This workbench is easy to disassemble and assemble in a new place. The workbench has a vertical vise and storage boxes. The width of the workbench is about a meter, and it is placed in the trunk of a car, and the material for it was boards from pallets, old door frames, etc.

Tools and materials:

-Lumber;

-Hacksaw;

-Drill;

- Planing machine;

-Threaded rod;

-Guides;

-Pens;

MDF;

-Construction hair dryer;

-Plane;

- Clamps;

- Joiner's glue;

-Fasteners;

-Linseed oil;

-Chisel;

-Hammer;

-Profile;

-Drill;

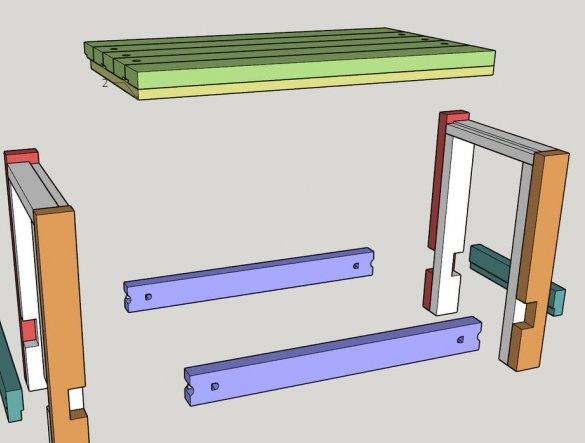

Step One: Countertop

From the boards from the old door frame, the master removes the laminated layer, warming them with a hairdryer. These boards are sampled and will be the bottom layer of the countertop. The master collects a shield from them, and the top layer of boards is attached to it.

Step Two: Feet

The basic shape of the legs is the big “P”.

The master makes sawing boards. Rounds off blanks.

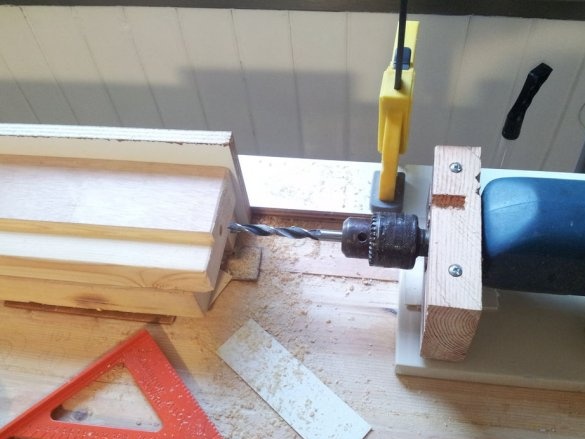

Makes marking for connecting grooves.

Cuts out grooves.

Collects legs.

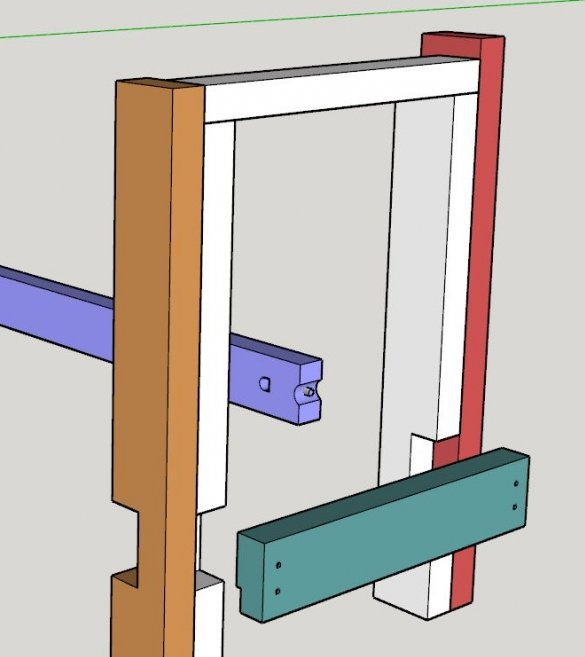

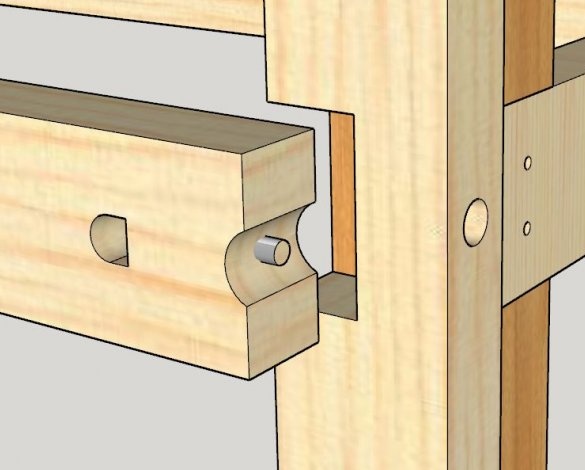

Step Three: Connecting Bar

Now you need to make the connecting beams.

The bars are attached to the legs with bolts. This will enable their dismantling, if necessary.

Step Four: Install Countertops

The tabletop is also bolted to the base. After assembly, the master covers the workbench with linseed oil

Step Five: Vise

In one of the legs the master drills a hole.

In the board, which will act as a movable sponge, also drills a hole.

Pre-assemble the node.

For mounting the rear nut, it makes and installs a ferrule.

The master made a guide for a vice from a profile pipe. I drilled a series of holes in the pipe, and made a hole in the lips to fit the profile.

Makes a handle for the screw.

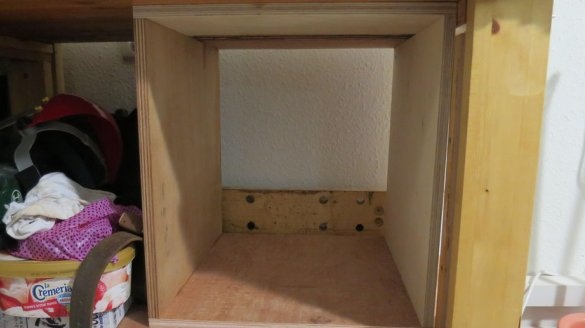

Step Six: Crates

The last step is the wizard sets the boxes. Adds an MDF sheet to the bottom of the workbench. Makes a shelf for boxes.

Makes boxes.

Sets guides and handles.

All is ready.

In the video below you can see the assembly process of the workbench.