Most likely, many of you have a drill stand in the workshop, or a drilling machine.

In this article, the author of the Hands from the Shoulders YouTube channel will tell you how he made a very simple and useful improvement for these types of machines, which allows you to easily and reliably fix the workpiece on the table during drilling operations.

Materials

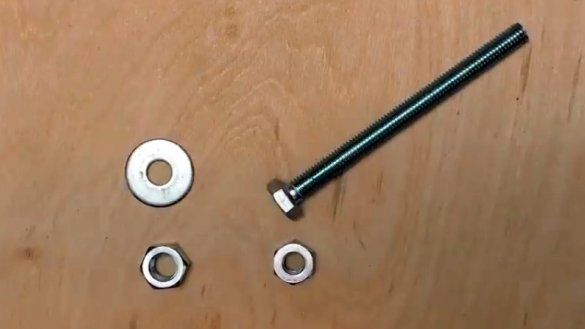

- Nuts, washers, M12 bolt

- Nut M14

- Steel round timber

- steel strip

- Spray paint.

Instruments, used by the author.

— Bulgarian

— 125mm diamond blade for metal and stainless steel

- Drilling machine, or drill stand

— Welding machine

- Vise, tape measure, marker, ruler, square.

Manufacturing process.

So, as the main parts you will need an extended M12 bolt, as well as a washer and nut.

In addition, you will need a steel round log of a similar diameter. You can also use a suitable steel pipe or profile pipe.

The master did not use a standard abrasive cutting disc, and replaced it with a steel with a diamond coating.

Such a disk cuts steel a little slower, however, it serves several orders of magnitude longer, which justifies its value.

After cutting the edges of the workpiece, these are the traces of the cut.

Next, a piece of round timber is cut to a length of 350 mm, although this is all individually selected.

Now an M14 nut is welded to one of the ends of the round timber. After this, the slag is knocked down, and the seams are cleaned.

In fact, almost all the details fixtures ready, and they are going as follows.

For homemade work, you will need another steel part in the form of a small plate, it can be made of a steel strip or corner. In the case of using a profile pipe as a lever, a plate is not even needed.

It remains only to weld a steel round with a nut to a rectangular billet. This must be done very accurately, the axis of the nut should be perpendicular to the plane of the plate. Then this structural element is cleaned and painted with spray paint.

This is how a special drill stand looks, which turns it into a drilling machine.

The M12 bolt head is ideal for a T-track in a rack table.

Everything is ready for testing. The clamp height can be adjusted with a nut, and the part is fixed manually.

Most interesting, the height of the fixed part depends only on the capabilities of the rack itself, and the length of the guide bolt.

For better fixation of metal workpieces, you can put a small notch on the bottom of the plate, or stick a piece of sandpaper on it. If you plan to work with parts whose surfaces are undesirable to damage, then stick on a plate a piece of light sheet leather, silicone, or other non-slip material. An even better reinforcement is the grip of a piece of skin lubricated with a small amount of natural rosin. It will create so much friction that the part does not jump out of the clamp under any conditions. It is this property of rosin that violinists and cellists use, rubbing the surface of the bow with it. It is also possible to use alcohol solutions of rosin; when dried, they will also restore properties and increase the friction force by several orders of magnitude.

I thank the author for a simple but useful improvement for a drilling machine or drill stand.

All good mood, good luck, and interesting ideas!

Author video can be found here.