This is not the author’s first project in terms of mechanical engineering. This time it was decided to use the existing eye as the basis for the future all-terrain vehicle. The goal was to put together the simplest pneumatics for two people as soon as possible.

Materials and mechanisms used to create this all-terrain vehicle:

1) Body from Oka

2) Bridges from UAZ

3) KRAZ tires

4) Profile pipe 50x50x2.5

5) springs from the Volga

6) shock absorbers from the Niva

7) Gearbox from oki

Consider in more detail the stages of construction of an all-terrain vehicle:

Start of construction:

The author started grinding the wheels, a chainsaw was used to cut the necessary tread. peeling itself occurred by cutting rubber layers with a standard clerical knife.

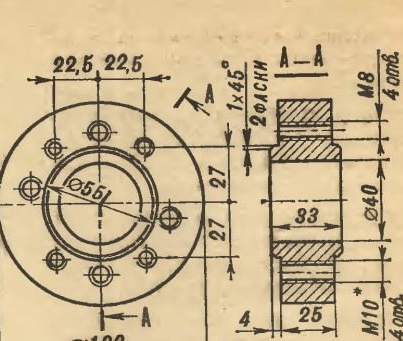

Further, the author faced a certain problem, since the width of the UAZ bridges exceeds the width of the oka, it is necessary either to fit the bridges, which is rather troublesome and definitely will not accelerate the assembly of the all-terrain vehicle, or to make disks with a maximum reach. It was along the second path that the author decided to go:

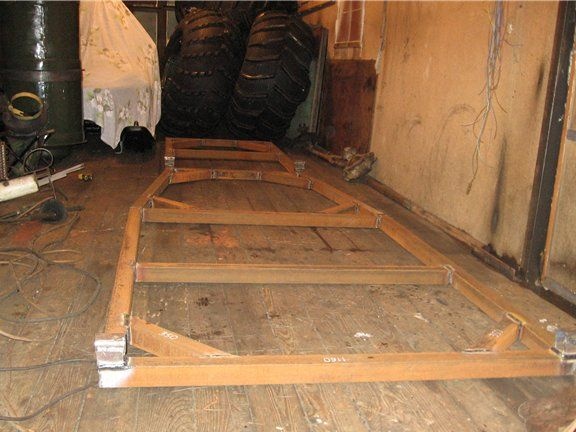

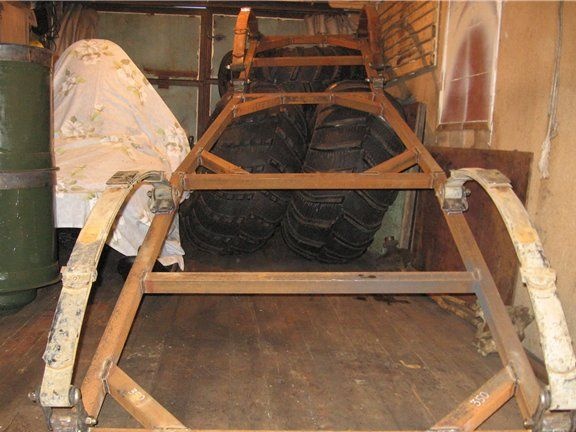

The frame for the all-terrain vehicle was assembled by hand and welded from a square pipe of 50 by 50 by 2.5, and about 20 meters of the profile pipe took the entire frame. the frame was quite light and at the same time strong enough to withstand loads. The weight of the frame is about 50 kilograms:

Further, springs from the Volga were installed, but before that the package of sheets in them was reduced to three pieces. looking ahead, I’ll say that after the tests it turned out that three sheets were still not enough and two more sheets were added back to the spring.

Front axle mount:

Niviv shock absorbers were also installed.

Then work began on the transfer case, it was rebuilt and mounted on the frame:

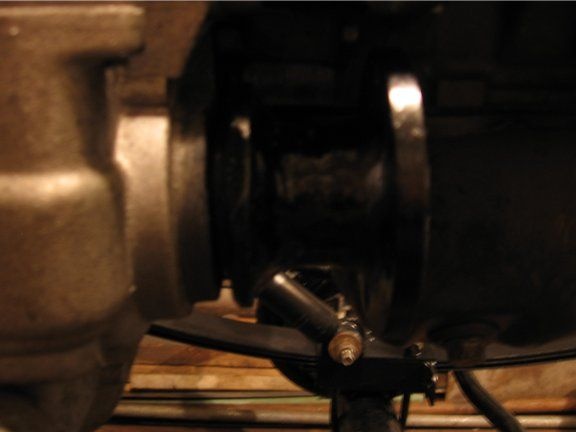

Then the author proceeded to create a connection between the universal joint from the UAZ and the transfer box of the niva. The solution turned out to be quite simple and easy to implement: two flanges from the UAZ and Niva were taken, the working part of the stuffing box was cut from the Niva flange and joined to the UAZ flange, then the structure was welded and the connection was established:

The engine was also rebuilt, washed from dirt and installed in its place in the frame:

In the gearbox from the Oka, the differential was brewed, grenades were also cut off, and flanges under the cardan fields were added to them:

the installation of the cardan and painting of the all-terrain vehicle frame were carried out:

Due to price preferences, the steering from the Volga was installed, although a power steering would not have prevented with Krazov wheels. Therefore, the author plans to install it as soon as possible.

Cardan joint through flange:

All terrain vehicle Feels great both on land and on water, thanks to a well-cut tread on the tires.

The mass of the all-terrain vehicle turned out to be about 700 kilograms.

During a trip along the tundra, the CV joint was broken on the long side of the bridge; after its replacement, it broke on the other side. The reasons for this vulnerability can be different, the load is allowed due to the strong departure of the drives, weather conditions and the quality of the joints themselves.

A breakdown occurred when the second downshift was engaged, the lock was not engaged. That is, there was no load on the all-terrain vehicle, it was decided to replace the entire front axle. In general, the author hoped that such a flyout of the discs would create some problems for the bearings, but after disassembling the following details became clear: there were no backlashes, and the CV joint had no difference with which offset the wheel should be turned. i.e earring turned out because the CV joint was not high-quality and fell apart simply from wear, so the disc out here did not play a role and does not need to be reworked.

Small improvements were made to the all-terrain vehicle:

In particular, steps are installed for a more comfortable fit in an all-terrain vehicle:

The all-terrain vehicle serves faithfully, although there were fears that with a similar departure of the disks there will be problems in the pivots, pins, bearings. However, during use, the bearings on the right side in the front axle were only once replaced, since the stuffing box life was used up. The all-terrain vehicle is operated in an area where the main coating is peat bogs or quartz sand, it was this sand that caused the oil seal to break.

All-terrain vehicle author: Sergey with the nickname "Sanich 89"