I welcome all fans to craft, I propose to consider the instructions for the manufacture of stove stoves made of sheet steel do it yourself. Inside the furnace is lined with heat-resistant brick, which protects the steel from overheating, and also allows you to accumulate a little heat. For the manufacture of the furnace, the author used a bending machine. In the upper part of the furnace there is a rather large plane, which should be very hot. On this plane you can cook or heat food. The stove has a large firebox with a large door, and there is also a convenient blower and an excellent ash pan. If the project interests you, I propose to familiarize yourself with it in more detail!

Materials and tools used by the author:

Material List:

- Sheet steel;

- a piece of a round pipe for a chimney;

- steel plates;

- sealing cord for furnaces;

- door hinges;

- bolts and nuts;

- grate;

- heat resistant brick;

- square pipes for legs;

- heat resistant paint.

Tool List:

- grinder;

- bending machine;

- tape cutting machine;

- welding machine;

- tape measure, marker and other measuring tool.

Manufacturing process homemade:

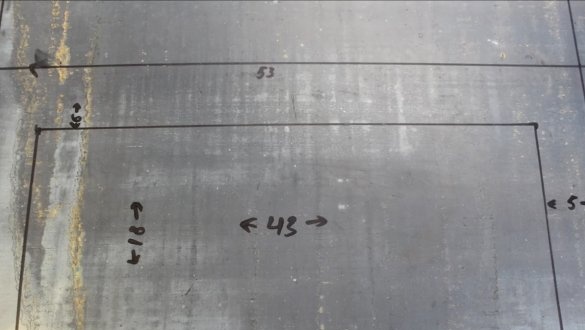

Step one. Cut the material

First of all, the author drew all the necessary details on a sheet and started cutting. If you are interested in sizes, they are all in the video. Cut the author with a grinder. At the end, the resulting billet was left to bend on a bending machine, and the finished case for the furnace turned out. For the furnace, it will also be necessary to cut the bottom and the smoke pipe from a piece of round pipe.

Step Two Firebox and ash pan sleeves

Around the furnace window and the window for cleaning ash, you need to weld a frame of steel plates. Then the doors will rest on these frames, and an insulating cord will run along the door contour.

Step Three Damper

In the smokestack, the author mounted a damper so that after the flowing it was possible to close the draft through which heat would fly out of the room.Be sure to cut out a piece of metal in the shutter so that it does not close completely. This is done for safety, so that in case of which carbon monoxide does not go into the room.

Step Four Doors, cover, legs

We make doors from sheet steel, their edges can be bent with a bending machine. Each door has a groove along the contour, into which the author puts a sealing cord.

The lid for the furnace is made of thick sheet steel, since it will heat up to high temperatures. If there is no such steel, you can also cover the lid with heat-resistant brick.

The author also made a door for blowing, the sleeve was made of a piece of a square pipe. To fix the door with a certain clearance, the author welded a nut to it and wrapped a bolt.

The legs for the furnace are made of profile pipes, at the bottom there is a grate of steel plates. This lattice can store firewood, dishes, and so on.

Step Five Brick

Inside, the author overlaid all the walls of the furnace with heat-resistant brick, he was laid on the edge. This design will not allow sheet steel to overheat and burn. Also, the brick will allow you to accumulate a certain amount of heat. The furnace grate was installed in the furnace, special steel plates were welded to fix the brick.

The finishing touch was an additional inner door, its author hinged. This door does not allow smoke to escape into the room when tossing firewood.

That's all, now the oven is ready, you can paint it with heat-resistant paint and install it in the right place. The author did not show us what she is capable of, but since the area of the furnace is considerable, it should give out a lot of heat, and there should be no problems with cooking on the cooking plane.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!