Polylactide (PLA) is a biodegradable, biocompatible, thermoplastic, aliphatic polyester, the monomer of which is lactic acid. Annually renewable resources such as corn and sugarcane serve as raw materials for production. It is used for the production of products with a short service life (food packaging, disposable tableware, bags, various containers), as well as in medicine, for the production of surgical sutures and pins.

This is from Wikipedia. And PLA, along with other plastics, serves as raw material for 3D printers. Naturally, sometimes it becomes necessary to connect printed parts. The best adhesive for this (according to the Internet) is Weld-On 16. In addition to it, the master had several more adhesives, and he decided to test them all.

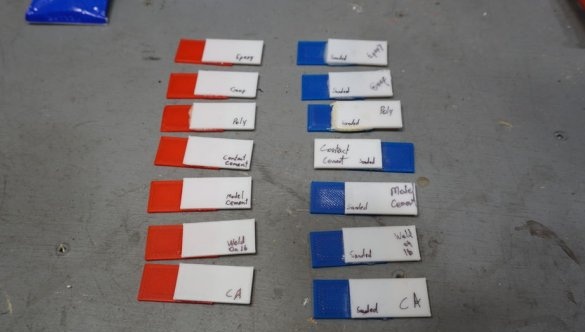

So, the following formulations were used for testing:

-Weld-On 16

Epoxy resin

Polyurethane adhesive

-CA (superglue)

-Universal adhesive (Amazing Goop)

-Cement for plastic

-Contact cement

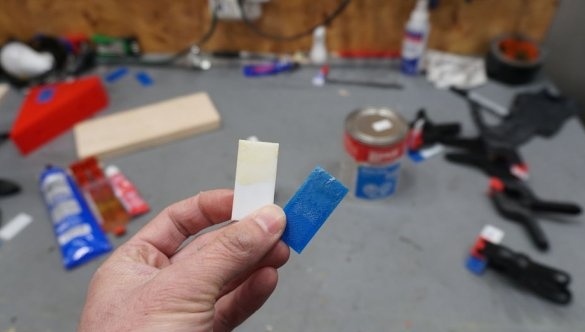

Details for testing were printed on a 3D printer. Each glue was tested with different surfaces, with rough and sanded. Each glue was applied to the surfaces to be glued and left to cure completely according to the instructions. In this case, it is smooth and rough stripes.

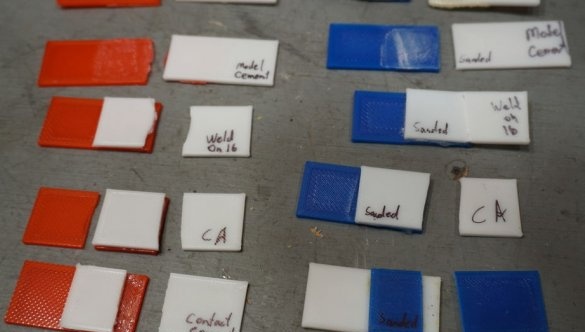

After gluing, the master tried to disconnect the surfaces, and here are the results.

Weld-On 16 - Excellent adhesion, like a solder, the part broke in front of the bonded surface. Very fast action.

CA (Superglue) - Excellent adhesion, PLA broke in front of the bonded surface. Quick action.

Contact cement - Excellent adhesion, PLA broke in front of the bonded surface. Very fast action.

Cement for plastic - Parts are disunited over the bonded surface. Slow action.

All-Purpose Adhesive - Parts come together over a bonded surface. Slow action.

Epoxy Resin - Parts come together over a bonded surface. Drying depending on the amount of hardener.

Polyurethane Adhesive - Parts come together over the bonded surface. Very slow cure.

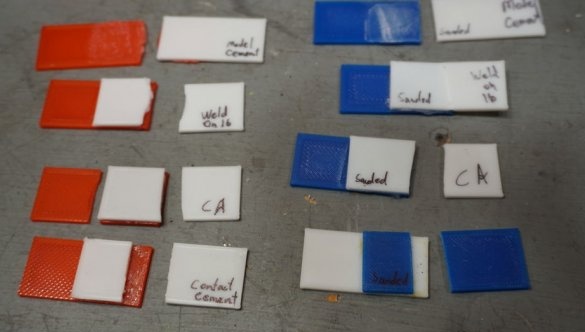

Then the master glued the bars. The master has made the glued surfaces even rougher. The results are as follows (from best to worst).

Weld-on 16

AC (Superglue)

Contact Cement

Epoxy resin

Polyurethane

Cement for plastic

Universal

Conclusions.

The coarser the parts being joined are ground and the harder they are, the better the glue will work, that is, the correct surface preparation.

Weld-On 16 actually melts the PLA. It results in a virtually uniform surface. The master advises that when gluing parts from PLA use the top three adhesives.

How the testing was conducted and its results can be viewed on the video.