In this article I want to tell you about how to make a street roaster on your own from such unusual material as disc harrows. The author of this homemade is the author of the YouTube channel Good Master. It was he who, a couple of years ago, in one of the magazines spied the idea of how to make a plate from a harrow. He brought this idea to life, but since the disk was very large, the plate turned out to be heavy and inconvenient to take it with you to nature.

And so he was lucky to find another disk, but of a smaller diameter. The good Master decided to upgrade his original product, collecting one thing from two disks - a street brazier, which will be discussed in this article now.

In order to make this homemade product, the author needed:

-USHM with a metal brush,

-welding machine,

Drill with a metal crown

- brush, paint, stationery knife,

nippers

- discs from a harrow,

-shoulder arms!

First of all, the author cleans the surface of the first disk, one that was already a finished product from rust, soot, soot and everything else. Clean workpieces are much nicer to work with. The welding process is better and before painting do not have to work out to clean the surface.

For alteration, the author acquired three elements of cold forging, which are called voluta and a ring, which will be a fastener of curls.

After preliminary measurements, the author determines the position of the ring on the spiral elements, makes a markup and proceeds to the assembly process. Having attached a ring to the attached parts, it grips them by welding. Just a little to be able to correct the angles if necessary. As a result, the author gets this design.

Now the resulting design is covered with a disc for fitting. Levels it on legs so that the bowl sits exactly without distortions and seizes by welding. After the author is convinced that everything is going as it should, he carefully scalds all the junction points with a support ring and a bowl. To make the product more beautiful, as well as to increase strength, several smaller elements are purchased and welded to the lower parts of the legs, filling the void.

After welding, the product is degreased and you can start painting. To paint the author is black enamel.The bowl itself is heat-resistant up to 1000 ° C to prevent burning of the paint, and the legs are usually matte. The only thing I would like to correct is, in my opinion, that the legs, at least the part that comes into contact directly with the bottom of the bowl, must also be painted with heat-resistant enamel.

While the painted surface dries, a patination tool is prepared. Patination in decorating products is an imitation of the dimming of the surface of the material, which in its natural form looks like a color change after a sufficiently long period of time.

The patina is also heat-resistant, up to 700 ° C in copper color. It must be applied with a stiff brush. The author cuts the hairs from a regular brush. Then it dips the brush in the paint, the very tip and rubbing it on some surface. An almost dry brush begins to patinate the painted surface of the product.

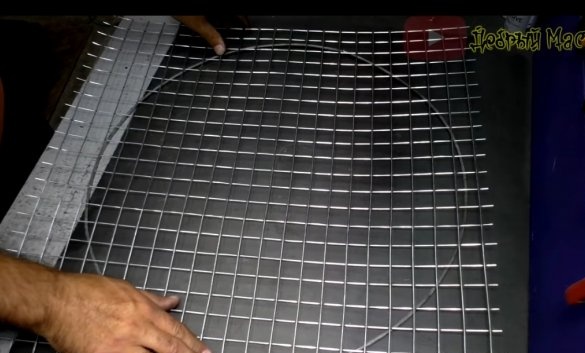

The next steps are making a mesh on the bowl. For the base makes a circle of 4 mm wire to the size of the disk. A metal mesh with a mesh size of 25x25 mm lies on this circle. It is welded to the wire. This must be done very carefully, as the wire rods are very thin and can be burned. After welding, unnecessary parts of the mesh are simply trimmed with a hand tool.

The result is such a wonderful thing. It can be used just like an ordinary street hearth, sitting in the evening in front of a blazing bonfire, listening to the crackling of logs and watching a swarm of sparks striving into the night sky. And when you get tired of watching the fire and the sky, you get hungry, then using the grid, you can roast your own hunting sausages or brown the bread ...

Now the author begins the process of manufacturing the second component of his homemade product. He takes the second disk and begins to clean it from rust. There are many ways to do this, but the author uses a grinder with a wire brush.

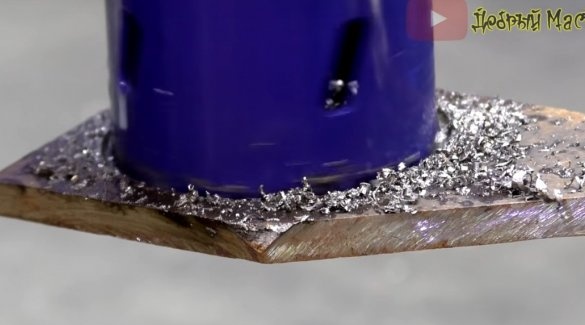

The hole in the central part of the disc must be welded. The patch will be from a metal strip of the same thickness as the thickness of the metal disk. To make the patch round, the author uses a metal crown. Cranks a hole for a center drill and, having lubricated the drilling site, starts the crown, cutting out the part it needs. Welds it.

A tube with an internal diameter of 16 mm is welded from below, and a rod with cut M12 internal thread is inside the plate.

Now tests the resulting design. Screws the adapter into the grill center, and puts a plate on top. Firewood is laid at the bottom of the brazier. After the upper part of the roasting pan - a plate, warms up well, the author tries to cook a meat dish in it. The plate is also good because it can be rotated around its axis, achieving uniform heating. After the dish has been prepared, a handle is screwed into the threaded rod on the bowl and several people remove it from the grill. It is placed on a special stand from a profile pipe and corners.

Here is such an interesting brazier from the author of the channel Good Master!

I wish you all success, new ideas and inspiration!