Homemade tracked all-terrain vehicle Barsik described by the forum site by Sergei from the city of Pskov under the nickname "Aviator",

became a real textbook for subsequent builders of auto-make-ups, namely, front-wheel tracked all-terrain vehicles with disc brakes

and differential rotation. The forum gives a lot of information about the progress of construction, calculations, as well as a lot of photos and video material.

It started on its own construction March 1, 2011 and was completed by the fall. The construction was done on the experience of Alexei (Tazik-1, Tazik-2) and Yukon, regular readers of the column are already familiar with these all-terrain vehicles.

The original name of the all-terrain vehicle was planned to be a formidable and powerful "Bars", but during construction, realizing that it would not pull on a formidable animal, it was simply called "Barsik" in honor of its beloved cat.

Video

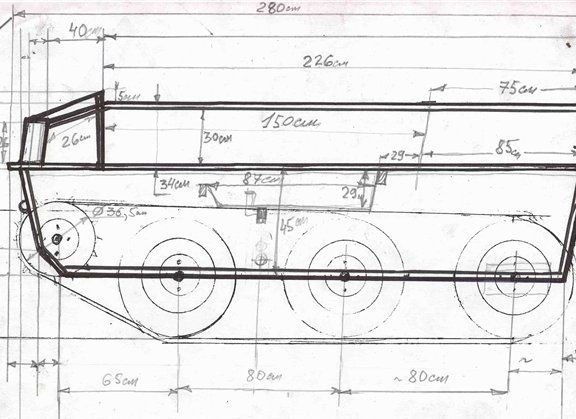

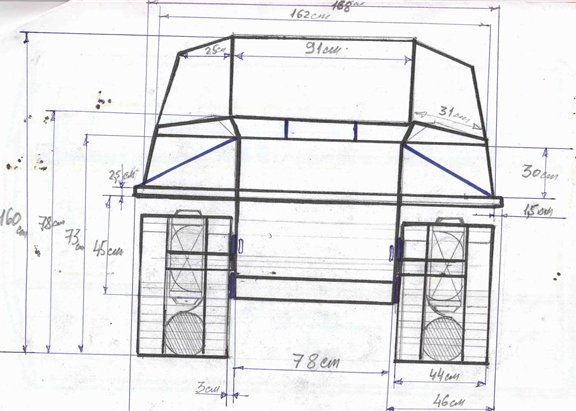

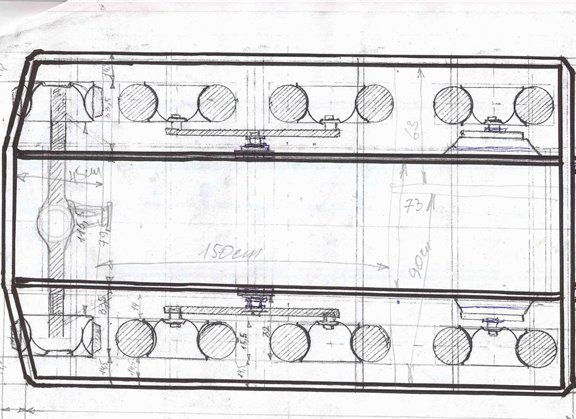

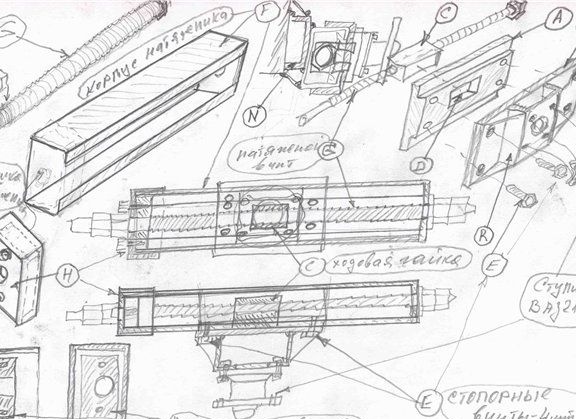

Drawings for the future Barsika.

On Barsik there is an engine from the VAZ 2102.

Accordingly, it is refueled with AI-92 gasoline. Consumption per 100km about 40-45 liters. The tractor’s consumption simply cannot be small, because driving on tracks requires significantly more engine power than on wheels. all-terrain vehicle moves mainly on difficult terrain, at twice reduced gears (2 gearboxes), at high speeds, then fuel consumption is also quite large. If the flow rate is up to 40 liters, we will consider this the norm.

The drive star is made of a wheel disk onto which a 2 mm thick sheet is welded, and then the teeth of the drive sprocket are welded to the sheet.

The tooth of the sprocket is made in the form of an equilateral triangle with slightly convex faces. The teeth of the leading star are made not from the corner, but from segments cut from a pipe with a diameter of 120 mm. The number of teeth is 12, 7-8 tracks are in simultaneous contact.

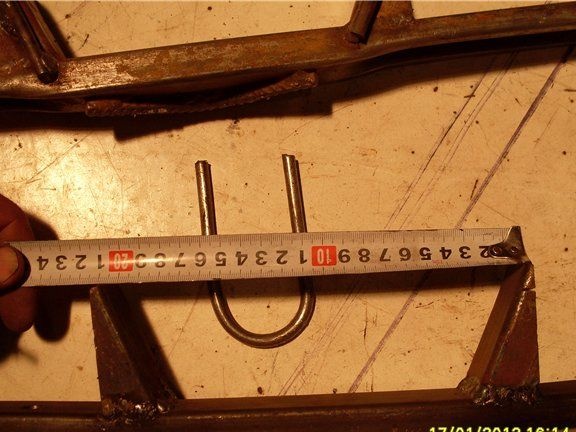

The distance between the fangs of the leading star is 53 mm, the distance between the tops of the fangs is 96 mm. The free space behind the truck between the two canines is 13 mm.

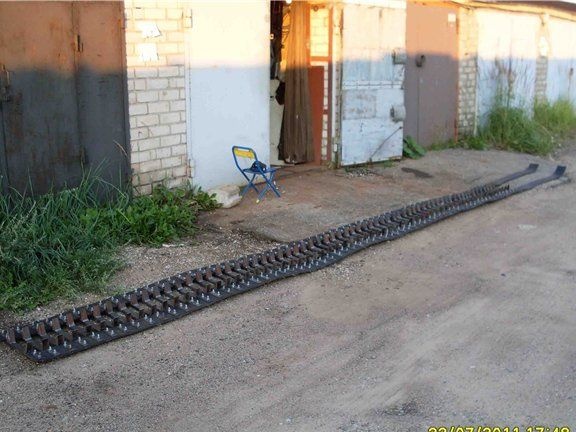

The truck - made according to the classical scheme, as with Yukon and - the profile pipe 40x20x2 mm at the edges is crushed in a makeshift press made according to the Yukon design, the track width is 450 mm, the canine height is 70 mm. There are 60 tracks in the caterpillar.

1 truck assembly, the truck itself, 4 bolts, 4 nuts, 2 platforms weigh 1450 g.

Preparation for trucks.

The dimensions of the tracks redone taking into account the experience of running.

Fitting guide sprockets.

Press for the manufacture of guide fangs.

The guides fit snugly against the driven sprocket, preventing the track from coming off.

The manufacture of caterpillars is the most time-consuming and laborious task in the entire construction of a tracked all-terrain vehicle.

The thickness of the tape is 10 mm, 4 layers of cord. It was bought in St. Petersburg - 7 m long and 500 mm wide. Sawed into 4 tapes of 123 mm wide with a grinder and marking with a white felt-tip pen.

The weight of one track was 230 kg.

Alteration of tracks after running.

Device for connecting tracks, homemade.

Tension mechanisms ready for welding to the body.

The slack axis is welded to the tension mechanism.

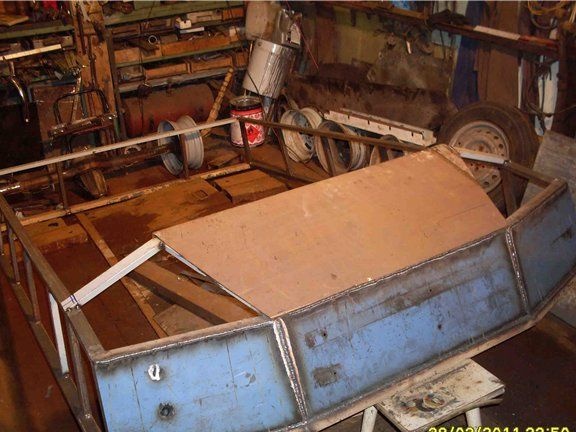

The axis of the tension wheel along with the tension mechanism is welded to the hull of the boat.

The axis of the balancer is welded to the boat and track rollers of the VAZ-2108 wheels are installed.

The front of the all-terrain vehicle is scalded.

Strengthening the balance.

Balancers are shortened by 80 mm after break-in.

Reinforcement after break-in.

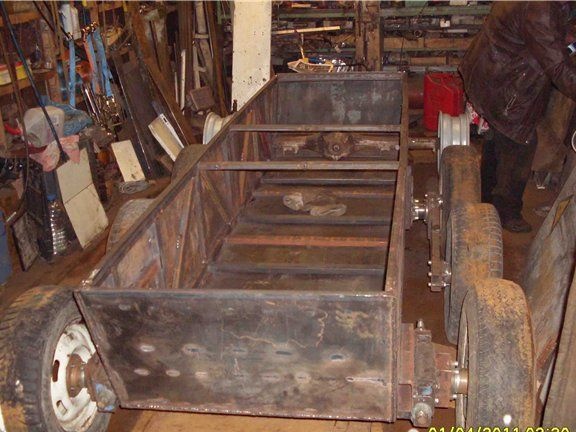

Frame of the future car making on wheels.

Scalded the entire frame of the boat.

The back of the boat is scalded.

The sides of the boat are scalded.

Reinforcement for mounting the balancer axis.

Frame on wheels.

Preparing the rear axle for installation on a boat. The gearbox flips over. Cork and breather are interchanged. The breather is installed in another place, higher. The oil is completely filled in the gearbox, leaving room only for expansion during operation.

Rear axle from the VAZ-2108.

Installing the rear axle and arranging it with a gearbox using a driveshaft.

Cardan shafts are made new, taking into account the experience after running.

Installing an engine from a VAZ-2102 together with a clutch and gearbox. The engine is mounted on its pillows.

The propeller shaft is assembled home-made, the bridge is connected to the gearbox from Mercedes 280, used to reduce the revolutions transmitted from the engine.

The engine from the VAZ-2102.

Long chose the option of landing the driver and passengers. First I went along the path of the "Basin". I tried to put the central motorcycle seat. But I was convinced that the ride on horseback is not very convenient for the driver, and for passengers is generally not acceptable, because there is very little space for their legs (narrow slots along the sides). It is very easy to get a dislocation of the leg, or even a fracture.

Therefore, I decided to put everyone in their own seats. Best of all was the driver. He sits alone in front. Feet slightly spread on the pedals. At the knee level, there are brake control levers, just below the gearbox link. Between the legs under the cover passes the cardan and traction from the wings at the checkpoint, as well as email. harness, gas pedal cable, clutch cylinder tube.

To the right of the driver's seat is the choke lever (choke). The floor of the passengers had to be raised to the upper point of the checkpoint 25 cm from the bottom. Now the floor is absolutely smooth, wide and safety. The passenger seat frame is mounted on two bolts and has the ability to lean forward. For two passengers, the frame has 2 seats, for three - another easily removable frame for three seats. Very comfortably.

Crossbars for fastening seats.

Mount gearbox to the floor of the boat.

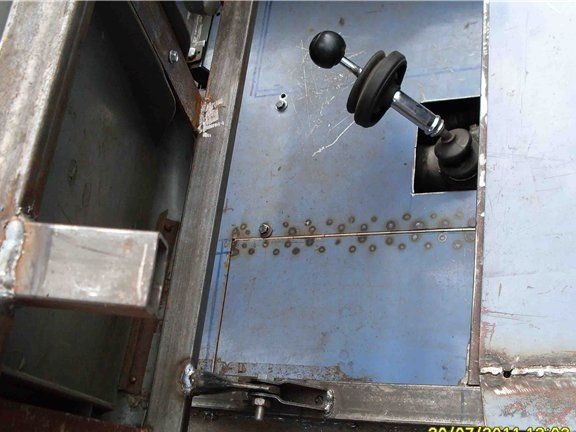

Track control all-terrain vehicle control levers in the driver's cab.

The floor under the feet of the driver and passengers.

Passenger seats.

The seats recline.

Access to mechanisms through hatches.

Two fans are installed in the engine compartment for suction of hot air and forcing in the cavity between the bottom of the boat and the floor to heat the feet of passengers and the driver.

Gearshift lever

Battery Compartment

The engine compartment is closed by two covers on gas cylinders that open from the sides to the central longitudinal jumper. The central part of the stern is occupied by the engine. To the right of it, on a fenestrated shelf, is a gasoline truck from the UAZ at 39 liters. Since the gas tank did not occupy the entire volume of the compartment, it was possible to build a small luggage compartment for wrenches and other small things above the gas tank.

On the other side of the engine on the track, a large luggage compartment was obtained, in which a pump, an electric compressor, a jack, a cable, a hand winch and many other "junk" needed on the road easily fit. The exhaust pipe, as well as the crankcase ventilation pipe, is removed through the tailgate. A silencer is welded to it.To protect from rain, they put a folding frame on which the awning will be pulled. When folded, the frame forms the sides of the cargo platform above the engine compartment.

Refinement of the guide fangs after the break-in.

Having removed the tracks, they decided to exclude getting into the tracks of water and dirt. Since the trucks are hollow and have a rather large volume, we blew them with foam through the holes from the ends. For 120 trucks, 3 large foam cylinders were used.

Dismantling an all-terrain vehicle for painting.

Engagement of tracks on an asterisk.

Units are removed by finished units.

Primer boat.

Removing the engine assembly with the clutch, gearbox, radiator and electric harness.

Engine removed.

Painting the body and assembly as it dries.

Assembling a driver's seat.

Engine compartment

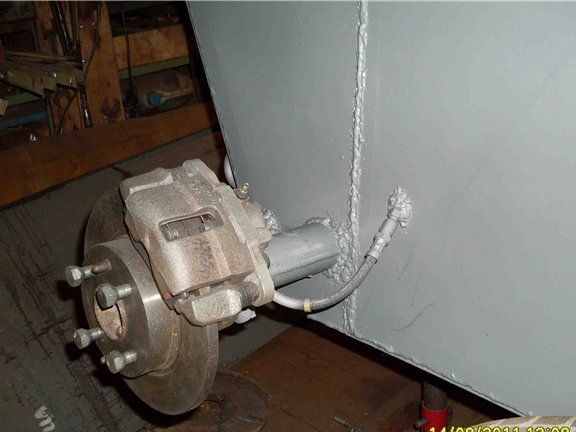

Disc brake system.

Handkerchiefs for reinforcing the rear axle stocking.

Mounting the axis of the balancer.

They painted Barsika with three-in-one paint, primer-enamel on rust of gray and green. I photographed the banks. Looks like not bad. It was a pity to apply camouflage spots. Let’s leave it in such a coloring. The entire device took 6 liters of gray paint and 3 liters of green. Gray was painted (primed) in three layers. Then over the green.

Installation of additional vacuum chambers was required after break-in.

Levers of management of brake vacuums.

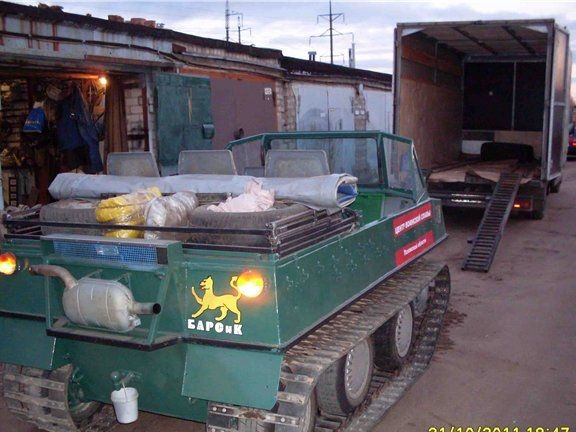

Tracked all-terrain vehicle is ready for further tests.

Barsik hugging with its creators.

The first trips are pleasing to the eye. video.

Dimensions "Barsika". The height of the boat from the bottom to the fenders is 450 mm, the height of the upper superstructure is 350 mm, the length from the front of the power bumper to the rear of the power bumper is 2800 mm plus 200 mm to the protrusion, which covers the muffler from damage. The width along the upper part of the apparatus is 1600 mm, the width along the power harness is 1700 mm, the width along the outer edges of the tracks is 1800 mm. Ground clearance-300 mm. The width of the boat is 800 mm. Each track has 60 tracks. The length of the conveyor belt per track is 6200 mm. The caterpillar is overlapped under 3 tracks, 12 bolts. The track width is 440 mm, the track width is 480 mm. The track's canine height is 70 mm, after bending the upper edge is 60 mm. The track is attached to the conveyor belt with 4 M10 bolts, through 2 platforms. Total for 2 tracks in 120 tracks, it took 500 bolts, 500 nuts, 240 sites.

Balancers, bottom view.

Tension mechanism, bottom view.

Additional brake discs are installed on the rear axle support.

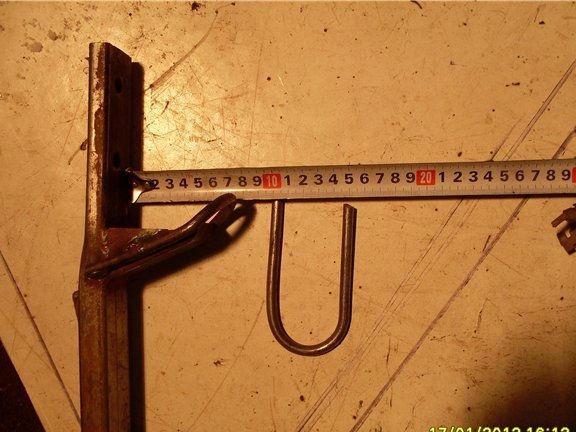

Drawings of the tension mechanism.

The implementation of the inscribed on the drawings.

Headlights installed.

Installed dimensions.

On the tests.

Barsik is ready for further feats.

A very glorious battle path "Barsika" can be tracked on the forum

in which the all-terrain vehicle Sergey participated.

in which the all-terrain vehicle Sergey participated.

These are already stories for other sites. Good luck to the builder of car makes Sergey in his work.