Garage excellently wintered - it's time to deal with it seriously.

How is the foundation made? Read here, and about walls and roof.

Some of the materials I have left from last year. This is a tile on the garage floor, paving slabs on the blind area and several rolls of hydroglass, so that moisture does not get into the garage. Before laying the tiles inside it will have to be welded together (you need to buy a welding torch!). There were enough rolls (I counted) to cover the garage across and along. It pleased! It was also necessary to plaster the walls of the garage inside and out. It was difficult only with the second floor (it, as I already wrote, was assembled from foam blocks) - poor adhesion. What is more profitable: buy the finished mixture or interfere with yourself? Cement has not risen in price since last year, ZIL sand cost 3,500 rubles. I decided that it’s more profitable for ourselves.

It was necessary to plaster about 200 m², and I did not find prices less than 30 rubles / m². Were also bought 10-mm beacons at 25 rubles / pc.,

bars with a cross section of 30x40 mm at 70 rubles / pc.,

and also a plaster grid at 220 rubles / roll. and the cheapest liquid soap for adding foam blocks to the mortar.

It was decided to start plastering work inside the residential area. Bars were fixed horizontally with an interval of about 1 m (for subsequent lining). A grid was fastened between the bars. The bars were used as guides for plastering.

On the ground floor lighthouses were used. Lighthouses were exhibited on the Rotbant, which saved on a layer of plaster.

From the outside, everything was displayed on the lighthouses, of course, taking into account foam concrete and sand concrete blocks. To secure the transmission of moisture from melt snow, I (remembering once this advice) bought “liquid glass”

and the last 80-100 cm of plaster came with this additive.

Having finished with the plaster, they took up the floors. At first they put hydroglass in two layers and welded it with a gas torch. Tiles inside the garage with dimensions of 350x350x40 mm were laid on a dry mixture of cement and sand in 1: 2 proportions. We started from the entrance gate to put a metal mesh under the first row. By bending it out and concreting, it was possible to make a smooth check-in to the garage. Then the floor was spilled several times with water.

The blind area made of slabs 500x500x50 mm was laid on a dry 1: 3 mixture with a slight slope outward and spilled in the same way.

Then I had to go to the store and buy a finely divided M300 mixture for grouting the joints between the tiles. She was also shed several times.

Then, bending the net to the site, the entrance to the garage was concreted.

The ceiling of the 1st floor from the bottom is hemmed with OSB (Oriented Chipboard). Its thickness is 12 mm, dimensions 1250x2500 mm - at a price of 600 rubles / sheet.

It took 8 sheets. First, an isospan (vapor barrier) of 55 μm was shot to the beams with a stapler, then the OSB was hemmed. This will subsequently make it possible to lay insulation blocks between the beams.

Then a non-standard metal door was ordered for an opening of 800x1890 mm of such a design that the passage remained maximum.

In order to secure the door in a 4-slot unit, a frame of 800x1890 mm from the 50th corner was ordered. The frame is installed inside and welded to the door frame with steel stripes.

Then the voids between both frames were plastered.

The lock is a cylindrical 3 crossbar. A valve is installed inside.

The door cost me 25,000 rubles. with delivery and installation.

Not far from mine cottages (Fryazino) there is a company that itself makes plastic windows from the REHAU profile, which is advertised in this way. There I ordered a window (900x1050 mm) along with the ebb. It cost me only 12,500 rubles. (with delivery and installation). Outside, the window is covered with a brown laminate (matching the roof and door), inside - white plastic. There is also a brown mosquito net.

The double-glazed window is a 2-chamber with energy-saving properties, since a thin layer of silver is applied to the glass from the inside (this was stated on the label glued to the glass). The slopes on the outside are made perpendicular to the wall, on the inside with a slope to the outside (the platform under the windowsill remains horizontal).

Nearby, I ordered a manual sectional lifting gate (I saved approximately 12,000-15,000 rubles), so the gate cost me 52,000 rubles. with delivery and installation. Section sandwich panels are 40 mm thick. The first and last panels have rubber seals. Seals are also laid along the vertical walls of the gate.

Workers began by installing the frame.

Then the doorway gathered

and under the loops connecting the individual sections on the inside reinforced plates are welded.

At the same time, rubberized rollers were installed, the brackets of which are also loops.

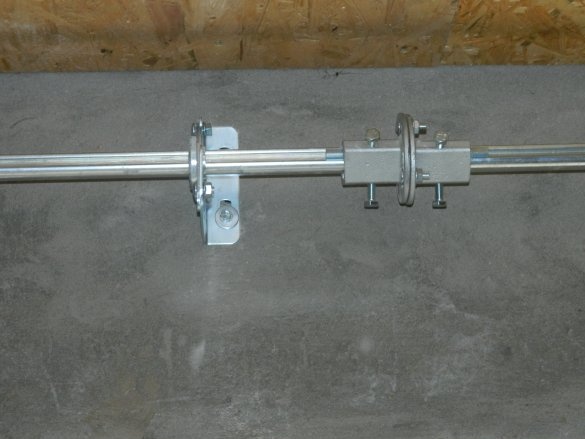

In order to hang the door in any state, two torsion springs with drums under a 4 mm cable were installed, which was attached to the top panel.

On springs in an unstretched state there are marks that allow you to tension the springs equally. After tensioning both springs in the middle, they were connected by a clutch.

And finally, a bolt lock was installed, which at the same time serves as a handle for raising the gate.

The following year, there was a fine finish and a second floor. I spent all-about-all-230,000 rubles. Gates, doors and plastering were the most expensive this season.