In this article, we will look at how the Master made a metal ring with a wooden insert. The master used stainless damask steel as the main material. I used a nut for insertion.

To make the ring, the master used the following

Tools and materials:

- Stainless damask steel;

-Lathe;

-Drill;

-Lubrication;

-Rule;

-Knife;

- Walnut veneer;

-Sandpaper;

-Glue;

-Acid;

-Soda;

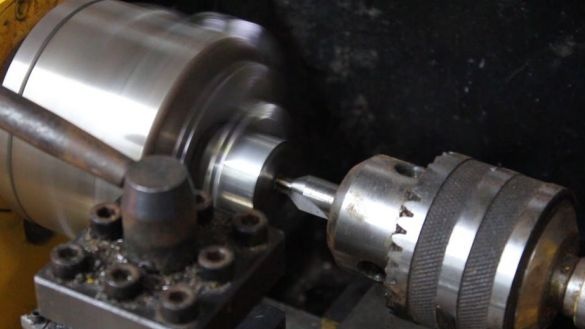

Step One: Drilling

In the first step, the master clamps the metal workpiece in the lathe chuck and drills through holes. Steel is very hard and the master does everything in a hurry using grease in the drilling process.

Step Two: Workpiece Processing

Further, the master cuts off the excess part of the metal and brings the thickness of the workpiece to 8 mm. Chamfers the inside of the workpiece.

In the middle of the ring makes a groove.

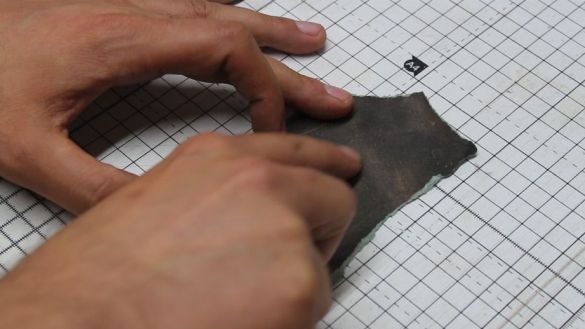

Step Three: Wood Insert

The master uses walnut veneer to insert. Cuts a strip of the desired length and width. One edge is sanded with sandpaper as thin as possible (it will be glued under the second edge of the veneer).

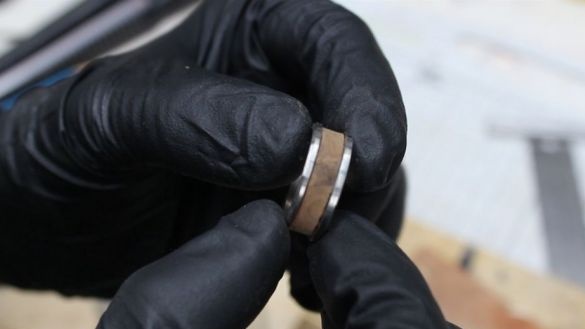

Then with the help of super-glue sticks a strip of veneer to the ring.

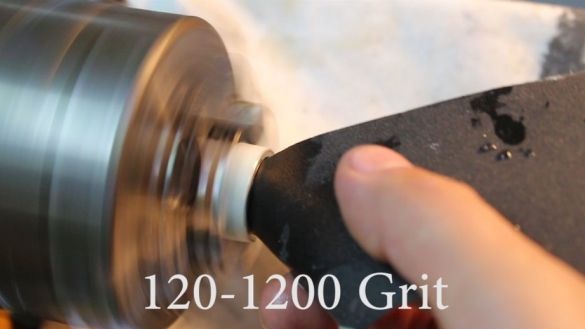

Step Four: Sanding and Coating

After gluing the insert polishes it.

Covers with transparent glue on top.

Grinds again.

Step Five: Etching

Next, the master places the ring in an acid solution for 30 minutes. Then it is extracted and placed in a soda solution. Washes with water. After this procedure, a pattern appeared on the surface of the ring. Polishes the ring again.

The ring is ready.

The whole process of making the ring can be seen in the video.