Tracked all-terrain vehicle"Project N1" from Mikhail Dimitrov from the Tomsk region. On the site "" he is registered under the nickname "Michael_83".

A short video about an all-terrain vehicle.

[media = http: //www.youtube.com/watch? v = iTe-2oh8GGc]

All terrain vehicle already built and made it possible to diversify the life of its owner. He participated in many trips to the inaccessible lakes and swamps of our country. Much has been written about this on the website and a lot of video material has been shot about the beauty of the Tomsk Region. How did it all start?

With the excitement of a hunter and fisherman. We needed unsinkable and all-terrain vehicles. I had to create everything do it yourself.

Dimensions of the all-terrain vehicle turned out:

Height is 1850 mm.

Length is 3900 mm.

Width is 2070 mm.

The donor was the VAZ-2101, it was taken from the engine, gearbox (gearbox), rear axles.

The suspension is independent.

Friction control.

Welded frame and boat.

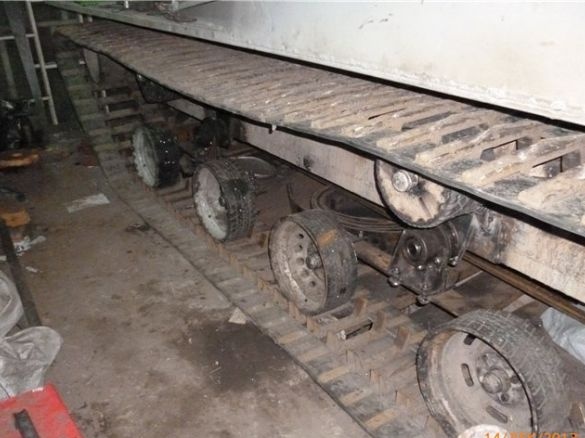

Two rear axles welded together transmit torque separately to each drive wheel.

Track rollers with independent suspension sprung spring. (first option)

The engine from the VAZ-2101.

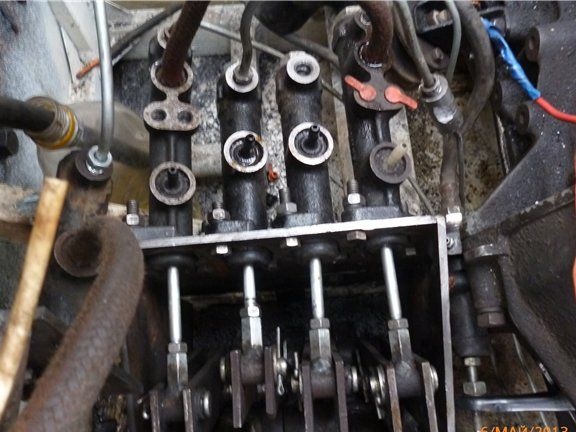

Two reduction gearboxes are installed in series.

The engine is installed in front of the boat, the radiator inside the boat, rear sprocket drive.

Friction clutches are made of VAZ clutches converted into double-disc clutches.

Clutch box. Clutch couplings are installed inside, which interrupt the transmission of torque to one of the rear axles, as a result of which the all-terrain vehicle rotates, the operation of the drive sprockets is synchronized using a chain transmission. Chain pitch Z-19.

Release bearings sit on the input shaft from the Oda, as they are longer than the VAZ drives.

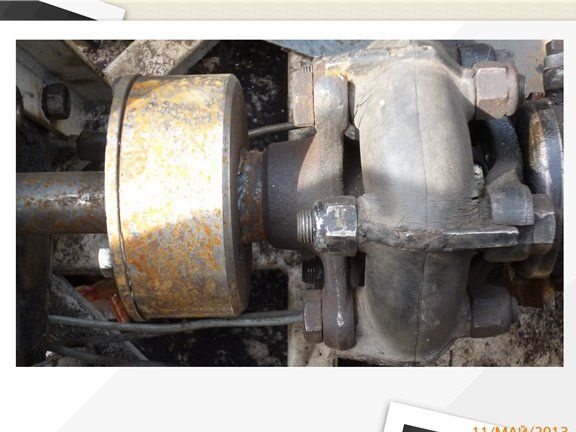

Calipers for braking are installed on self-made propeller shafts.

Hydraulic braking, disc.

Hydraulic clutch and brake control system.

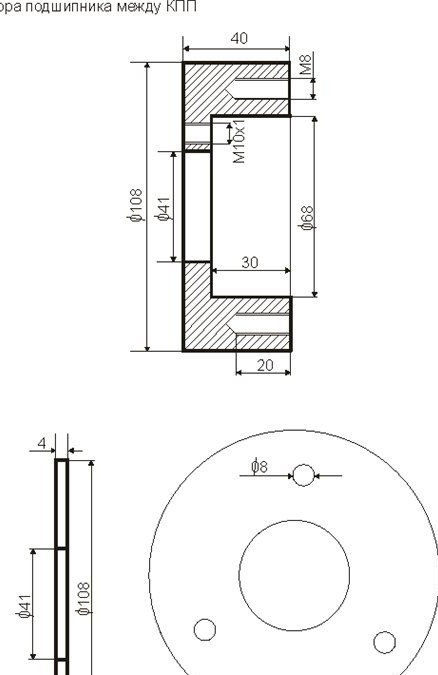

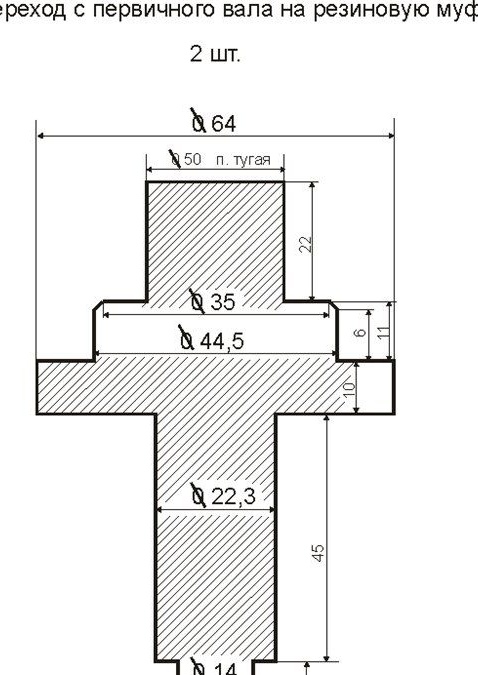

Connection of two gearboxes (gearbox). An intermediate support for the bearing is made.

The suspension is completed and the boat is primed.

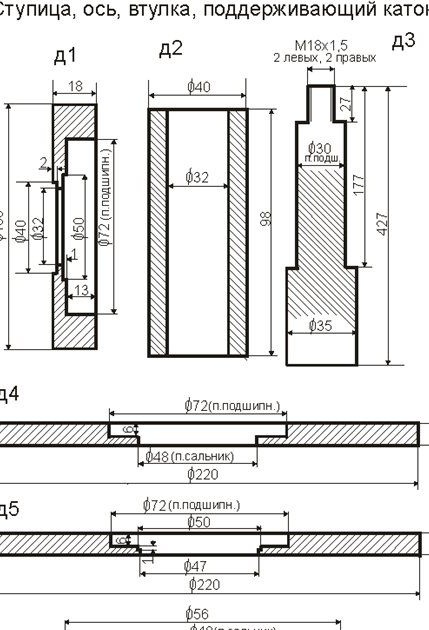

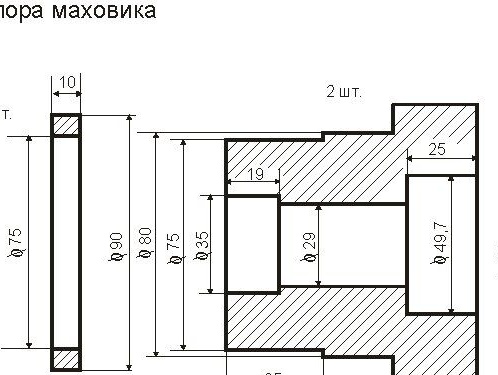

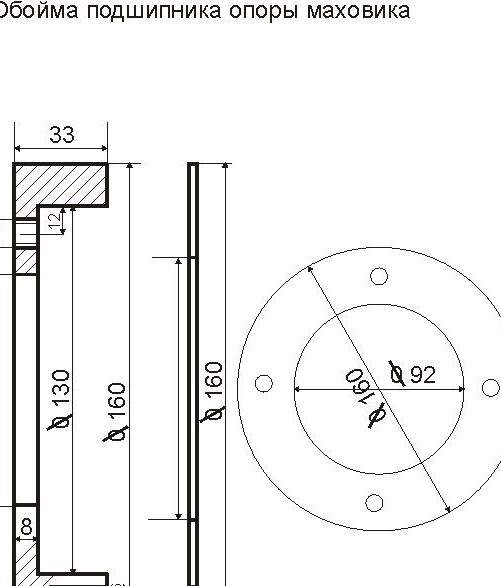

Scheme of manufacturing supporting rollers.

Part D1 is welded on both sides from the outside and from the inside to part D2 in diameter 40.

Part D6 is welded to D4 from the outside in diameter. 48 is the seat for the gland.

Parts D4 and D5 are connected by three M8 bolts to part D1.

In the D5 part, the D47 hole is made for the VAZ hub plug.

Installation of fuel tanks.

First exit from the garage.

The first exit from the garage. video

[media = http: //www.youtube.com/watch? v = cqhh0LRSm40]

Running in the forest.

[media = http: //www.youtube.com/watch? v = lhnceQSC-BM]

A lot of videos about running in. I’ll give a link at the end of the article, there is not only a run-in, but also hiking and the beauty of nature.

Body trim.

Installation of the rear door.

Covering the front of the all-terrain vehicle.

We teach to swim an all-terrain vehicle. video

[media = http: //www.youtube.com/watch? v = PlfI3CKs7vg]

After running in, I decided to change the spring suspension to balancer to get rid of weak springs taken from the VAZ, which collect dirt and grass on themselves. The axle of the balancer is installed.

I put the hub on the axle from the UAZ.

Finished balancers.

Fastening the axis of the track roller to the spring from KAMAZ 18 mm thick. Spring will be the balancer.

The mounting scheme of the track rollers and the axis of the balancer to the hull of the boat.

The work of the balancers.

Running redistributed.

Due to the stiffness of the stroke, he switched back to pneumatic wheels on track rollers, which required the modification of fangs. video.

[media = http: //www.youtube.com/watch? v = a406Ra_rWgw]

Alteration of the guide fangs on the track.

The moment of manufacturing guide fangs.

Running through the winter forest. video

[media = http: //www.youtube.com/watch? v = lUWp045ZMuo]

The driver's cab.

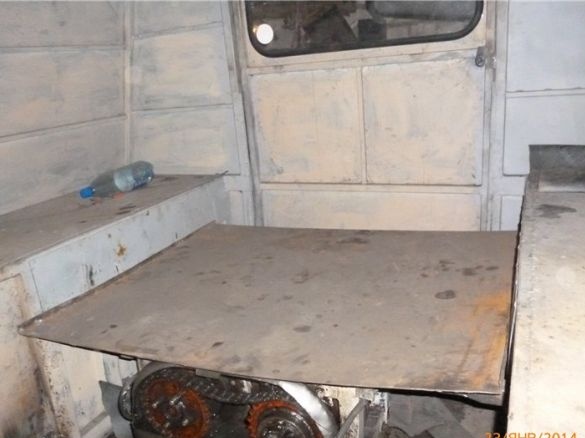

Seats for passengers and cargo.

A large volume of the cargo compartment.

The cabin is painted, a windshield is installed, all devices are displayed on the board.

The cargo and passenger compartment is painted.

Crashed into a side panoramic glass.

He installed the headlights and brought the muffler to the wing.

The all-terrain vehicle comes slowly to its final form.

A lot of videos about snow tests and conclusions made on the site

The star pitch is increased and finalized taking into account the stretching of the conveyor belts from which the tracks are made.

Shipping car making in the back of the GAZ-53 to the place of future tests.

A very fascinating story about trials and trips through the forest, I lower the swamp, those interested can watch and read.

Metal teeth are installed on the star.

Test moment accompanied by UAZ. Wheels in chains.

Very high quality Russian clay.

Currently, the all-terrain vehicle is working to the delight of its owner Mikhail Dimitrov, who is uploading new photos and video reports from his fascinating trips.