I welcome all fans to craft, I propose to consider the instructions for making the simplest rack for the grinder do it yourself. Homemade Designed for a variety of everyday tasks, for cutting, grinding and other work. As a hinge, the author adapted a cheap “hinge” type door hinge. In such a joint there are not weak backlash, but for domestic purposes this is not so important. The Bulgarian is attached to the boom with a steel clamp and is adjustable to the square. The author collected the basis of wood, the bed turned out to be almost free. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- steel clamp;

- door hinge "arrow";

- wooden block;

- MDF, particleboard or other base material;

- self-tapping screws;

- door spring.

Tool List:

- drill;

- a hacksaw;

- nippers;

- screwdriver;

- square.

Homemade manufacturing process:

Step one. Base manufacture

As a basis we use a sheet of chipboard, plywood or other sheet material. We fasten the bar to the base, to which we will fasten the hinge. Well, then we attach our door hinge to the bar. At the end of the door hinge, drill a hole for the mounting bolt, which is wrapped in a hole for the front handle of the grinder. We fasten the loop well with screws to the bar.

Do not forget to attach to the base legs that will not slide on the table.

Step Two Spring

We fix the grinder to the hinge, it is screwed with a bolt, as well as an additional steel clamp. In order for the grinder to return to its original position, we put a spring on the bed. Such a spring can be bought at a hardware store, they are put on the door. The author shortened the spring by simply cutting off the excess.

We hook one end of the spring to the handle of the grinder, the author drilled a hole in the handle and the spring is fastened with a screw and nut. And fasten the other end to the bar through a hook or other fastener.

Step Three Adjustment

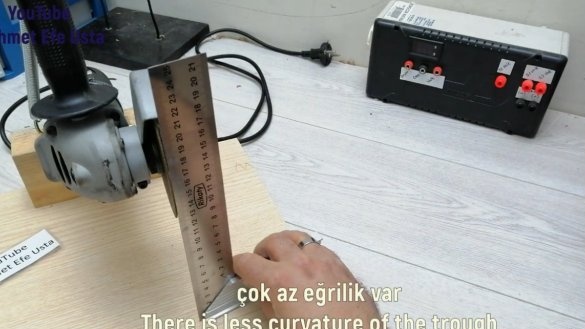

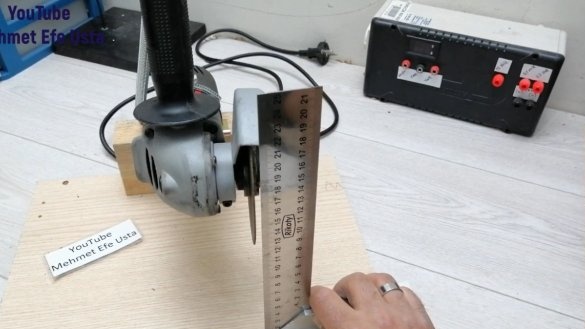

We take a square, put a new cutting disc on the grinder and see if the disc is perpendicular to the plane. If there is curvature, release the clamp and turn the grinder a little to the desired angle.

Step Four Stops and tests

The author made stops from pieces of boards, the material of the bull was cut by the finished homemade product. You can put a circular disk on a grinder, but be careful with it, never stand in front of the grinder so that it does not fly into you when jammed.It is safe to put on a grinder a special three-tooth disc on wood.

Also, the author puts on the grinder flap discs, it turns out a kind of grinder. Well, and, of course, the machine easily cuts steel pipes, plates, and other materials steel parts.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!