This old ax, made in Japan, has long served as a working ax in the master’s family. The ax is small and it’s convenient for them to hang up the board, hammer a nail and even pull it out. Over time, the ax rusted, became dull, the butt riveted, and the handle faded. Then the master decided to bring him to normal.

Tools and materials:

-Ax;

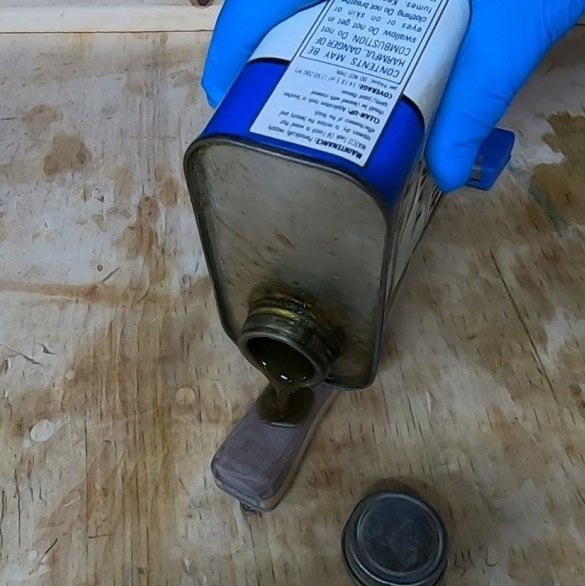

- Rust remover;

-Grinder;

-Knife;

-File;

-Back paper from 120 to 3000 grit;

-Polishing paste;

- Microfiber fabric;

Engraver with nozzles;

- Walnut board;

-Acacia;

- Band saw;

-Super glue;

- Joiner's glue;

Epoxy resin;

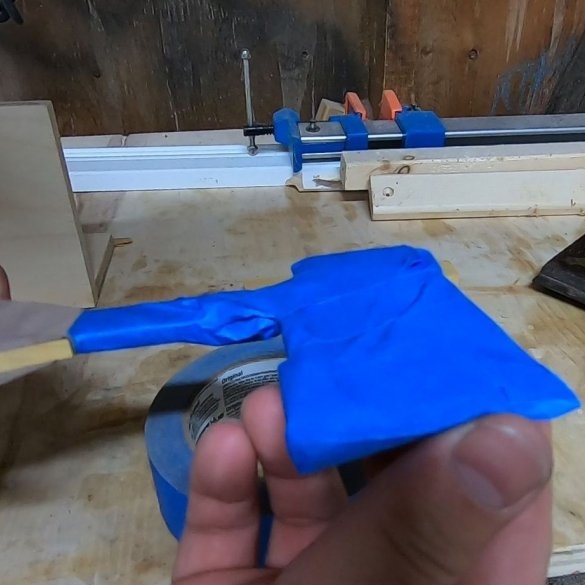

- Paint tape;

- Belt sander;

-Oil for decoration;

-Bars of various granularity;

- A block with a leather belt;

Step One: Rust Removal

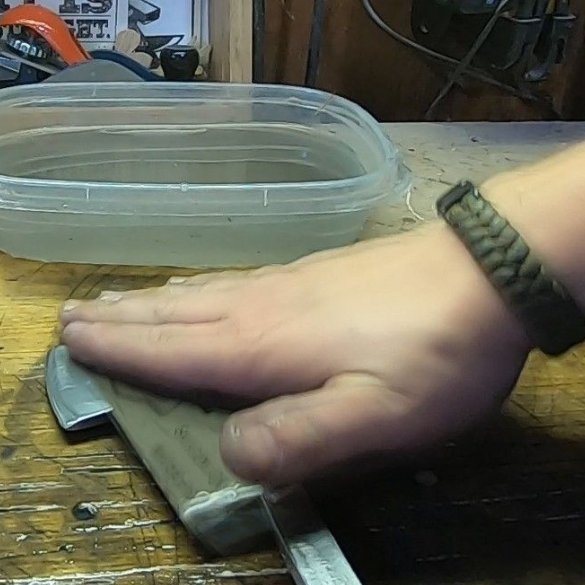

The first step was to remove the rust from the ax. The master pours the rust cleaning fluid into the container and places the ax in it for twelve hours. During this time, the rust should dissolve (depending on the degree of rust and means). The liquid can be poured back into the bottle for future use.

Step Two: Processing

Grasps the old rubber handle. Grinds the metal handle.

There is a cutout on the ax with which you can pull out nails. The master trims the neckline. File aligns the plane of the ax.

Step Three: Grinding

Next, the master begins grinding with water. Starts with sandpaper 220 grit. Grinds until the entire surface acquires the same luster, then uses finer grain paper.

Step Four: Polishing

Apply polishing paste to metal. It polishes the metal, first using an engraver and grinding discs, then using microfiber.

Step Five: Pen

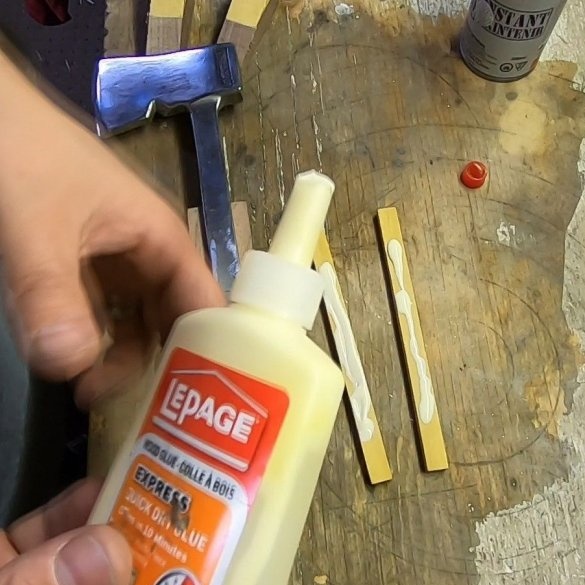

The master makes a handle from walnut with acacia inserts. Sawing blanks. Grinds.

Glue handle parts to the handle of the ax.

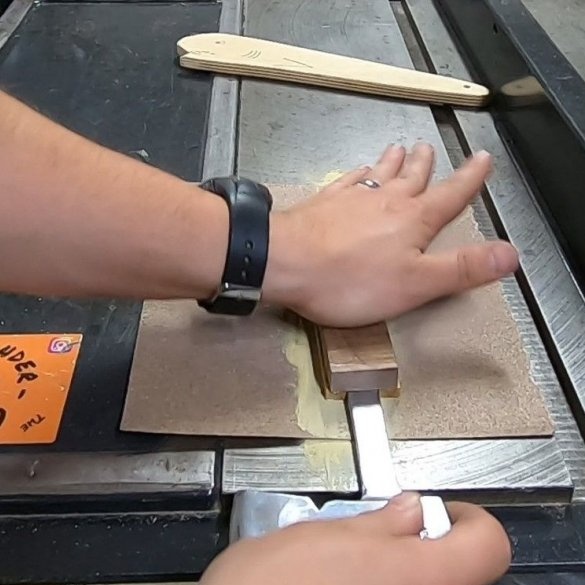

It processes the workpiece and gives it the desired shape.

Tape with metal masking tape. Grinds the handle.

Step Six: Finish

Covers the handle with oil.

Seventh step: sharpening

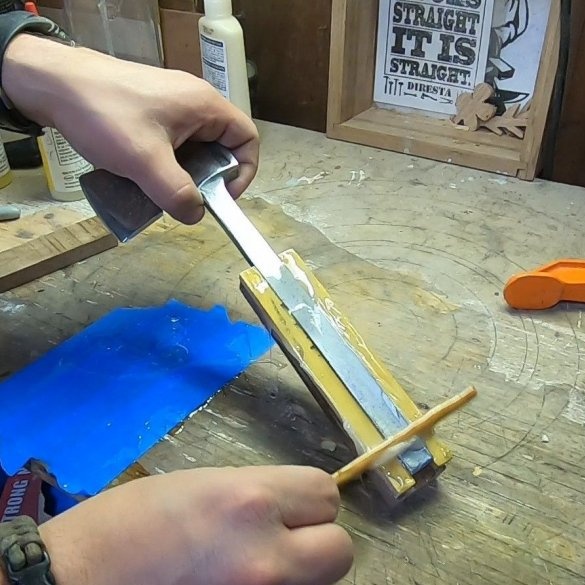

Next you need to sharpen the ax.The master uses whetstones with various grains and water.

Finishes grinding with a leather belt.

Now you can check it in work.

The work is done.

The whole process of restoring an ax can be seen in the video.