In this article, the author of the Woodsmith YouTube channel will tell you about the methodology for more efficient and accurate processing of thin wooden plates in the thicknesser.

Materials

- Ф inch MDF panel

- Double-sided tape.

Instruments, used by the author.

- Reysmus

- Caliper.

Manufacturing process.

First, the author cuts a board from the MDF-panel according to the size of the wooden workpiece, which must be passed through the surface gage. On top of the MDF panel, double-sided tape is glued with two strips, thanks to which the wooden board laid on top will be securely fixed on the supporting plane.

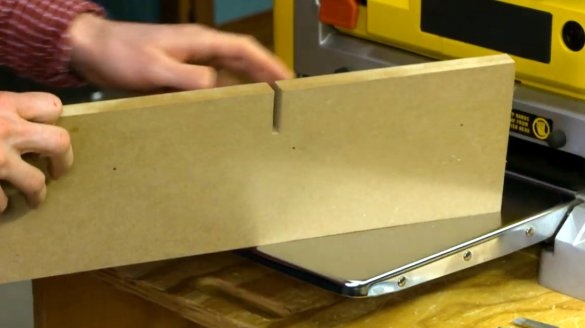

Then, approximately in the middle of the supporting panel, a slot is made for control measurement.

Now the author removes the protective film from the adhesive tape and carefully attaches the blank on top of it, so that there is a small gap between the blank and the edge of the supporting board, not covered by adhesive tape, and the slot remains open.

Next, the master takes his vernier caliper and measures the initial thickness of the board through the slot. Thus, thanks to the slot, he does not need to unfasten the workpiece from the fixing surface.

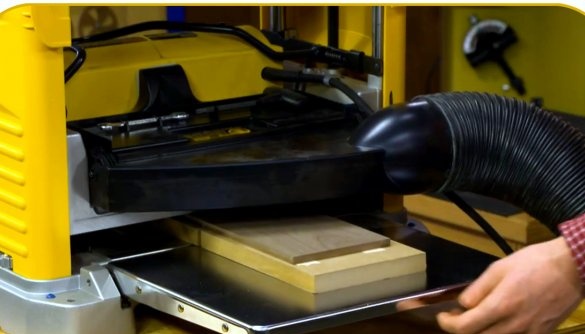

Now the author passes the board through the thicknesser.

And again he makes a control measurement. So you can skip the part several times, removing a minimum of material until it is the required thickness.

Of course, this method is also suitable for processing thick workpieces from which you need to remove a small layer. And do not forget about safety measures!

I thank the author for a simple but useful technique!

All good mood, good luck, and interesting ideas!

Author video can be found here.