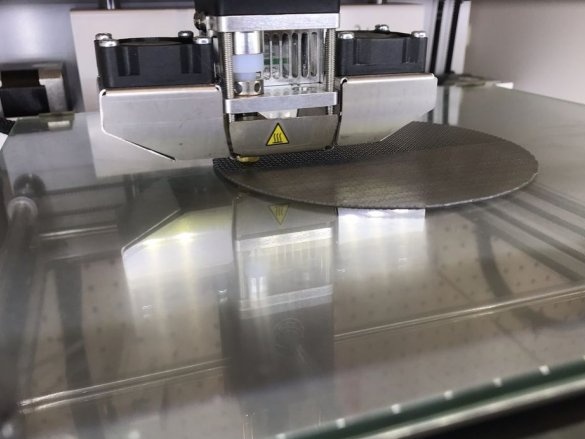

Next, the wizard prints the layout on a 3D printer.

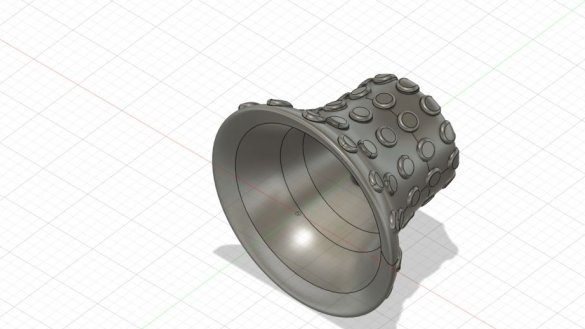

Step Three: Preparing and Filling the Form

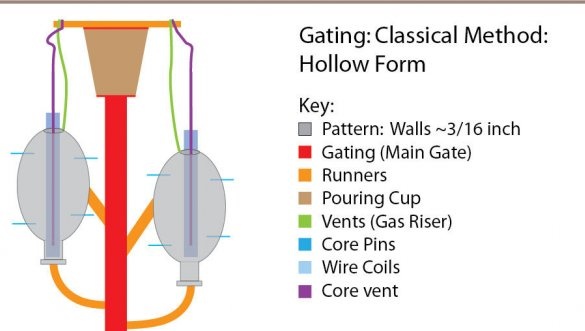

The wizard will cast several bells and languages. For pouring, the master uses various forms of plastic. For delivery to the form of the melt, the master makes a "tree", whose branches are wax. When pouring, the wax will melt.

Around the form, the master makes the frame.

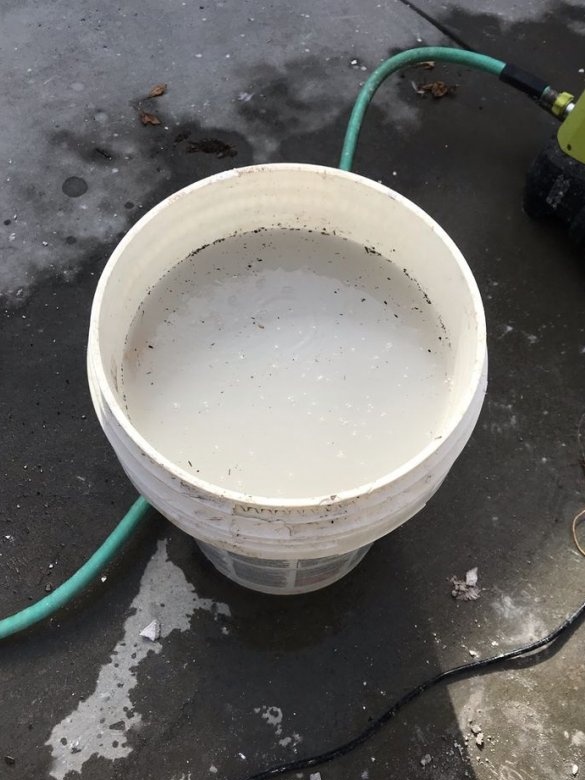

Knead and pour gypsum.

Next, the master places the mold in the oven at a temperature of 300-400 degrees per day. This will melt the wax and plastic molds. After a day, the master briefly raises the temperature to 1000 degrees. This operation guarantees the melting of all residues.

Step Four: Casting

This step is the most difficult in terms of equipment. The melting point of Bell Bronze (bronze, copper and tin) is 2000 ° C. The master melts the metal and pours on the molds.

Step Five: Cleaning

After casting and cooling the mold, the master cleans the workpiece from gypsum.

As you can see, the casting can be rough in some areas and clean in others. Although this molding process is somewhat rude, it does show the details down to the layers of printed filament.

Clearing such a complex shape is also not easy.

Step Six: Language

Then the master drills a hole in the bell and hangs his tongue.