In most cases, for the smelting of metals, very complex furnaces are used that operate on wood or coal. One of the authors proposed a unique version of a furnace made from a conventional bucket. Such a simple construction will allow melt such metals as lead, aluminum and the like without any problems. And the stove works from electricity, so there is no need to constantly monitor whether the firewood has run out.

Materials and tools:

- power cables for connecting the furnace (this is one cable for 220V or yes for 120 V);

- a bucket;

- sand and gypsum;

- spray paint that can withstand high temperatures;

- drill and drill;

- electrical tape.

Manufacturing process

Step one. Heating element preparation

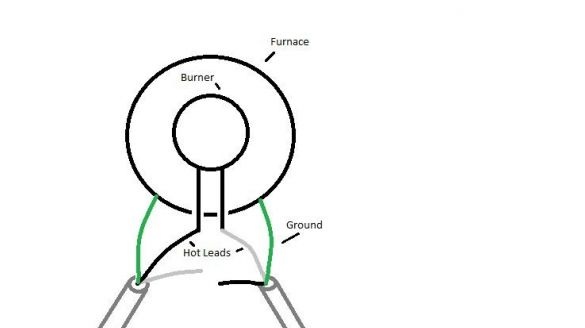

As a heating element, a spiral from an electric stove with a resistance of 28 ohms will be used. In this example, the spiral is connected using two wires of 120V each. It is also desirable to ground the furnace, so its use will be safer.

Step Two Preparation of the furnace capacity

At the next stage, the refractory walls of the furnace are made. A mixture of gypsum and concrete in a ratio of 1k1 is best suited for these purposes. Concrete can also be used, but it is likely that it will not withstand high temperature differences and will crack. When casting a refractory wall, disposable paper plates or foil can be used. Also at this stage, you must not forget about the holes for the output of power cables.

In addition to making refractory, you also need to cover the bucket, otherwise the heat will come out of the furnace.

Step Three Installation of a heating element

the heating element is installed in a furnace that is actually ready for this. The spiral should be freely placed in the furnace. High temperature spray paint is used as insulation. After this, the contacts should be additionally insulated with electrical tape.

That's all, the oven is ready, you can start the first test run. First, the oven must be heated for no more than 20 minutes in the open form, and then allowed to cool completely. The next warm-up is done for 40 minutes.Thanks to this procedure, residual moisture is released from the refractory coating. It is necessary to work with the furnace carefully; there should be no flammable materials near it. Now everyone can cast any aluminum blanks without any problems.