In this article, the master will show us how to weld aluminum without argon welding. According to him, the compounds are strong, welding is very simple, and at a cost it is several times cheaper than argon.

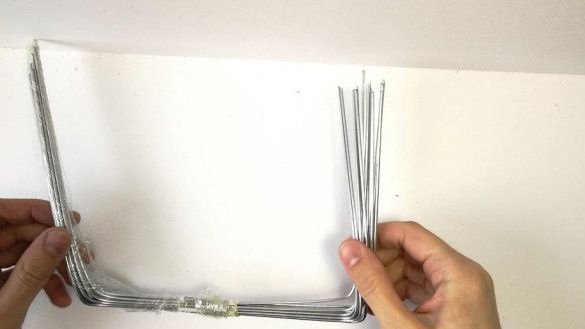

The following tools and materials are needed for welding: aluminum scrap (tube, bolt, etc.), a propane torch, a vice, pliers, and the most important material is aluminum brazing wire. Such a master buys wire on Aliexpress.

The burner is also not simple, but for soldering low-temperature solders. The heating temperature reaches 1300 ° C.

Before welding the necessary part, the master advises to practice on unnecessary aluminum scrap.

For a weld to be durable, a certain temperature is needed. You can neither overheat the seam, nor heat less than necessary.

First, the master trained on an aluminum tube. I made a cut on it and proceeded. As the saying goes, "the first pancake is lumpy." The master overheated the pipe, and it melted. The second attempt was more successful, the only solder was slightly swollen.

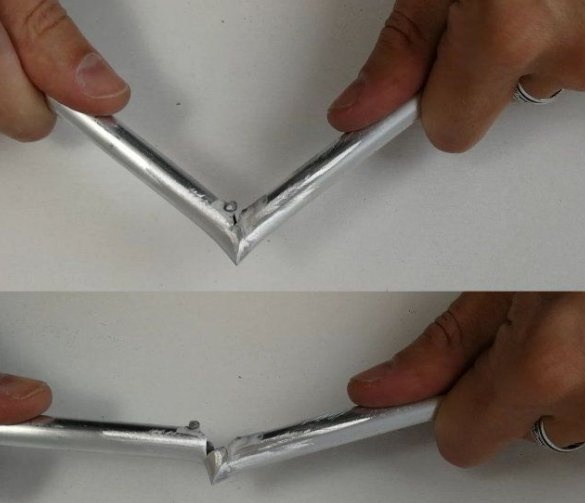

Then the master tries to weld two tubes cut at an angle.

The upper part was soldered well.

The master welds the inner corner.

When trying to break the tube, the lower seam could not stand it, but the upper one was quite durable. The photo shows that the gap went to the side.

The next experiment with a profile pipe. The walls of the pipe are thicker and need to be warmed up more. When soldering, part of the material got into the profile, such moments must be taken into account.

Having cleaned the weld, a good result was obtained.

With the last step, the master welded a nut to the bolt. After the operation, the master decided to try to unscrew the nut, but he did not succeed. Those. the connection is strong enough.

Thanks to the master for useful instructions.