On the forum site he writes under the nickname "Kulibin64".

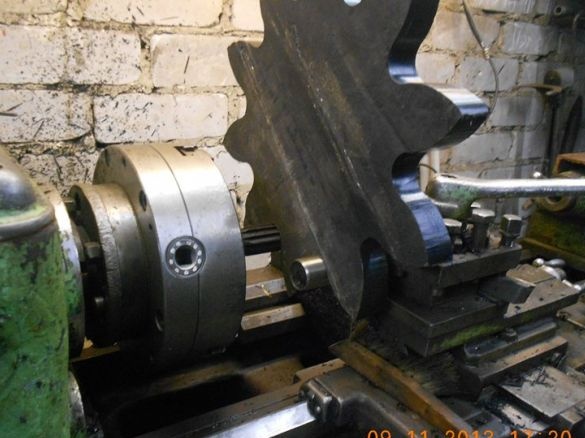

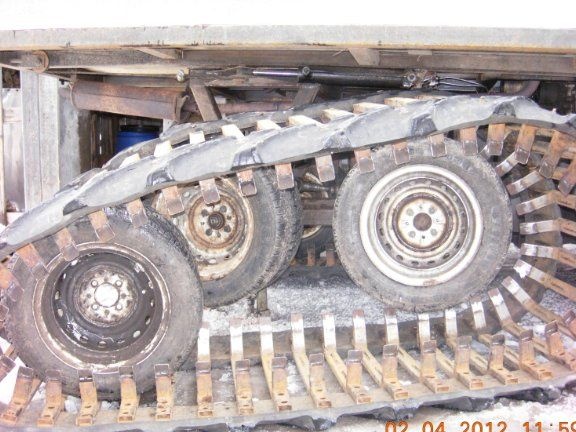

Four tracks on an all-terrain vehicle, support wheels on balancers.

Video about the device car making.

Dimensions turned out after many alterations.

It all starts with a frame. On the frame are two leading bridges at once.

Installed radiator.

A diffuser with an electric fan is installed to the radiator.

A drive to the power steering from ZIL-130 and a generator of 110 Am through a belt drive was taken from the engine pulley.

Engine from a VAZ-21093 together with a clutch and gearbox (gearbox) Top view.

Power steering pump from ZIL.

Distributor from "Iveco" (steering rack).

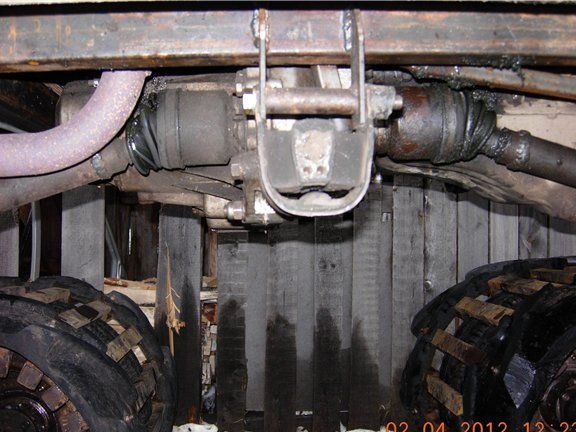

The cable node to ensure the rotation of two carts, works by the method of dissolution on timber trucks.

Work with electrical wiring.

Torpedo installed.

Belt drive from the crankshaft pulley.

A radiator and fan for heating the kung are installed.

Engine installation moment.

Homemade gearbox for applying rotation to both axles at once. Gear ratio-1, spur gears from a tractor gearbox (pig) of a winch drive from DT-55.

Drive propeller shaft to the rear axle from the VAZ-2107.

Guide fangs to prevent track crawl. Caterpillars are made of tractor rear wheel tires.

The caterpillar is pulled by inflating the wheels. The wheels are dual on each axle. In total, the all-terrain vehicle took 24 wheels.

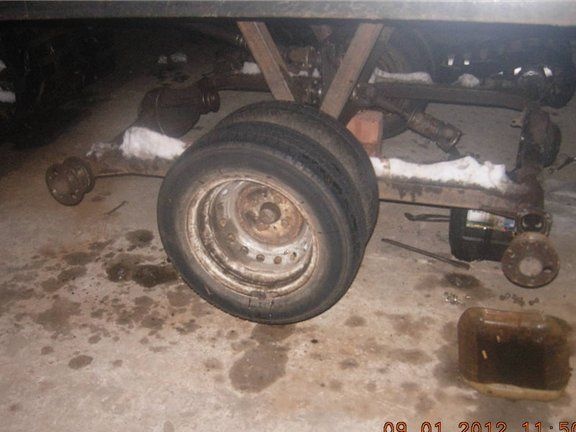

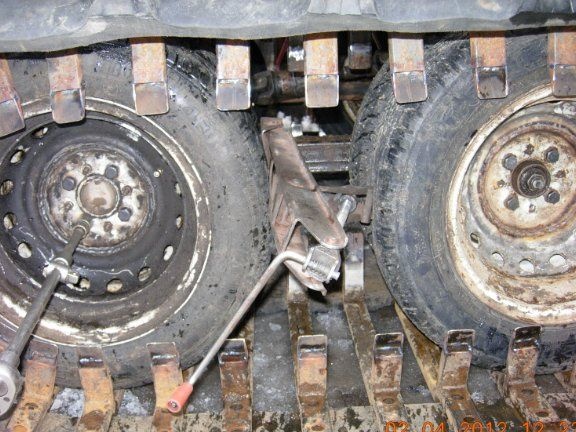

The middle axis is made of front wheels from the VAZ, the disks are cut, turned over and welded.

Discs flip to each other.

Attached to one axis.

The second part of the undercarriage is attached to the main carriage on the principle of a tractor unit, and two tapered bearings on the kingpin.

Stove for heating kunga.

Work has begun on the kung.

Iron for sheathing kung.

Welding the kung frame.

Strengthening the cross members of the kung frame.

The front wall is riveted.

One side is riveted.

Dimensions in comparison with Matiz.

Inside view of the kung.

Covering the rear wall.

Installing a radiator in a kung.

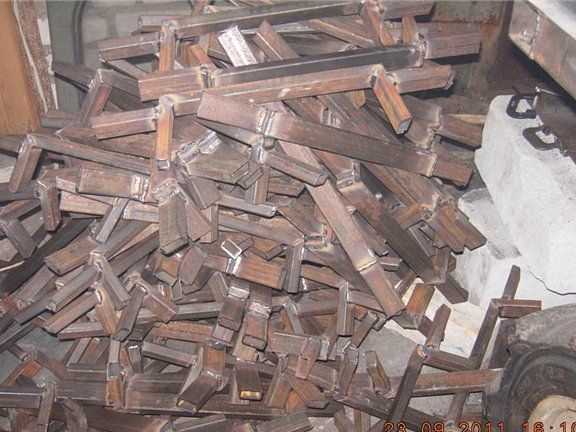

Equipment for the manufacture of a second set of tracks, better on cross.

Conductor for welding tracks for a new track.

Blanks for trucks.

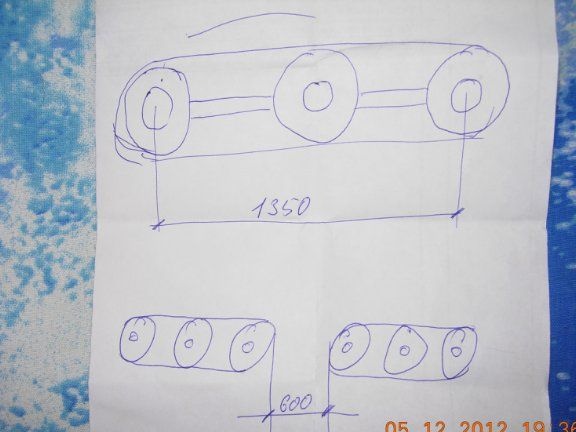

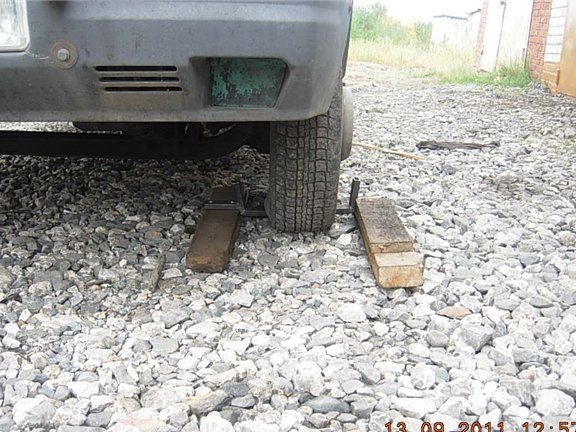

Truck test with a car weighing 1950 kg.

The tracks are welded.

Stacked up.

Round off the ends of the guide fangs.

The tire is cut in half.

Using a jigsaw, the tire is cut.

The caterpillar is going.

The caterpillar is assembled and dressed on one side.

On wheels, pacifiers are inflated for pumping wheels.

The third caterpillar is assembled and dressed.

The width of the new track is 730 mm.

The weight of one truck is 1 kg 300 gr.

Rubber weight 50 kg. 44x1.3 = 57.2 weight of the trucks. Total 107.2 kg track weight excluding bolts and nuts.

The last caterpillar is dressed.

Pokatushki on the new caterpillar. video.

Attached rearview mirror.

Moving through a log. video.

Shock absorbers act as limiters.

Shock absorber mount.

Reworked dashboard, wiring from the VAZ-2106.

Installed stove in the cab.

The speedometer is installed.

The tachometer is working.

Brew differentials in bridges.

Shrinkage in the snow. A line in the middle of the crankcase of the bridge.

Winter trip.video.

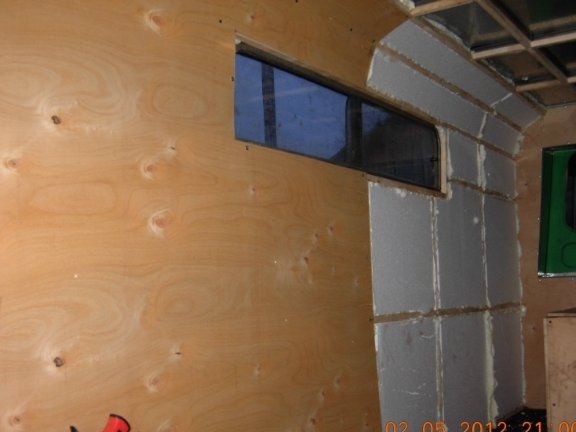

Inserted side windows in the kunga.

Drive axles from the engine VAZ-2108.

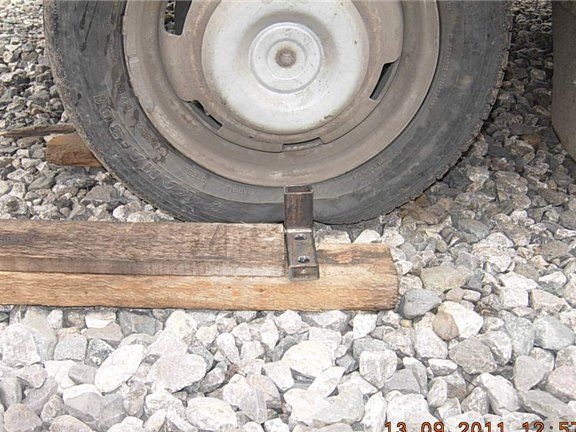

Installing tracks using a jack.

The pipe from the stove is removed from the kung.

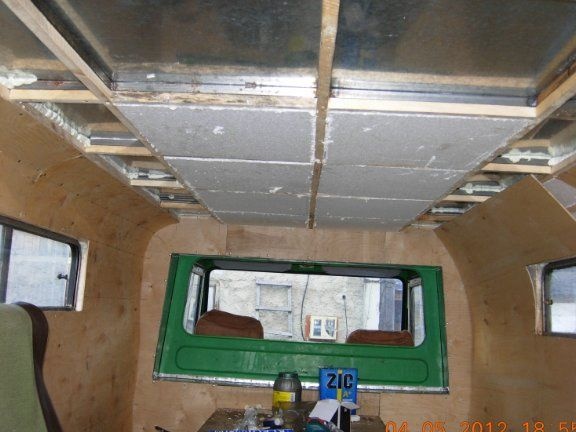

Inside the kung are wooden slats for insulating walls from the inside.

Pasting with insulation and foam.

The window in the back door is embedded.

Sheathed with plywood.

Seats will find their place.

Roof insulation.

Each all-terrain vehicle has its own pit.

Total weight of the all-terrain vehicle turned out 2540 kg.

Place for a jack.

Good jack.

In this pit, the axis of the satellites broke and tore the gearbox housing. Jacked out.

Here is this pit. Do not call here anymore. Video.

Ball bearings on gearboxes are replaced by roller ones.

Oh, the roads ...

Bucky finished.

Tanks are installed on the sides.

Our "kulibin64" is a noble laborer.

You can read the article in, it is already in the archive. March 29, 2013.

Attached a stop on the door.

I decided to install the leading stars. Blanks.

The star is collected and on it tracks, tracks from a pipe 34x2.8 mm.

Truck and manufacture.

Centering rings on the star will prevent lateral wear of the tooth.

The tape is pulled and prepared for cutting.

The conveyor is chopped.

Assembly process.

Rubber lugs.

Caterpillar inside.

Rubber lugs installed.

"Pretzel" wound up. These are the restrictive fangs of the tracks.

Ready tracks.

The caterpillar is going.

Sizes between fangs.

Device for bending pretzels is welded from two piston fingers.

Caterpillars are being made.

Rolled out a cart to replace the tracks and install the lead star.

Setting the drive sprocket.

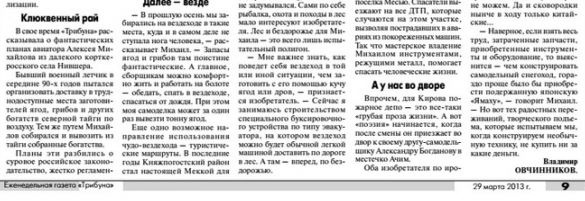

The moment of manufacturing the sprocket on a lathe. video.

1) we outline the location of the base of the tooth.

2) drill a hole in the base of the tooth.

3) the workpiece is ready.

4) we hook an asterisk to the caliper hole.

5) turn on the machine with a mill.

Question: Where to get such a piece of HDPE? Kulibin64 shares his secret.

A piece of pipe is taken to make a star in size and placed in the oven for 1 hour 30 minutes at a temperature of 250 degrees. Time depends on the thickness of the pipe, here a piece of 480x480x30 mm.

Material readiness is checked from time to time with an awl. The board should be taken as little as possible, since under it it is not warming well.

We put the finished mass under oppression with a load or clamp.

Hubs received. Work continues.

The axle shafts are ready.

Going frame.

Assembled a bridge with leading stars.

The truck is fitted to the star.

The drive axle mount is raised above the main frame.

The frame is boiled and strengthened.

Caterpillars dress on wheels and a leading star.

The track tension mechanism is ready.

The track tension mechanism is welded to the frame.

The cart is done.

Places for welding the tension mechanism are reinforced and welded.

Intermediate support and caliper for the parking brake.

Wheels are assembled and pumped up.

The first cart is ready to install.

Cart transportation to an all-terrain vehicle.

A trip with one converted cart. video.

The manufacture of the second trolley happened in the same way, since they are the same. I won’t insert photos here.

Ready second trolley.

The second trolley is installed.

Leading star and new track on the second trolley.

A ride through the woods. There is a lot of snow.

Video

Stars from PND showed themselves very well when traveling in the snow, but when the time came for dirt, the teeth began to wear quickly, then it was decided to make stars of a different type. The base of the star will be metal, and the erasing surface will be rubber, which will make it possible to change the rubber as it wears,

leaving the foundation unchanged. The production of new stars has begun.

Pattern of stellar stems from sheet iron using plasma cutting.

All this happened in the forge workshop of his friend Igor from the city of Kortkeros.

Hubs of future wheels are welded.

The tooth profile is scalded with iron.

Each tooth will have such a profile.

Then the teeth are covered with rubber.

The teeth are scalded.

Each tooth is fitted with rubber.

Stars are made.

The stars are mounted on an all-terrain vehicle, the tracks are the same.

Making another pair of stars.

Running through the mud showed its good qualities of stars. I drove more than thirty kilometers through the mud.

Running in the mud. video

Work balancers when moving over obstacles.

Welded and installed a new hydraulic reservoir for oil.

Reinforced tracks made and mounted on tracks.

Modernization and improvement of the all-terrain vehicle continues. Follow the topic here.

Topic about caterpillar "Kirovets" can be explored here.

A lot of interesting and informative video about all-terrain vehicle "Kirovets".

We wish success to Mikhail Kirov in the construction of all-terrain vehicles.