Motosobaka-stretchers from the Tarpan motor-block built by Nikolai from Arkhangelsk. Somehow, on long winter evenings, Nikolai thought. I have a Tarpan walk-behind tractor that works for three days in the spring and there is nothing besides the cutter on it, and I plow all year round. I decided to load it with work in the winter.

He drew and assembled the track blocks for the Tarpan instead of the cutters. The speed, of course, is low -5 km \ hour.

But understeer is easy, as the base is short. Pulls on a stretcher up to 150 kg. On the snow does not fall and does not skid, the caterpillar all the same. Such a scheme can be applied to any walk-behind tractor, even to the “Mole”, only to calculate the diameter of the sprocket and the width of the track depending on the engine power.

The performance characteristics:

The width of the structure is 800 mm.

The width of the tracks is 700 mm.

The body is 700x800 mm.

Two tracks of 80x2300 each from a conveyor belt B-4mm. The cord is single layer.

Tracks from waste plastic pipes.

Axis base -670 mm + tension.

Leading stars are cut out of polyethylene using a jigsaw.

To the motoblock still need to do a sled.

Conductor for caterpillar assembly. The jig is made of an old door with two glazing beads stuffed on it at the edges and 35 mm bars, the distance between them is also 35 mm.

The tracks are dressed on the drive sprocket and on the idler.

Two housings with tracks are connected by corners and on them is a platform for the engine.

Tension wheel with a diameter of 290 mm with a tension mechanism.

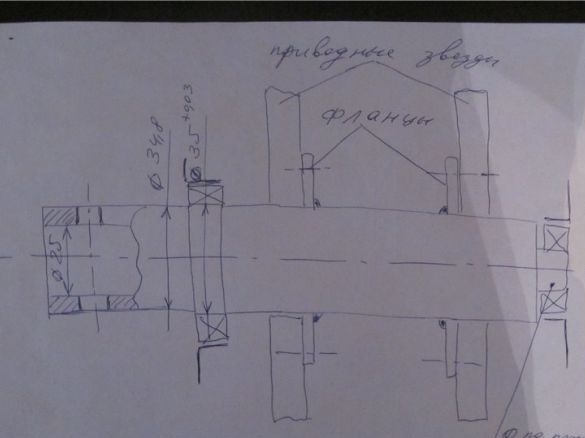

A drive sprocket with a diameter of troughs of 290 mm with an axis that is worn on the axis of the walk-behind tractor.

The rear drive sprockets are made on a motorized dog this way, but sizes that are not indicated must be selected depending on your machine.

Bearings 107 and 205 are used here. Bearings 205 are too big for such a technique, but what was at hand. Bearing per axis depends on the diameter of the axis of your unit.

On the cross corners, grooves are made for fastening.

Inside the sprockets, support skis are made of plastic, which are fixed with screws from the bottom to the sides of the boards so that the ends of the inner ski do not walk and do not straighten

they are fixed with clamps made of round D6 mm.

Operation shows that a 4 mm thick tape with one cord is rather weak, therefore it is better to increase the area of the support by adding another caterpillar in the middle.

A revision of the gearbox and the pads showed that they were all right.

Moments of operation of the motoblock in winter conditions.

The controls are simple and easy. The moment of riding with a child.

Your walk-behind tractor will serve you in the winter as well; the garage.

Nikolai still has a makeshift tractor, but this is a topic for another story.