I welcome all fans to craft, I propose to consider the instructions for making a simple pump from plumbing pipes do it yourself. Homemade driven by a drill, the height of the water will depend on how to make the propeller. With a simple impeller, as with the author, the homemade product gives out a steady flow of water, it will be enough to wash the car or water the garden if the source of water is close. For the manufacture of the pump, the author used a lathe, but you can completely do without it. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- plumbing pipe;

- tee for pipes;

- two plugs for the pipe;

- conical part for pipes;

- a piece of rubber from a car camera or similar;

- steel rod for the axis;

- sheet steel for the manufacture of the impeller;

- two nuts;

- glue for PVC.

Tool List:

- a hacksaw for metal;

- lathe;

- drill;

- grinder;

- tool for threading;

- scissors.

Homemade manufacturing process:

Step one. Putting the case together

We assemble the pump body, for a start we take a tee and paste a piece of pipe into it. Glue a cone-shaped part to the outlet of the pump to narrow the exit. Well, then, if desired, we glue another piece of the pipe so that you can connect the hose.

Stubs are placed at both ends of the pump, they will also serve as supports for the axis, they do not need to be glued yet.

Step Two Axle and impeller

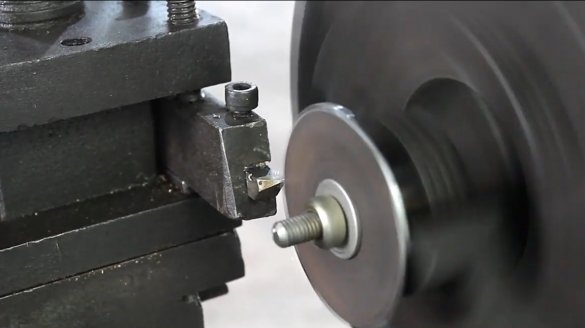

We make the axis for the pump, the author used a long steel rod. At the end of the rod, you need to grind the metal and cut the thread under the nut, the impeller will be mounted here. For such purposes, the author used a lathe.

As for the impeller, we cut out a circle from a sheet of steel, make cuts from four sides, and then bend the blades. That's all, it remains to screw the impeller to the shaft with a nut.

On the reverse side, the author welded a nut with a drilled thread, this will be a support so that the axis does not walk inside the case.

Step Three Oil seal and assembly

In the upper and lower plugs, we drill holes along the diameter of the axis.Of course, the steel axis will quickly eat up the plastic in the plugs, it would be nice to put metal bushings here.

We put an oil seal in the top cap so that water does not drive into the drill. An oil seal can be made from a piece of rubber from a car camera. Just glue the gland to the PVC with a suitable glue. Well, in the bottom plug, the author drilled rows of holes through which water would enter the body.

All parts are ready, glue the bottom cap, put the axis and then glue the top cap. If desired, the pump can now be painted.

Step Four Test

We connect a drill to the pump, and here you can also adapt the motor. The pump pumps perfectly, the water pressure is excellent. If you upgrade the propeller, the water can be lifted at least two meters at a height.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!