In previous reviews, we said that crossbows, slingshot reverse design is much more efficient and powerful than conventional. We will continue the begun theme, presenting this time the manufacture of onions of the inverse construction.

Let's start by watching the author’s video

Let's see what we need to make a bow of the reverse construction:

- wooden plank 15 mm thick and 30 mm wide

- jigsaw;

- drill or screwdriver;

- four clips;

- glue;

- self-tapping screws;

- cable;

- steel plate;

- spring;

- 2 toothbrushes

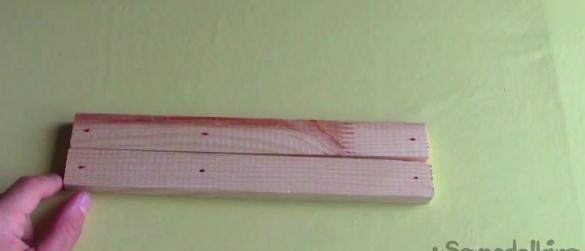

The wooden plank must be divided into four parts to get two pieces of length 30 cm, one 50 cm and another 80 cm.

As the next step, we take two short blanks and in each of them we make 3 holes, retreating 13 mm from the edges, and 11 cm from one edge.

Next, take the middle bar and mark the middle. We mark from the middle 3.5 cm and 11 cm. Also, one hole should be made near the edges.

After that we need 4 clips. From previous materials it is known that such videos can be purchased at the car market.

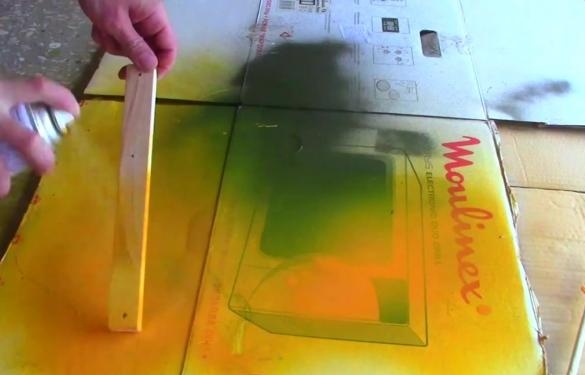

Before assembling the structure, you can paint all the details, as the author of the idea does.

We take a bar that is medium in length and fastens to it long at around 28 cm from the edge. This can be done with glue and a pair of screws.

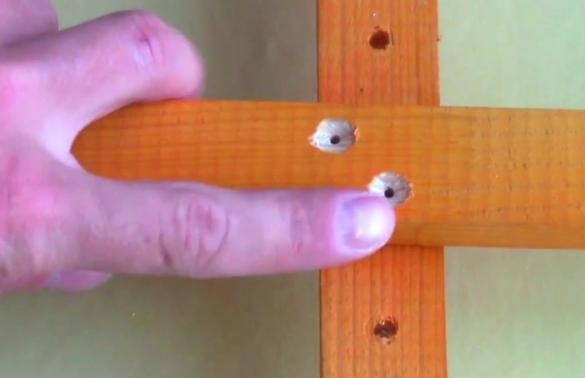

On the edges of the middle plank we fix the short ones, having received the shoulders of the bow. This can be done with a bolt, but here it should be noted that the hole must be drilled so that the bolt enters it tightly along the thread.

We repeat the same thing on the other hand. It is very important that the shoulders move easily and without unnecessary friction.

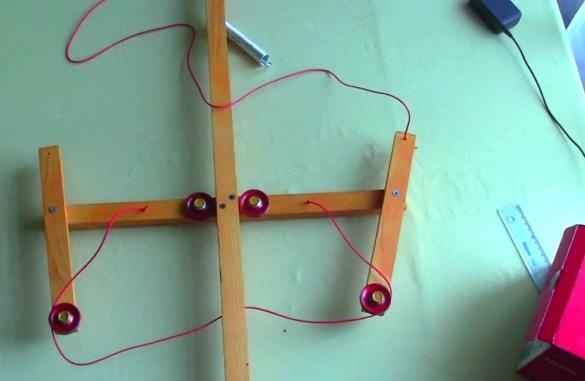

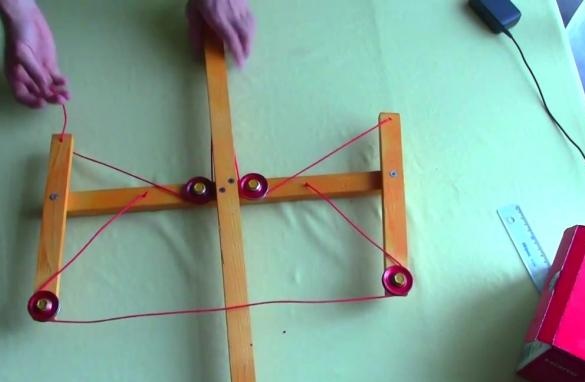

The next step is to take the rollers and fix them on the middle bar and on the shoulders of the bow.

Now you can start installing the bowstring. To do this, you need to make a couple of holes on the middle bar to pre-fix the rope there. After that we thread it through the rollers on the shoulders of the bow.

We turn the structure over and fix the steel plate on the long bar using self-tapping screws.

We attach a suitable spring to this plate.

We take one more piece of rope and fix it on the shoulders of the bow, thread through the remaining rollers and through the spring.According to the author of the idea, the ropes in the structure must be tensioned so that the spring is already in a stretched state before the bowstring is pulled.

The boom stand can be made from two toothbrushes. Such a design will allow the arrow to fly freely from the bow.

On the back you need to add a handle.

You can also strengthen the design with additional springs between the shoulders and the middle bar.

According to the author’s test, the onion tightness is 13 kg.

The design of such a bow positively affects not only the strength of the shot and the speed of the outgoing arrow. When the boom is released, the load on it slowly increases and slowly decreases, due to which it does not deform and the accuracy increases.