Another interesting model all-terrain vehicle assembled on the basis of oki. The author made easy and fast all-terrain vehicle with high traffic, the main purpose of which will be fishing trips.

Materials mechanisms and assemblies used to build this all-terrain vehicle:

1) profile pipe with dimensions of 60 to 80

2) Internal combustion engine from vaz 21083

3) gearbox from the same vaz 21083

4) transfer box from the cornfield

5) the rear axle from the Chevy

6) front suspension from the fields

7) T-150 tires and Arcticktrans f-118

Consider in more detail the stages of construction of an all-terrain vehicle:

To begin with, the author assembled a frame from a profile pipe measuring 60 by 80 and installed the main units of the all-terrain vehicle on it. the engine with the box is located longitudinally in front of the rear axle of the all-terrain vehicle.

Regarding the wheels, the T-150s were originally installed, but since they deteriorate quite a lot, and are expensive in themselves, they also had to constantly work with belts. bolts and ribbons, since it is tubeless, the author decided to replace them with wheels f-118 arktktrans. The ride has become tougher. but in the mud patency improved, tire pressure must be adjusted in the snow.

Wheels:

For all the time of operation of the all-terrain vehicle there were the following breakdowns:

the axle shaft was broken, since it disrupted the spline, satellites of the rear gearbox and a short CV joint was cut off. The cause of the damage was riding in deep snow.

The optimum pressure for the wheels was chosen somewhere around 0.2.

Wheels under the wheels were made independently. used iron 2ka, UAZ hub. rims have an angle of 30 degrees. the rubber is quite tough mainly due to the hard tread in the middle.

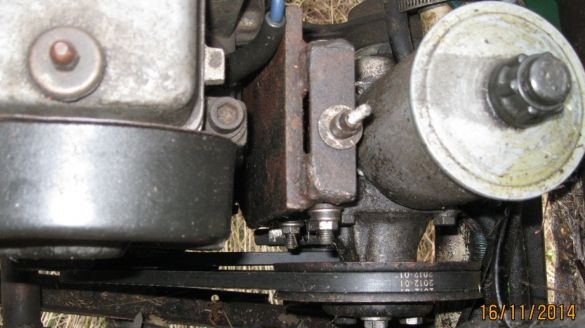

Here is the engine compartment of an all-terrain vehicle:

A gura pump and a square pulley made of two standard ones are installed:

Here is the rear axle:

jet thrust lower standard and upper shortened:

Set transfer case:

Front gear:

power steering from Mercedes:

After analyzing the wheels, the author began work on the bridges of the all-terrain vehicle. The author decided to make suspension on springs. There was a choice between two mounting schemes: hooks with a pan and an A-lever or jet rods.

The application of the upper ball joint from the VAZ was also considered in terms of the hinge of the A-specimen, which could be fixed on the bridge. But the design turned out to be rather unreliable, breakdowns could occur both in the place of the ball finger and simply cut the bolts under load.

Because of the installation of the steering gear, it was necessary to lengthen and strengthen the frame a little, and the gear itself was installed according to the type of UAZ, but backward.

Then the author decided nevertheless to replace the Niva bridges with the UAZ bridges as more durable and reliable. The weight of the reinforced bridge was 60 kilograms.

The rear suspension remained unchanged, the only soft springs from the VAZ 2108 were installed, and the attachment points of the shock absorbers were also changed.

paint work:

After completion of installation and modernization of the front suspension, steering and brakes, test trips were made on an all-terrain vehicle. The suspension on the springs turned out to be very soft, you may need to install compression limiters. the author was especially pleased with the absence of backlashes in the transmission and the absence of any knocks.

Work on the front axle of an all-terrain vehicle:

Cardan looks like this:

the front suspension was made on lower jet rods, the weak point of this design is the ball bearing from the vases. But to understand how vulnerable this part of the machine is, you can only run it.

Front springs from 2108:

Suspension Strut Front 2108 with replaceable cartridge:

Steering gear from Mercedes:

Installed disc brakes from the fields and the caliper from the VAZ 2108:

Shock absorbers:

silencer installed:

At the peak test, the all-terrain vehicle approached a steep bank at a speed of about 40 km an hour, the suspension withstood the load and the ball bearing does not need to be replaced, according to the author.

vehicle interior:

Ready ATV:

Video with the off-road vehicle ready:

The author of the all-terrain vehicle Leonid from the Novgorod region with the nickname "molibden"