I welcome all fans to craft, I propose to consider instructions for the manufacture of a simple copy machine do it yourself. With help homemade you can easily copy different flat parts, the author as an example cut out a protractor. Everything is assembled quite easily, the machine works well and durable thanks to linear bearings. Home-made from plywood is assembled, and the manual mill is the working body. You do not need sophisticated tools for making homemade products, the author even provided the dimensions of the necessary parts. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- plywood;

- manual frezer;

- linear bearings;

- steel axles;

- self-tapping screws;

- bolts and nuts.

Tool List:

- a circular saw;

- drill stand or drill on a stand;

- tape cutting machine (or other machine for cutting plywood);

- tape measure, pencil.

Homemade manufacturing process:

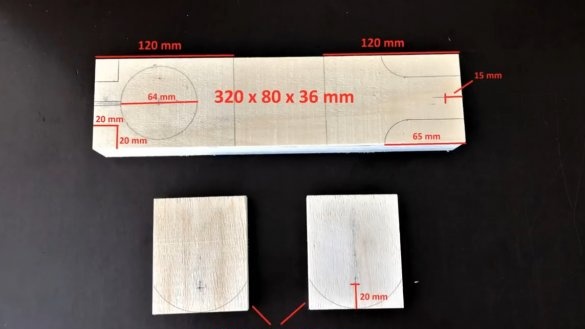

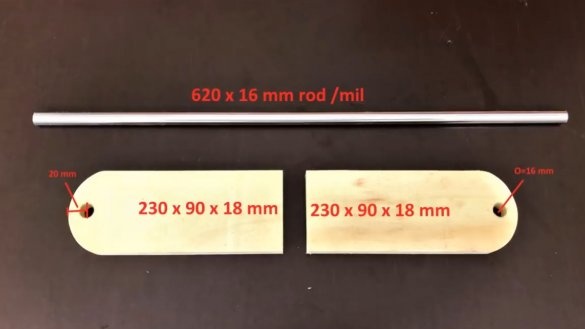

Step one. Cut the details

First of all, we cut out all the necessary parts for the machine. The author used plywood as a material, it is strong, it does not twist, unlike boards and other materials. In the photo you can see the necessary dimensions of the parts.

In the process, the author needed a tape cutting machine, as well as a drilling machine, all of these machines from the author are homemade and also made of plywood.

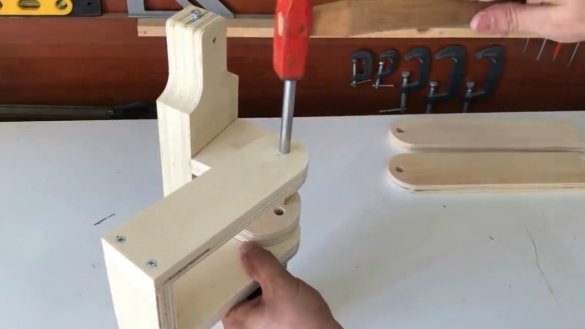

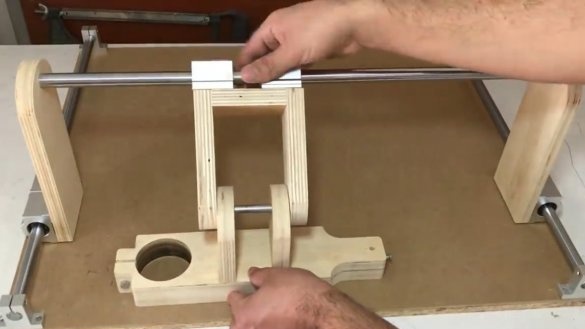

Step Two Putting the joint

When everything is ready, you can assemble the hinge, which will be responsible for raising and lowering the milling cutter, the same hinge is responsible for the angle of inclination of the milling cutter. The side dish is made of two racks with holes for the axis, as well as an element in the form of the letter "P", to which the linear motion bearings are screwed. As an axis for the hinge, the author used a steel axis so that it does not fall out, it can be glued.

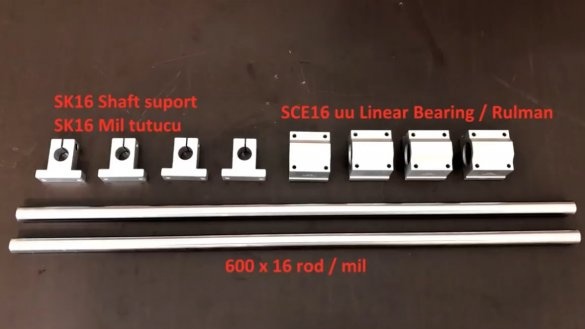

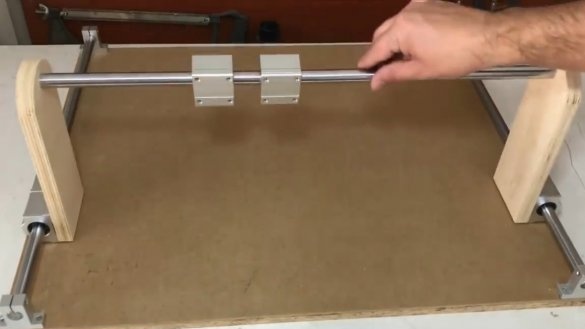

Step Three Put the axes on the base

Next, we need to install three axes on the base, two axes will stand in parallel, they will provide a pull from yourself / to yourself.And another axis will provide the movement of the router to the right / left.

The author used the basis in the form of OSB, on top of which he installed a fiberboard sheet. The axles are mounted using special aluminum brackets.

We attach the third axis to the plywood racks; these racks are bolted to bearings mounted earlier on the axis of the base. The upper axis can be glued into the holes drilled in plywood, or you can fix all the screws with washers.

Step Four Further assembly and testing

At the end, the author cut out the spacer and screwed it between the uprights. After everything is screwed, you can install in the clamp and milling cutter. Not far from the milling cutter there is a persistent axis, which will abut against the copied product. This axis is fixed with a screw, it is adjustable in height.

You can start the tests, as an experiment, the author cut out a protractor. The machine works accurately and quite easily, depending on the cutter used, you can cut copies of various materials, and of different thicknesses. If the material is thick, you can make several passes, gradually deepening to the desired depth.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!