This system is made according to the 3-in-1 principle. In the “Cyclone” version, I use it to remove dust, sawdust, fine chips and other bulk materials, for direct connection to a power tool (for suction of sawdust). In the compact vacuum cleaner variant, the system is used to dust off LCD panels, office equipment, as well as places where it is inconvenient to use a household vacuum cleaner (for example, on the upper shelves using a stepladder). In the blower variant it is used to clean the power tool, dry various parts after washing (it perfectly blows moisture out of all slots and blind holes), and to cool parts during soldering. Replaces compressor for air mattresses, pools, etc. It can be used as a compressor for a spray gun.

The idea was to make the design more convenient, reliable. Use in the design parts from the nearest hardware store so that there are no problems with the replacement. Improve the ease of maintenance of the system (cleaning, assembly, disassembly). Therefore, the design has changed, both of a universal vacuum cleaner-blower and of the Cyclone unit itself. Added optional dust bag. The previous design is still successfully used by friends. All I have left is a trolley (machine) and a synchronous start-up unit.

In the manufacture of the system was used:

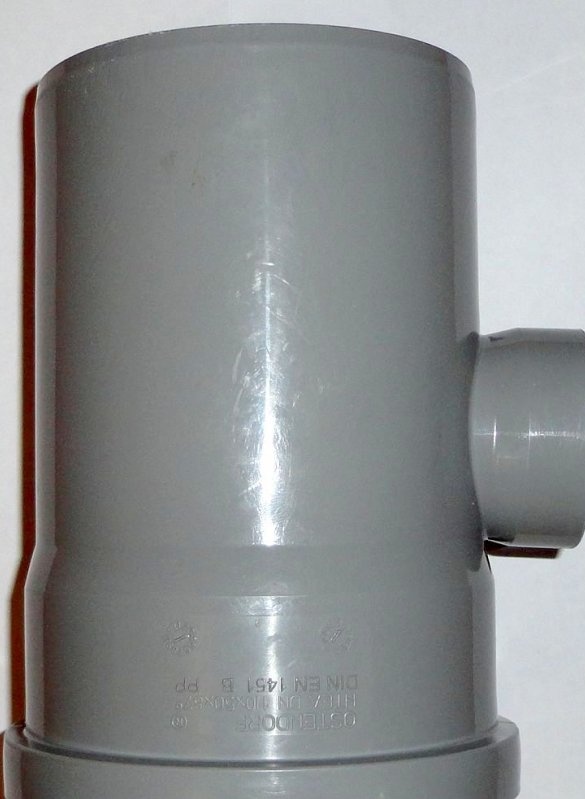

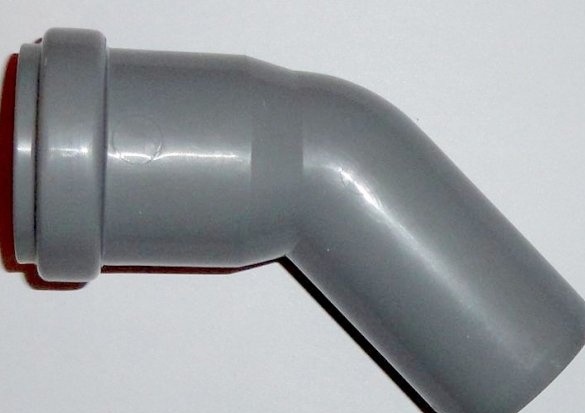

- Polypropylene pipes and fittings "OSTENDORF"

- Power block from the spray gun "Bosch PFS 65"

- Plastic 2.5mm thick

- Plastic 15mm thick

- Plexiglas 4mm thick

- Rubber sheet 2mm

- Funnel plastic d 120mm "Polymerbyt"

- Foam rubber

- Furniture handles

- Plastic furniture corners

- Radio components (according to the scheme)

- Fasteners M3, M4

- Buckets plastic 5L.

Of the tools used:

- drill

- milling cutter

- Hair dryer

- MFI type "Dremel"

- soldering iron

- Thermo-glue gun

- Screwdrivers, wire cutters, etc.

As the main structural material, OSTENDORF standard plastic water pipes are used, because they have a more even and neat design. The power unit from the Bosch PFS 65 spray gun is ideally sized for this construct and has an engine power of 350 watts, which is enough for this design.

The system consists of the following main parts:

- Universal vacuum blower

- Block "Cyclone"

- Optional dust bag

- Trolley (machine)

- Synchronous start block

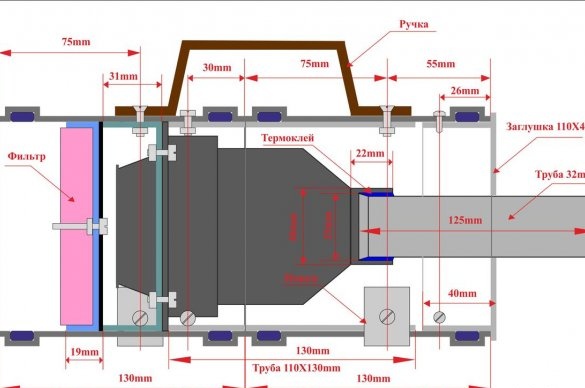

Diagram of a universal vacuum cleaner blower.

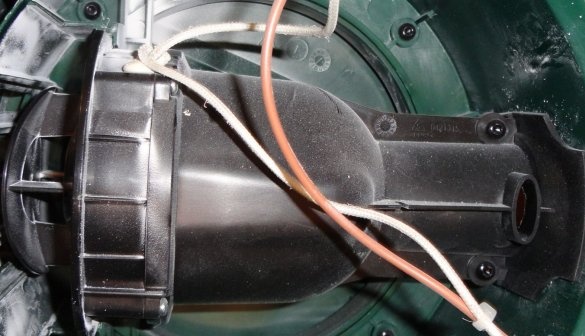

Power block from the spray gun "Bosch PFS 65"

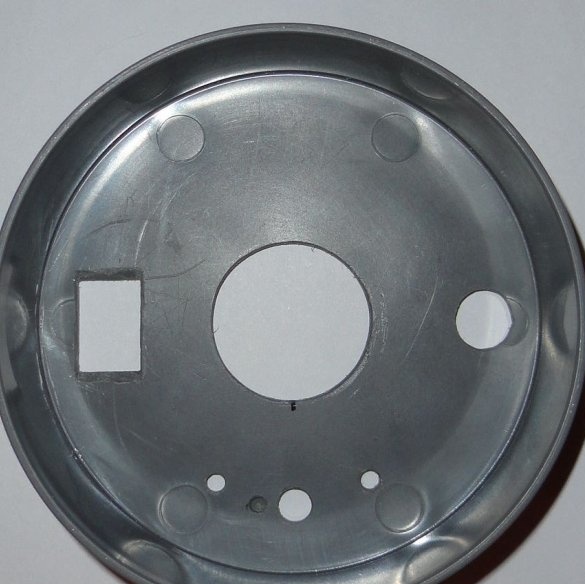

The case of a universal vacuum cleaner-blower is assembled from two connecting couplings d 110mm, a length of pipe d 110mm 130mm long and a plug d 110x40mm. Unlike the previous version of the vacuum cleaner-blower, the power unit is fixed much more securely. The unit is attached to the holder with four M3 screws. The holder is attached to the case with three M4 screws, which are simultaneously fasteners for legs and handles. The remaining screws are also M4. The holder is made of a plug d 110x40mm, in the center of which a hole is cut with a diameter of 78-79mm (other dimensions in the diagram). When attaching the power unit to the holder, the edges of the turbine casing were sanded and filled with sealant. The excess part of the turbine housing is cut off. A piece of pipe with a diameter of 32 mm and a length of 125 mm is fixed in the turbine housing with hot-melt adhesive.

The filter housing is made of a standard plug d 110mm. The gasket is cut out of 2mm thick sheet rubber and glued with Moment glue. An insulating tape was used as a sealant. For ease of removal from the housing and the possibility of additional fastening of the foam rubber filter, an M3 screw is fixed in the center.

Convenient fixture for removing the filter housing is made of a rack and a “lamb”.

The filter is cut out of foam rubber.

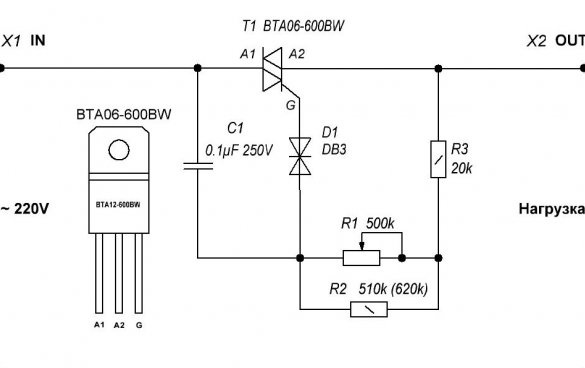

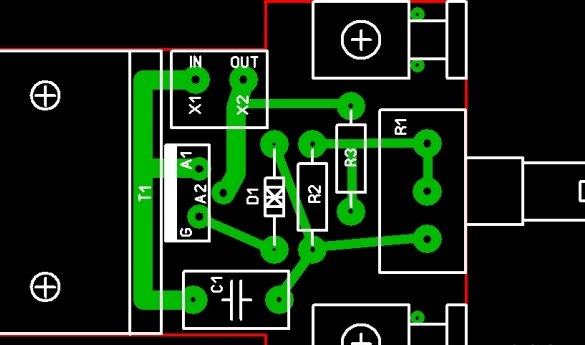

Scheme of a homemade power regulator (dimmer).

For ease of disassembly, the plug is mounted in the housing with three 3mm screws. The seal is made with electrical tape. Unlike the previous version, the network cable is attached through the PG7 cable entry, which is much more convenient. The power regulator is fastened with two M4 screws and a potentiometer nut. For ease of replacement, a switch is connected on the blade connectors.

Universal vacuum blower assembly.

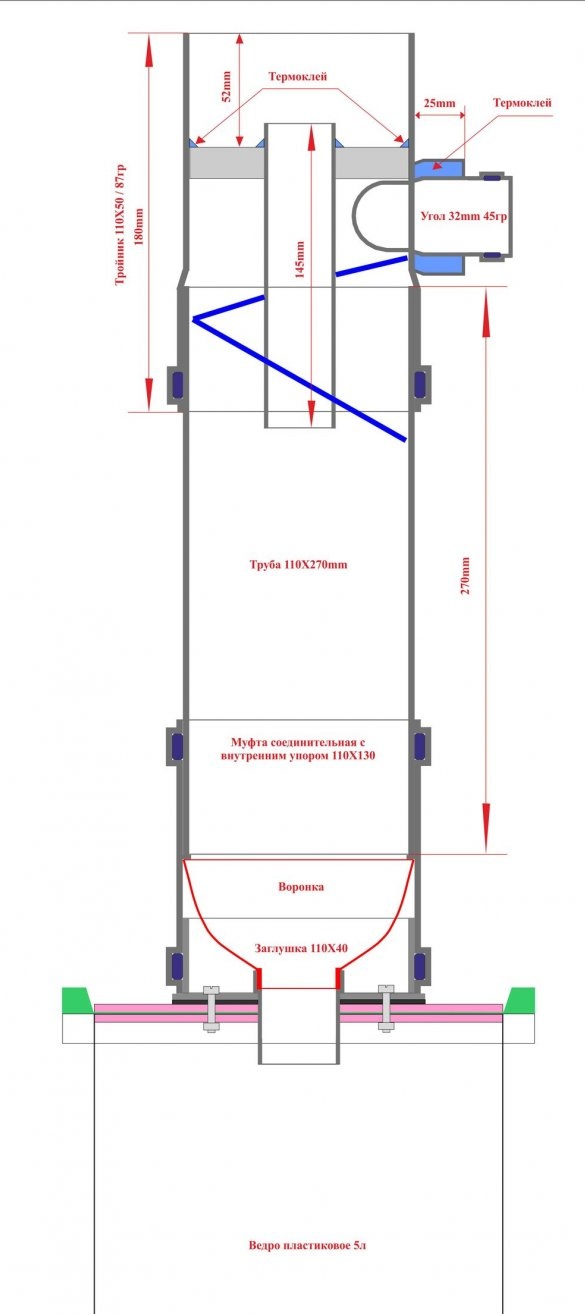

The Cyclone block consists of a vortex generator block and a container for collecting sawdust. The body of the vortex generator is assembled from a tee d 110x50 / 87gr, a pipe segment d 110x270mm, a coupling connecting with an internal stop d 110mm, plugs d 110x40mm. The sawdust collection tank is assembled from two 5L plastic buckets.

Scheme of the Cyclone block.

A part of the lateral branch has been cut off from the tee.

The ring is made of plastic 15mm thick. Fastens to the tee body with four 4mm screws. The ring is sealed with hot glue at the top.

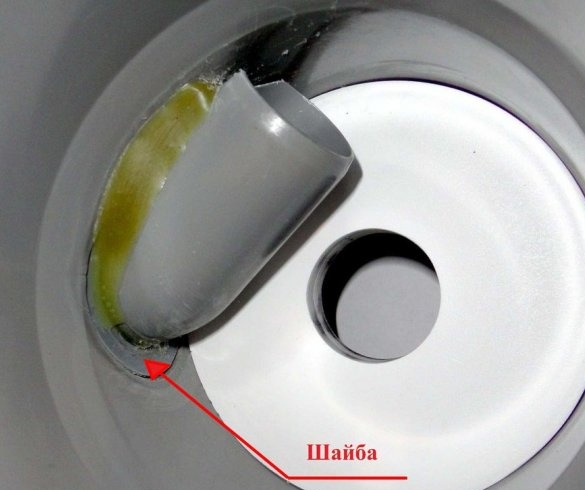

An angular tap d 32 / 45gr is fixed in the housing using an M4 screw and hot-melt adhesive. The curved washer is made of pipe d 110mm.

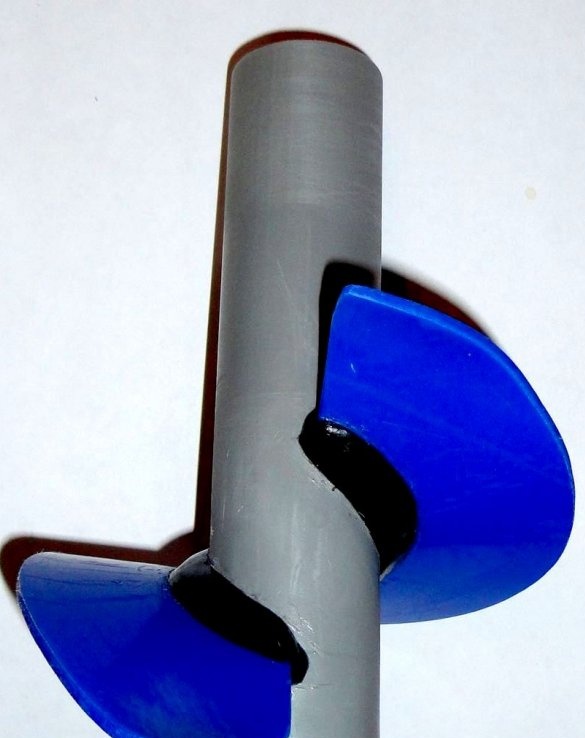

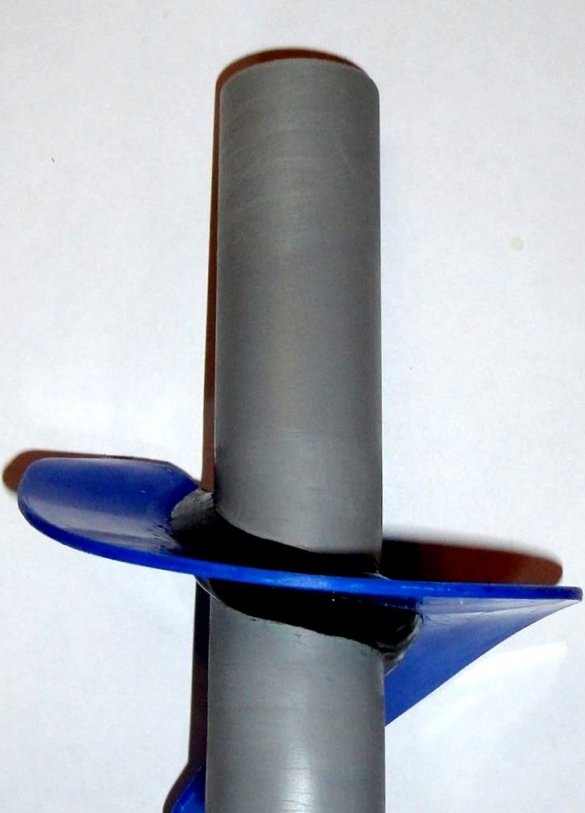

Unlike the previous version, the vortex-generator blade is made of thicker plastic 2.5 mm thick. The blade is bent with a building hair dryer and fixed to a d 32mm pipe with a 145mm long hotmelt adhesive. The pipe is tightly inserted into the ring and fixed with hot-melt adhesive.

Unlike the previous version, it was possible to achieve a minimum clearance between the blade and the body (through trial and error).

The funnel is cut off according to the inner diameter of the coupling. The neck of the funnel is made of a d 32mm coupling and secured to the funnel body with hot-melt adhesive.

The fastener for the bucket lid is made of two disks with a diameter of 194 mm from plexiglas 4 mm thick, which are installed on both sides of the lid and plug d 110x40 mm on which a rubber gasket 2 mm thick is glued. Due to this, sufficient tightness and the ability to easily replace the cover in case of damage is achieved. The fasteners are made with six M4 screws.

The sawdust container is made of a plastic bucket with a capacity of 5L and the inner insert made of the same bucket with two stiffeners glued into it (using hot melt adhesive) in the form of 4mm thick plexiglass rings.

As a result, the capacity has acquired sufficient rigidity, does not shrink under any operating conditions of the system. Thanks to the composite design, the bucket can easily be replaced if it is damaged. Also between the bucket and the insert you can insert a thin plastic bag for rubbish.

An additional dust collector is made of a connecting sleeve d 110mm, a pipe segment d 110mm long 125mm, a plug d 110x40mm, a pipe fragment d 32mm with an o-ring. The filter is sewn from cotton fabric.A ring cut from a pipe d 110mm is sewn into the edge of the filter. In the center of the plug, hot glue glues a piece of pipe d 32mm with an o-ring.

For dusting from LCD panels, radio equipment, office equipment, in hard to reach places, etc. A special brush of the Flute type d 32mm, 350mm long was made. As a stub at the end of the pipe a playing piece is glued. As soft brushes, a self-adhesive brush sealant for cabinets is used, which is additionally fixed with a thick thread. The diameter of the holes is 5mm. The edge of the seal slightly extends beyond the edge of the pipe to remove dust from the corners.

For the manufacture of the nozzle, a d 32mm coupling with an internal stop is used, into which a nozzle is glued with hot glue from the same funnel.

Using the system as a compact vacuum cleaner is quite convenient since in this form, the weight of the structure is only 2.1 kg (without a hose, but with a belt).

In the case of using the system as a blower, the hose is fastened with a d 32mm coupling.

For ease of operation, additional clamps d 32mm (pipe holders) are installed on the trolley. It has become much more convenient since basic equipment is at hand. Also, a wooden ramrod is mounted on the trolley for cleaning in case of blockage of the neck of the funnel.

On the rubber sealing rings at the junction of the system parts, the skirt is slightly cut off. When installing, the rings are turned outward by the skirt. Therefore, the parts are connected tightly enough, and when the parts are disconnected, the seal does not wedge.

Unlike the previous version, all the parts of the Cyclone unit and the additional dust collector are perfectly washed under a stream of warm water (there are no parts from chipboard). Then it is possible to quickly dry using a blower. Foam and cloth filters are also perfectly washed with soap and water.

At the time of this writing, the system is already in operation for a year. With the tasks I need to cope 100%.

If something is missing in the description, I hope these nuances can be considered in the submitted photos. I apologize in advance for possible errors and typos.

If you need additional information, write to the post office, I will try to be sure to answer. Feedback, ideas, suggestions for improvements to the design and comments are very welcome.

November 2019